- 01.Outstanding Aerial Imaging Performance

- 02.High ISO Noise Suppression

- 03.Wide Dynamic Range

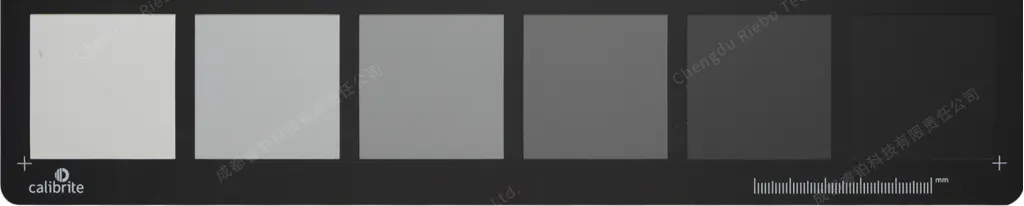

- 04.Precision White Balance

- 05.High-Quality Dynamic Range

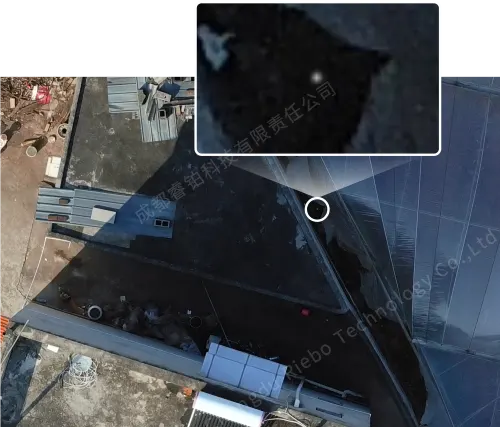

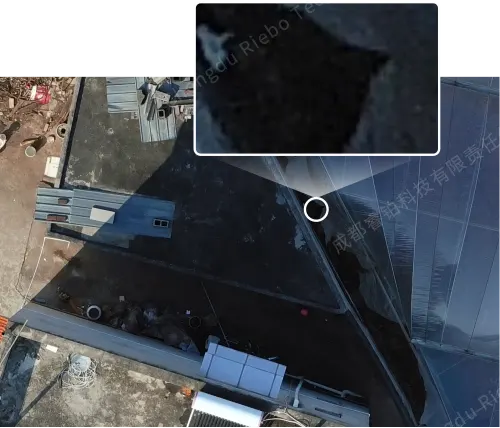

- 06.Defective Pixel Correction

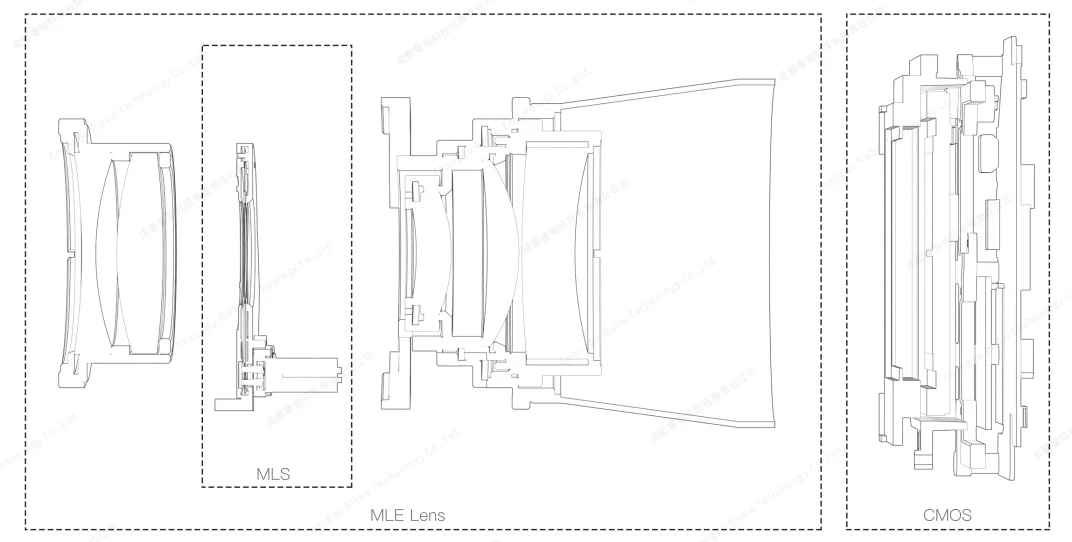

- 07.MLE Lens

- 08.MLS Shutter

- 09.Parallel Type Layout

- 10.Extremely High Synchronization

- 11.Brightness Correction Functions

- 12.Gimbal Function

- 13.Eliminate Redundant Data

- 14.No GCPS Accuracy

- 15.Brand New Image Coding

- 16.Open SDK & Protocol

01OUTSTANDING AERIAL

IMAGING PERFORMANCE

Standard 24-card Photo

Standard 24-card Photo

The quality of the image and white balance determine the final presentation effect of the data. The Riebo camera not only pursues high frame rates and efficiency but also strives for ultimate image quality, possessing excellent image resolution and color reproduction capability.

