Industry Background

At present, the third energy revolution is gradually shifting the global energy structure towards renewable energy sources. Solar energy, as a clean energy source with significant potential, is receiving increasing attention.

Photovoltaic panels are devices that utilize the principles of photovoltaic conversion to directly or indirectly convert solar radiation into electrical energy.

During the use of photovoltaic cells, structural defects such as microcracks, grid breaks, contamination, or cell degradation may occur, which can potentially impact the power and efficiency of solar modules.

Traditional imaging systems find it challenging to identify these defect issues. It is necessary to use Electroluminescence (EL) to detect defects in solar cells such as hidden cracks, ghost images, dark spots, ribbon marks, diffusion anomalies, and other defects.

Program Overview

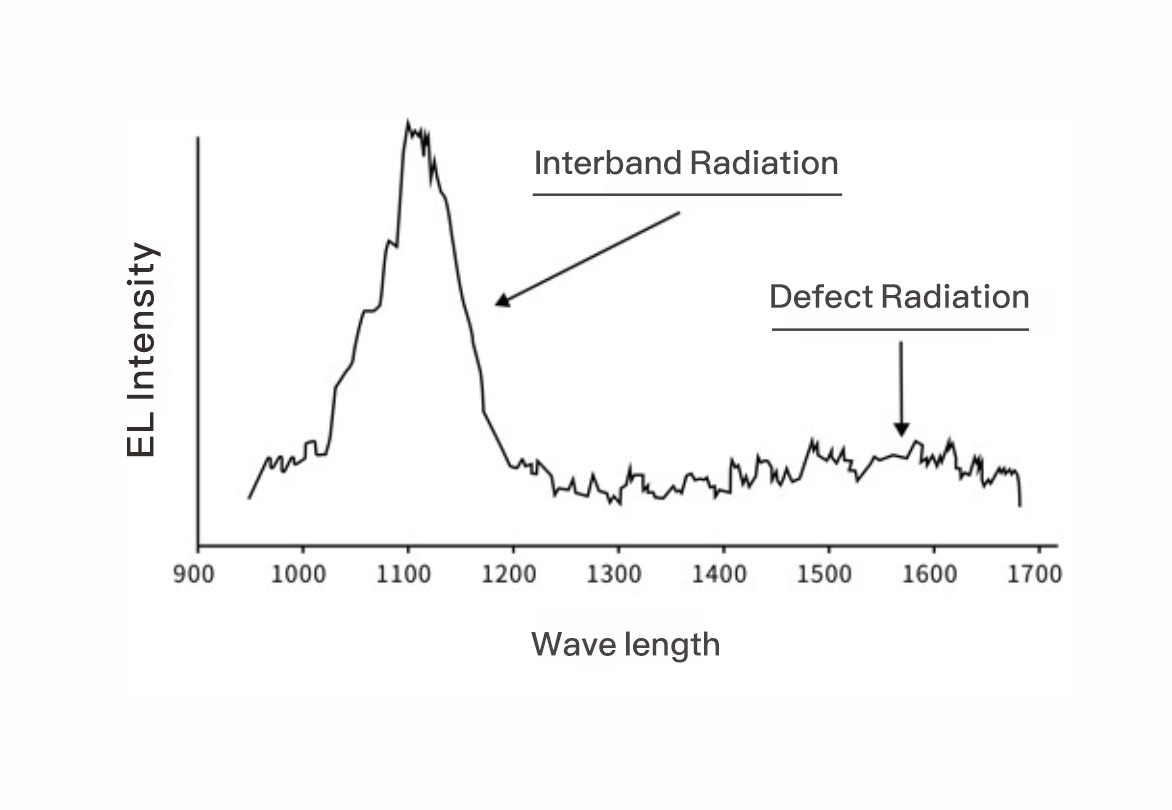

Electroluminescence (EL) is the phenomenon of converting electrical energy into light energy by applying voltage to a material, resulting in inter-band radiative recombination.

For silicon materials, the luminescence spectrum peaks at 1110nm, with an inter-band recombination width ranging from 1000 to 1300nm.

