1.Overview of Road Inspection

With the popularity of transportation and the acceleration of urbanization, road construction and maintenance have become indispensable public services in modern cities. According to the statistics of the Ministry of Transport, by the end of 2021, China's highway maintenance mileage exceeded 5.25 million kilometers, accounting for 99.4% of the total highway mileage. This indicates the significant task of road maintenance, where road inspection serves as a fundamental step in identifying and recording road diseases for timely maintenance. In recent years, artificial intelligence technology has been widely applied in this field.

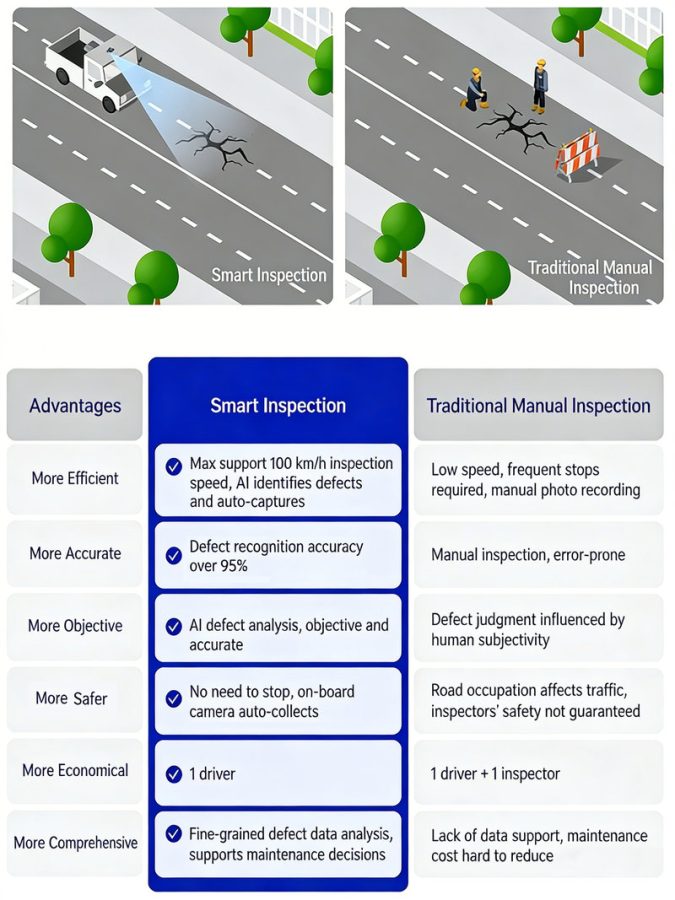

Road maintenance costs are typically 2-3 times the construction costs, and the current manual inspection method in China requires substantial human and material resources, leading to issues such as oversight, low efficiency, and low accuracy. Inspectors also need to stop and take photos for measurements, impacting traffic and lacking safety assurance. Additionally, for management departments, the lack of effective structured data support poses significant challenges to road maintenance decision-making, hindering cost reduction and efficiency improvement efforts.

2.Advantages of the Riebo X3 Road Inspection Plan

(1) Improved Efficiency

The Riebo X3 inspection system can rapidly cover large areas of road surfaces at speeds up to 100 km/h, allowing for quick completion of crack detection tasks compared to manual inspection.

(2) Increased Accuracy

Real-time capture and recording of road surface cracks help avoid subjective errors and oversights. Utilizing image processing and machine learning technologies enables automated analysis and classification of cracks, enhancing detection accuracy and reliability.

(3) Enhanced Safety

Cracks are common road surface diseases that, if not repaired promptly, pose potential risks to traffic safety. Using drones for crack detection allows timely identification and recording of road surface cracks, providing relevant departments with accurate information for maintenance and preservation.

(4) Cost Reduction

Traditional crack detection methods require significant manpower and time, especially for comprehensive inspections of extensive road surfaces, incurring high costs. Using drones for crack inspection reduces operational costs, improves detection efficiency and accuracy, thereby lowering maintenance and preservation costs for relevant departments.