02HIGH ISO NOISE SUPPRESSION

In aerial photography, high shutter speeds reduce image motion, while increased camera gain ensures correct exposure in low-light scenes. Riebo cameras maintain detail preservation and usability even at ISO 6400. We produce clear, sharp images, meeting project requirements in low-light conditions.

Original Image

Original Image 100%

100% 300%

300%

03WIDE DYNAMIC RANGE

Riebo cameras also boast exceptional dynamic range. In high-contrast scenes, they can preserve details in both highlights and shadows to a greater extent, meeting project requirements in high-contrast scenarios during the summer.

Enlarge highlights details by 200%

Enlarge highlights details by 200% Enlarge shadow

details by 200%

Enlarge shadow

details by 200%

04PRECISION WHITE BALANCE

White balance is the cornerstone of color in aerial surveying, determining the overall effect and authenticity of the photos. With its outstanding white balance capability, Riebo cameras accurately capture the true colors of the real world, allowing each scene to be faithfully reproduced and presenting excellent color performance. It ensures accurate color reproduction even in scenes with large areas covered by monochrome regions, as shown in the image.

Standard 24-color card-Real shot white balance chart

Standard 24-color card-Real shot white balance chart

05HIGH-QUALITY DYNAMIC RANGE

The Riebo aerial camera not only ensures high image clarity but also ensures that edge clarity is as close as possible to the center, ensuring accuracy and quantity in matching identical points.

06DEFECTIVE PIXEL CORRECTION

During the manufacturing process of camera image sensors, bad pixels may arise due to manufacturing defects, affecting the perfection of aerial images. Riebo cameras are equipped with advanced bad pixel correction technology, capable of automatically detecting and repairing bad pixels, providing you with clear and flawless image quality.

