Discover how innovative drone technology transforms railway inspections, particularly challenging scenarios like bridges over rivers. Learn how autonomous UAVs streamline the process, ensuring safety and efficiency.

Project Background

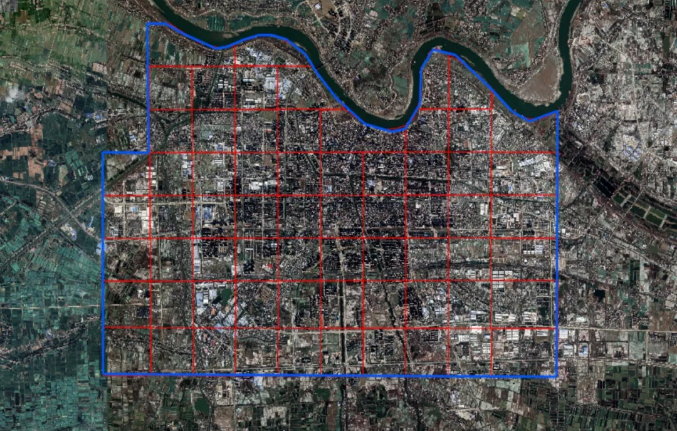

Imagine a railway stretching over a river, presenting formidable inspection hurdles. With a length of 320 meters and a narrow bridge width of 7.5 meters, traditional methods fall short. Embrace the solution: employing UAVs for autonomous inspections, ensuring safety and efficacy.

Achievements

1. Visual Clarity: Our images vividly depict crucial railway elements, from steel rails to ballasts and track sleeper numbers. Witness the pristine condition of connecting components through clear visuals.

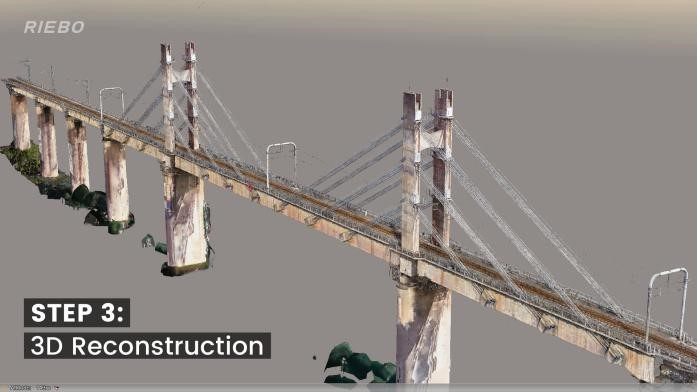

2. 3D Reconstruction: Experience a comprehensive visual representation of the railway's condition through advanced 3D reconstruction technology.

Equipment Utilized

- RIEBO high-resolution medium-format inspection camera

- DJI M300

- RIEBO Route Assistant

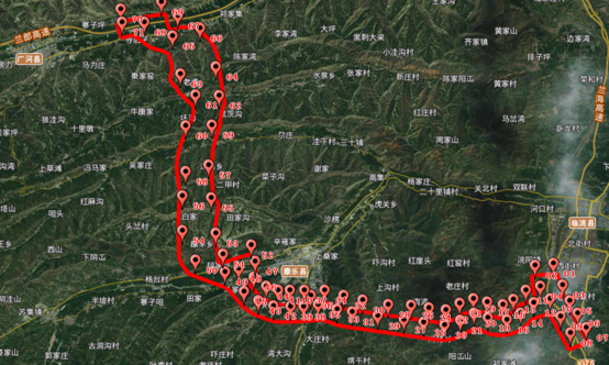

Flight Strategy

Balancing safety and efficiency, our planned flight altitude stands at 40 meters, with a lateral flight distance of 25 meters. Considerations include overhead railway lines, personnel safety, and UAV flight regulations.

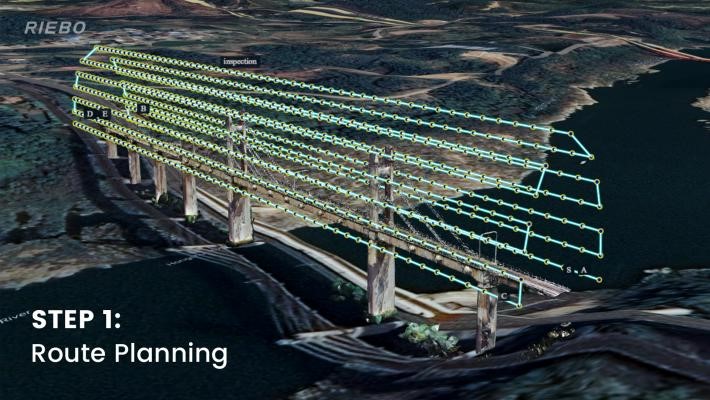

Implementation Process:

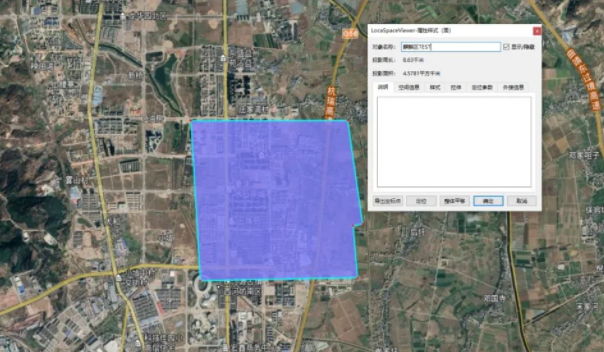

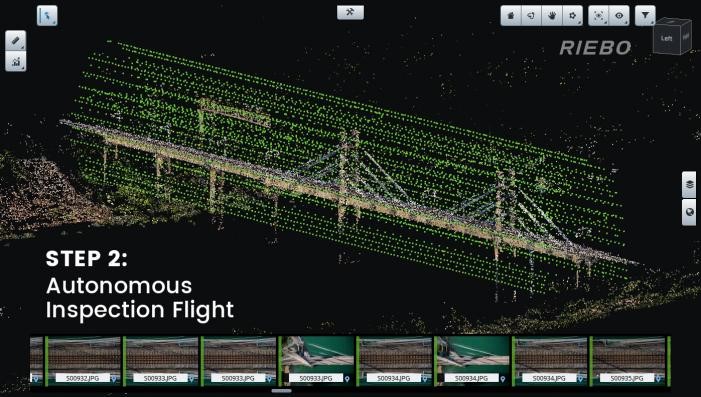

Step 1: Route Planning: 30 mins

Step 2: Autonomous Inspection Flight: 180 mins, capturing approximately 5,000 images

Step 3: Three-Dimensional Reconstruction: 1 day

Step 4: High-Definition Image Hazard Inspection: 2 days

Conclusion

Embrace the future of railway inspections with drone technology. From overcoming challenging terrains to delivering precise data, drones revolutionize safety and efficiency in railway maintenance. Experience the transformative power of UAVs in ensuring the integrity of vital transportation infrastructure.