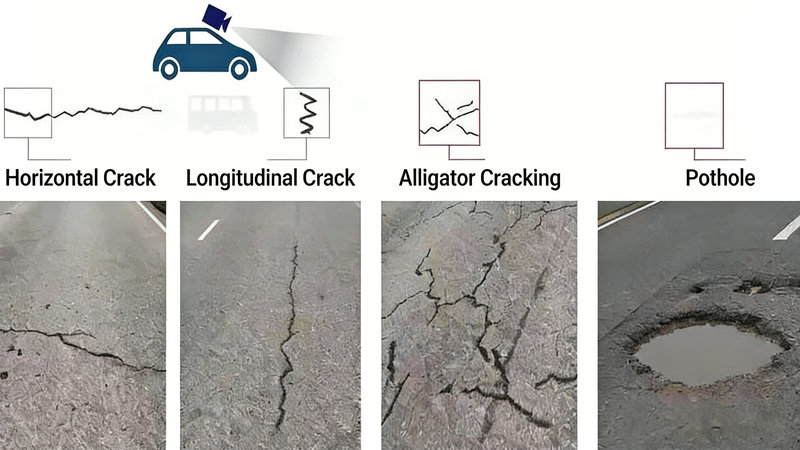

3.High-Precision Crack Identification

There are various types of road diseases, such as cracks, undulations, fractures, etc., which can be identified through high-precision algorithms. Currently, deep learning algorithms for image recognition are mature, and the Riebo X3 inspection plan incorporates specialized small-model algorithms for intelligent inspection, achieving an accuracy rate of over 95% and automatic classification of different types of road diseases.

The road disease algorithm recognition inspection system is based on deep learning algorithms trained on images of road crack diseases, enabling the identification, segmentation, and counting of road cracks.

4.AI Enhancement for Effective Road Inspection

Based on the practical application results of multiple projects, the Riebo X3 road intelligent inspection system can increase post-inspection efficiency by more than 4 times compared to manual inspection. Simultaneously, by reducing personnel and material inputs, road maintenance costs can be reduced by 50%. Visualizing multi-dimensional disease information assists in maintenance business decision-making, increasing decision efficiency by 200%.

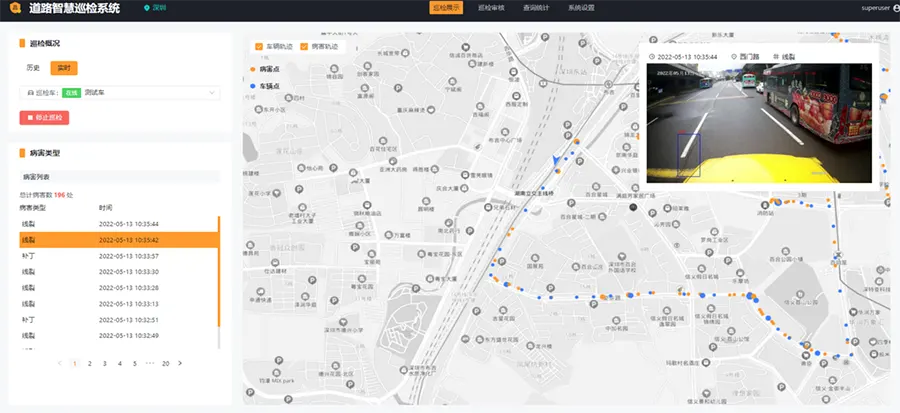

5.Inspection Data Management

Currently, most inspection operations result in inspection reports, which lack intuitive presentation, making it difficult to reuse inspection outcomes, supervise the inspection process, and face issues such as low integration and non-universal data outcomes in existing inspection software.

To address this, Riebo Technology has developed the Tongtu Smart Inspection Management System, which digitizes the entire inspection process, integrating functions such as personnel management, data management, disease identification, disease location, 3D visualization of diseases, historical disease comparisons, data statistical analysis, and customized inspection report outputs.