Before correction

Before correction After correction

After correction

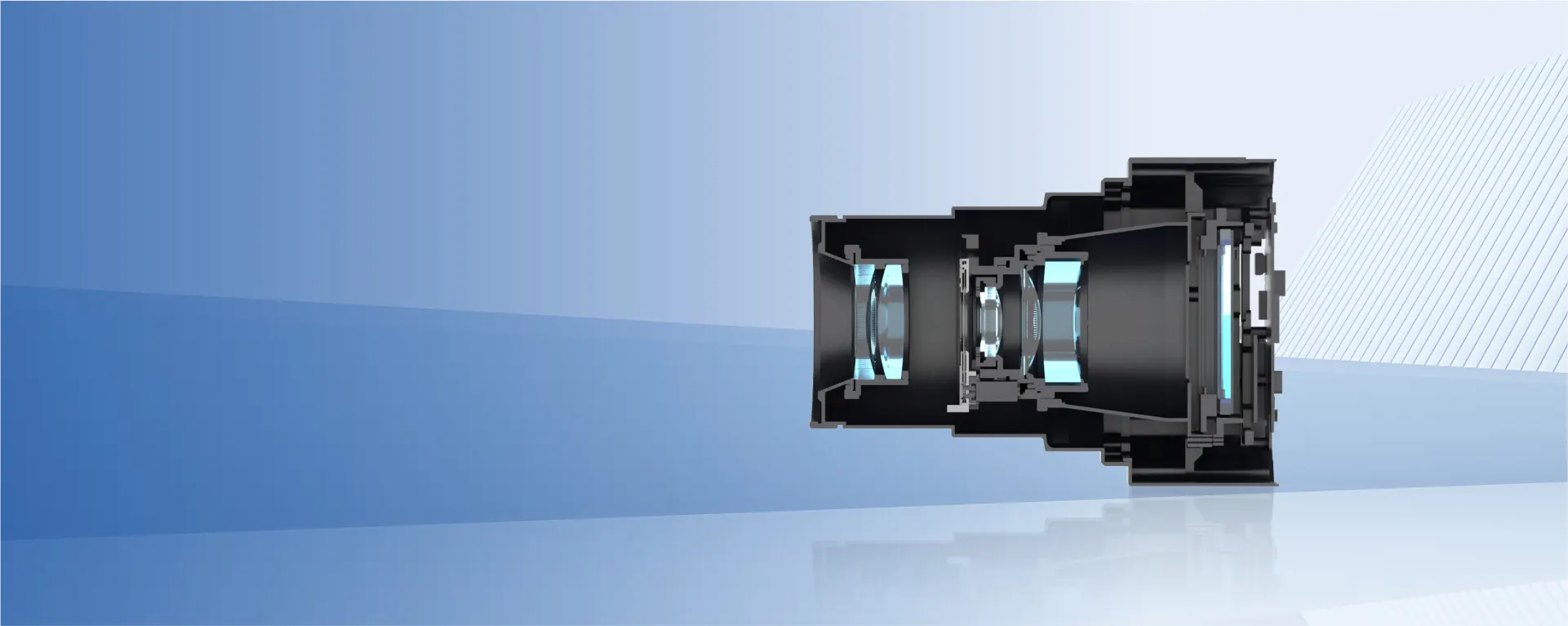

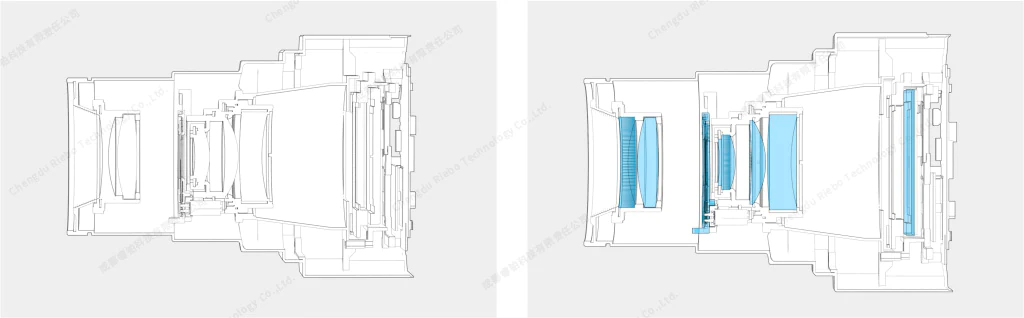

07MLE LENS

As one of the most important devices for camera imaging, the optical lens is the key factor in determining the quality of aerial images.

Distortion will affect the accuracy of the model, spherical aberration wil cause a loss of resolution in the lens, and chromatic aberration wil affect the matching accuracy of Aerotriangulation.

In the case of controlling the lens volume, Riebo high-end oblique camera adopts aspherica lens, at the same time adopts ultra-low dispersion ED lens to correct and eliminate coma-type imaging, effectively control chromatic aberration, and control the lens aberration to within three thousandths.

-

10%~20%Increased number of points

-

20%Reduction of RMS reprojection errors

-

Within3‰Lens distortion control

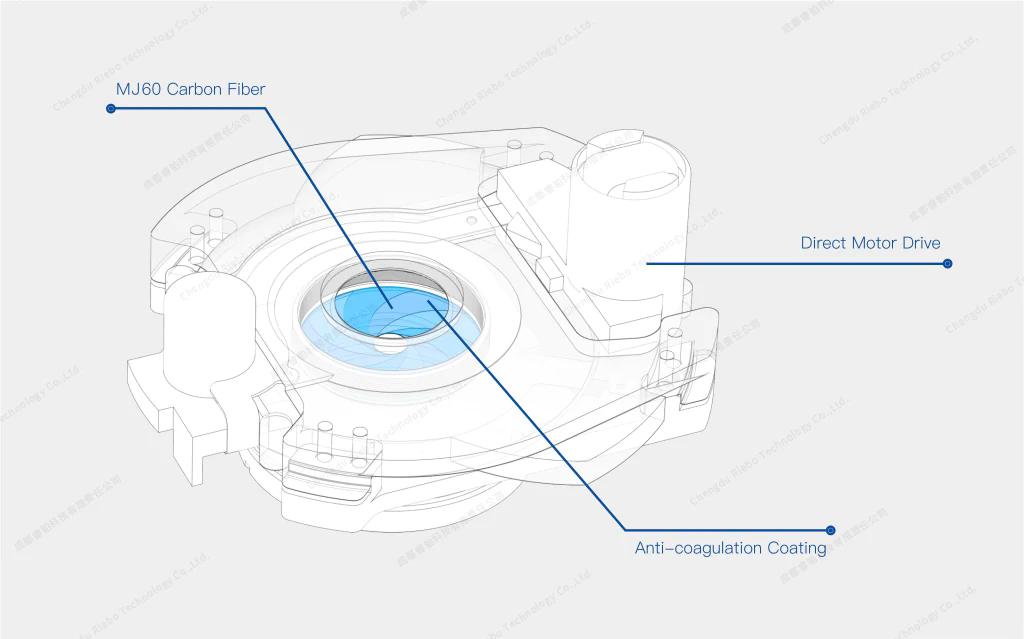

08MLS SHUTTER

Traditional oblique cameras use a mechanical rolling shutter, which will cause motion distortion when shooting. The degree of distortion is related to the camera frame, the larger the camera frame, the greater the distortion. Motion distortion is a fatal problem for aerial survey data collection and can seriously affect model accuracy . It also has some disadvantages, such as short life, low temperature failure and large vibration when taking pictures.

The MLS shutter is the professional shutter developed by Riebo to offer the advantages of light weight, small size, large aperture and no motion distortion.

-

The MLS shutter is made of MJ60 Carbon Fiber, providing a shutter life of 500,000 times even in extreme operating condition.

The MLS shutter is made of MJ60 Carbon Fiber, providing a shutter life of 500,000 times even in extreme operating condition. -

Riebo MLS shutter is coated with anti-coagulation coating, which can effectively solve the problem of shutter condensation in low temperature situation.

Riebo MLS shutter is coated with anti-coagulation coating, which can effectively solve the problem of shutter condensation in low temperature situation. -

The MLS shutter has been tested to work properly at temperatures ranging from -20° to 65°. The direct drive mode of MLS shutter can greatly reduce the vibration and noise of shooting.

The MLS shutter has been tested to work properly at temperatures ranging from -20° to 65°. The direct drive mode of MLS shutter can greatly reduce the vibration and noise of shooting.

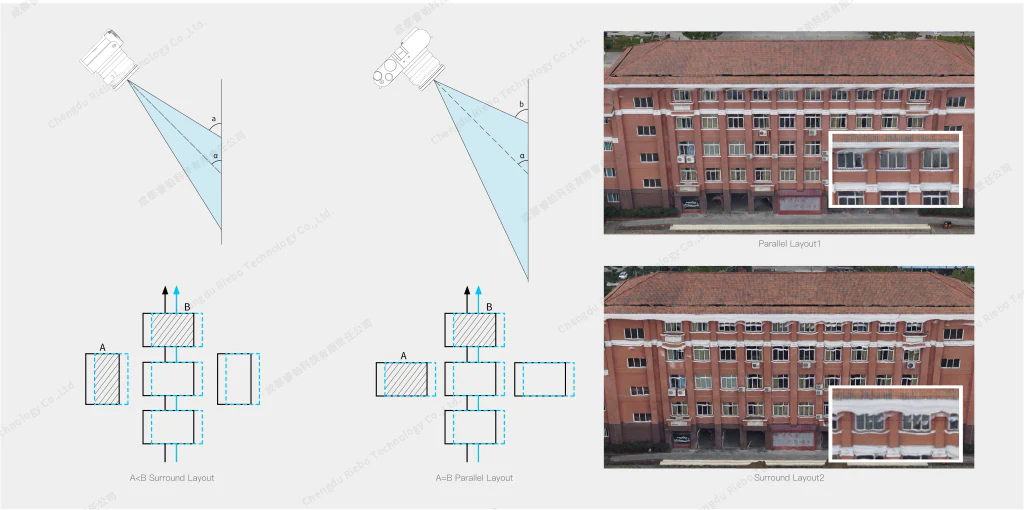

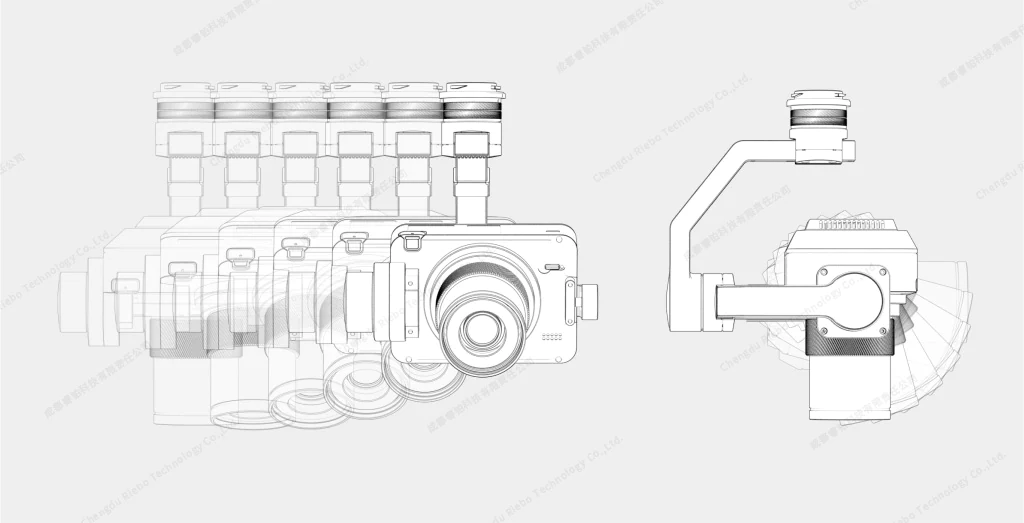

09PARALLEL TYPE LAYOUT

Traditional oblique cameras are built with surrounding layout, which is more compact and reduces camera's weight and size, but also has the following problems:

- The sidelap is lower than the frontal overlap(A< B).

- The surrounding layout has a great influence on the long focal length camera than short or medium focal length cameras. With the same sensor size, the long focal length camera itself will have a smaller field of view (FOV), producing more fuzzy and affecting the modeling effect.

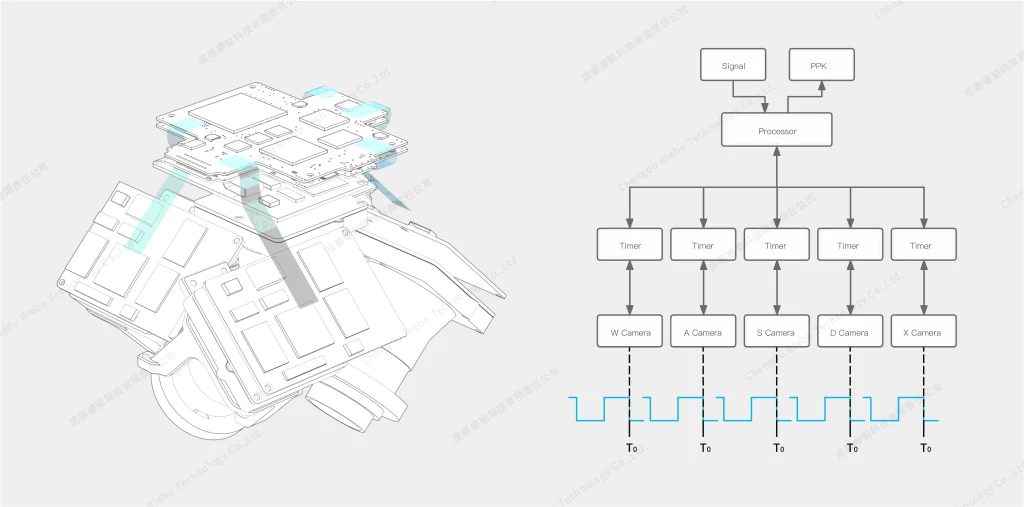

10EXTREMELY HIGH SYNCHRONIZATION

For single lens camera, high synchronization between shutter and differential module is one of the key technologies of high precision aerial survey. In contrast to consumer-grade cameras, the traditional aerial camera synchronization method uses the camera flash hot shoe to synchronize with the differential module which will lead to a difference of at least 1ms.

Riebo has specially developed the technology of synchronization between shutter exposure and differential module, which makes it possible to output the exposure signal to the differential module at any moment during the exposure time of the image sensor, and the synchronization time is less than 50μs.

The five-lens oblique camera must not only ensure high synchronization of individual lenses with the differential module, but also ensure that the five cameras can synchronize to exposure. The key and difficult part of the integration is whether the Lidar's high precision inertial navigation system module can accurately time-stamp the camera exposure time to achieve a high level of integration between Lidar and camera.

The five-lenses oblique camera will take different time to record the photos due to the inconsistencies of the texture. With the accumulation of time and photos, each lens can not output shutter signal accurately, resulting errors.

Riebo has developed the synchronous control technology. Firstly, the crystal oscillator is actively controlled to control the working timing of the five cameras. The feedback compensation method is adopted to control the camera according to the accumulated error of the camera exposure, so as to realize the high-precision synchronization of the five cameras.

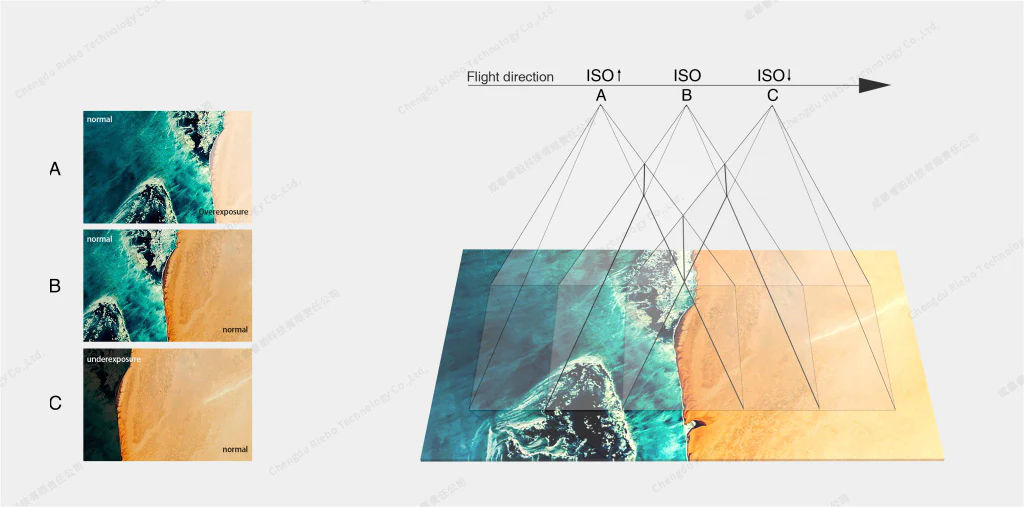

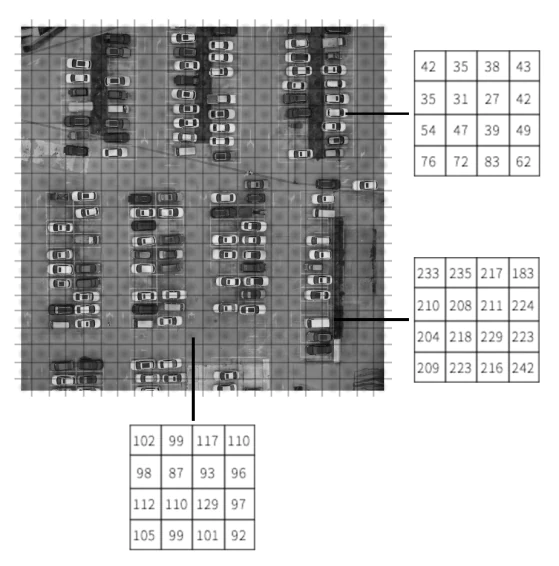

11BRIGHTNESS CORRECTION FUNCTIONS

In oblique photography, the models of light-colored buildings are more prone to have shadow spots. In addition to the change of weather light and shadow during the flight and the software mapping algorithm, inaccurate metering of the camera and chromatic aberration of the five lenses will cause the model to have light and shadow spots. To solve this problem, Riebo high-end oblique camera has a brightness correction feature.

Each lens of Riebo camera will be calibrated before assembly to ensure that tre five lenses do not vary in brightness by more than 30% the same light intensity.

When there is a huge change in the light condition from one frame to the next, the camera considers these changes to be the light and shadow changes, and makes a normal exposure.

12GIMBAL FUNCTION

The oblique camera is fixedly mounted on multi-rotor UAV to follow the drone sloping, resulting in poor camera pose. Meanwhile, the rapid change of drones attitude may lead to fuzzy.

To solve these problems, Riebo has developed a detachable three-axis stabilized gimbal.

The three-axis gimbal not only increases the shooting stability but also expands the oblique camera working mode and application scenarios which can do close-range, advantageous photogrammetry, orbit and other shooting modes

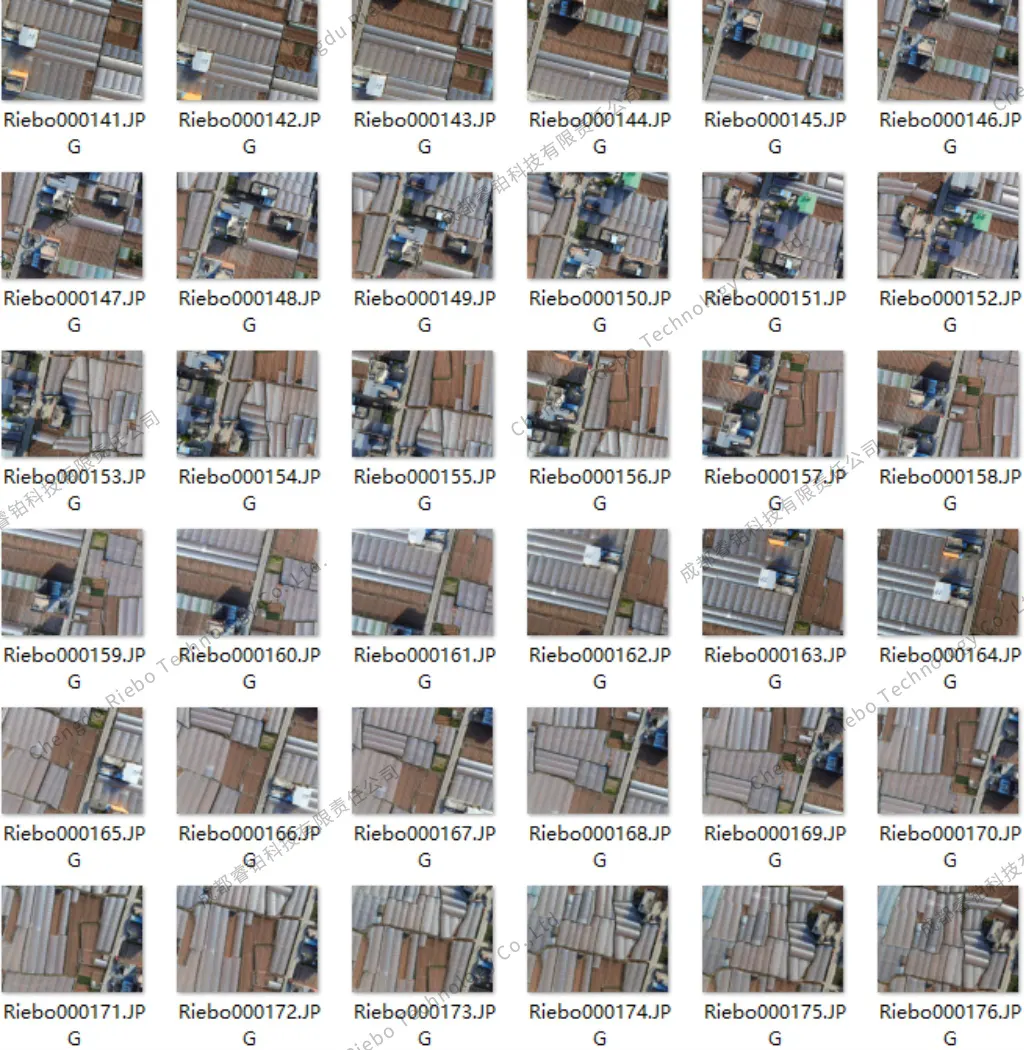

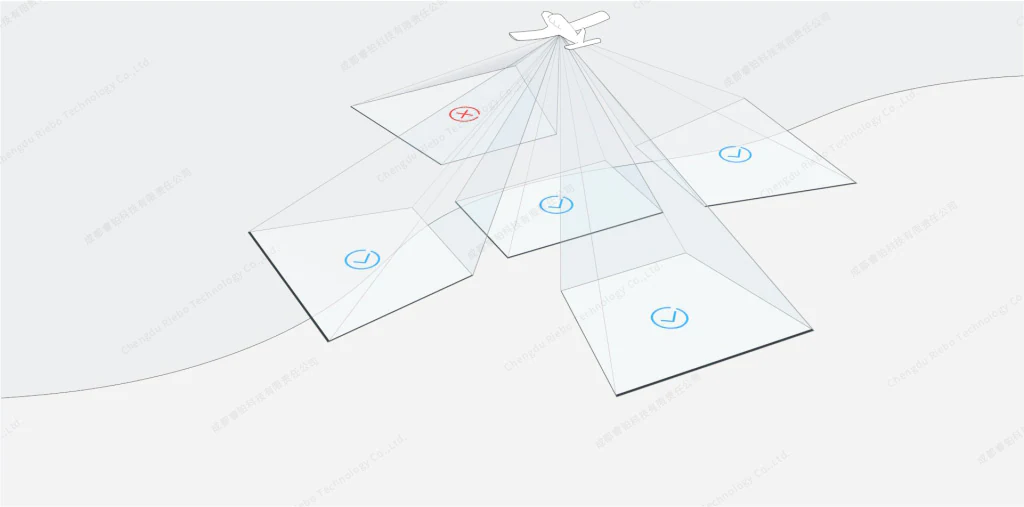

13ELIMINATE REDUNDANT DATA

According to the structural characteristics of oblique camera and the principle of oblique photography technology, the side view camera usually tilts 45°.In the field work, in order to collect the outer side texture information of the edge of survey area, the route planning usually needs to be expanded outward.

The distance of outside expansion L=|Hxtan45°|(H is the flying height). During the flight route expansion, there will be a large number of invalid aerial images which will lead to the increase of the total aerial images and the probability of separate layer in aerotriangulation, seriously reduce the efficiency of data processing.

For this reason, Riebo has developed a data pre-processing software Sky-Filter, which can efficiently and conveniently eliminate invalid aerial images, reduce the number of aerial images by about 30%-60% and increase the data processing efficiency by about 50% while ensuring the accuracy and details.

-

Decrease in total number of photos30%~60%The total number of Images is reduced

-

Increased efficiency in data processing20%Data processing efficiency is improved

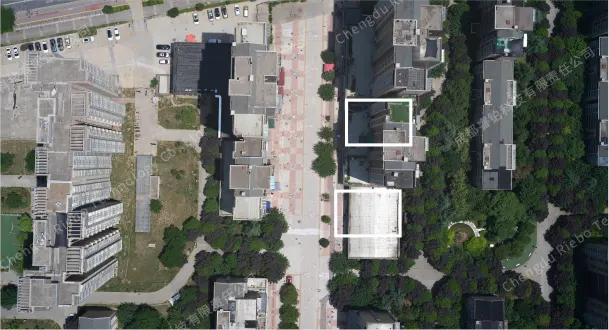

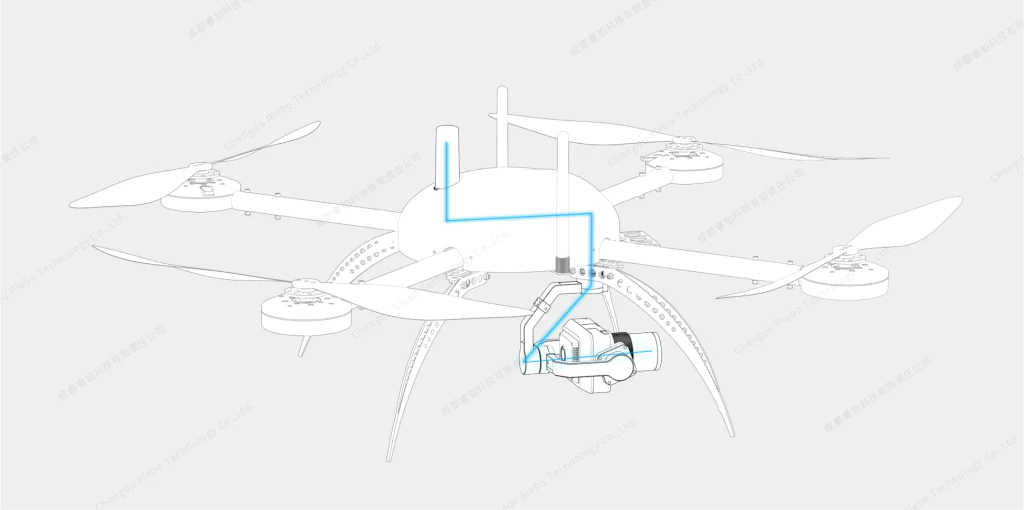

14NO GCPS ACCURACY

To achieve high-precision no GCPs modeling,in addition to controlling optical lens distortion, five-camera exposure and synchronization of PPK/RTK module records, high-precision pos data of each camera is also required.The PPK/RTK module is usually at a certain distance from each camera,and the attitude of the UAV is changing all the time when it is flying, so it is impossible to obtain accurate camera position information directly, which will have a certain impact on the accuracy of no GCPs operation.

Riebo has developed a set of high-precision POS algorithm, which can dynamically and accurately calculate the antenna position of PPK/RTK module of UAV to the CMOS imaging center of each camera.

This algorithm obtain the accurate position information of each camera, and ensure the precision of no GCPs operation.

15BRAND NEW IMAGE CODING

The data block partitioning algorithm and quantization algorithm more suitable for photogrammetric cameras can compress the image size to 50%-70% of the conventional image in the same dynamic range.

The ability to store more images with the same camera storage capacity improves flight efficiency. It can also reduce the amount of internal storage space required for the same number of images, reducing the investment in data processing systems and saving project costs.

For scenarios where data is transmitted over the network, 30%-50% of transmission time can be saved, and bandwidth requirements can be reduced for the same number of images.

16OPEN SDK & PROTOCOL

The camera control SDK is opened to realize the query or setting of camera shutter speed, ISO, white balance, storage space,number of stored photos and other data.

UAV manufacturers can integrate the camera's information module and control module into the ground station. The UAV and camera information can be presented to the user at the same time. improving the user's operational efficiency and experience. solving the problem that traditional aerial survey equipment can only operate independently and cannot do deep integration with the UAVs.