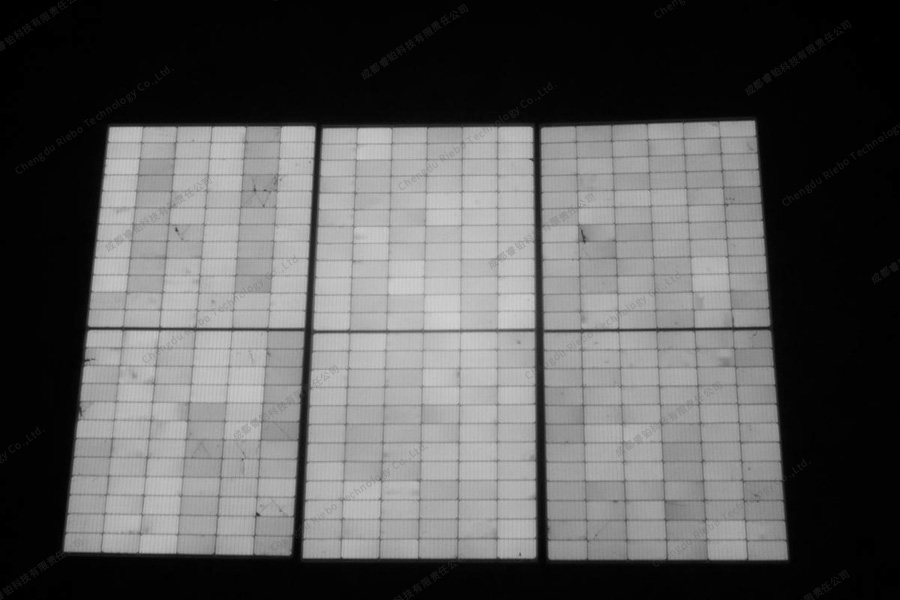

In acquired images, a normally functioning solar cell exhibits high brightness and relatively uniform brightness distribution in the conductive active region.

In contrast, inactive and poorly connected regions appear dim.

Due to the extremely weak nature of EL in solar cells, high-sensitivity EL cameras are essential for photovoltaic inspections.

Riebo EL Inspection Solution

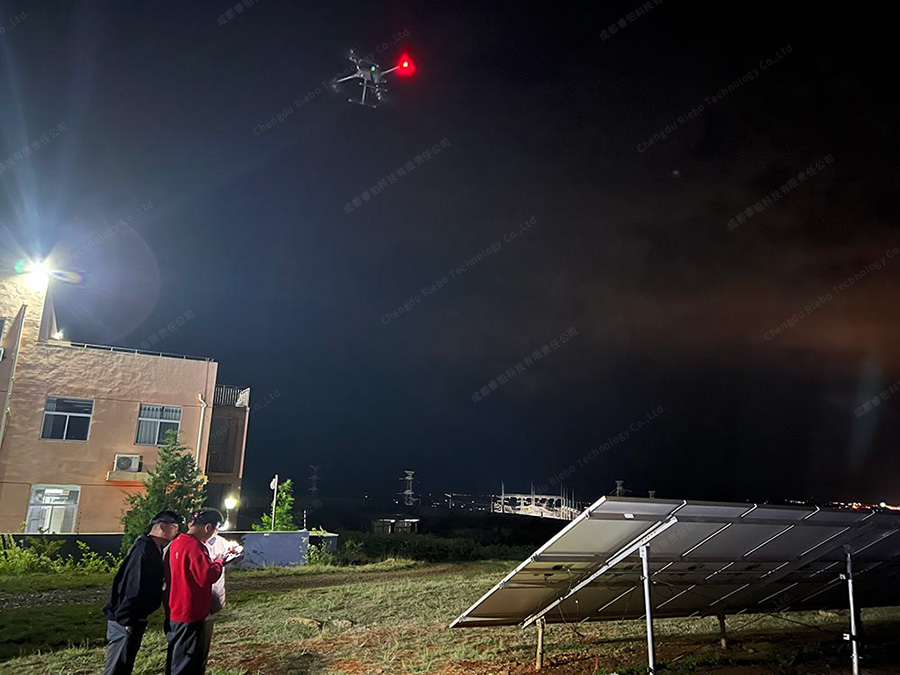

The Riebo EL Inspection System is based on the DJI drone platform, providing fast and accurate component detail resolution, ensuring the safety and reliability of photovoltaic power station.

Inspection Industry Development Trend

EL inspection of components at the power station is a commonly used method, frequently applied in scenarios such as power plant delivery, acceptance, due diligence, abnormal power generation, and post-natural disaster claims.

Traditional inspection methods using portable equipment suffer from low efficiency, high costs, and significant safety risks for personnel. EL inspection of power plant-side components has remained at a low level, with many power plants operating with latent issues.

In addition, some special power plants, such as those on water surfaces, in greenhouses, or in building-integrated photovoltaic systems (BIPV), face geographical and spatial limitations, making manual operations highly challenging.

The Riebo drone-based EL inspection solution is flexible and precise, capable of meeting the inspection needs of various types of power plants, while significantly improving inspection efficiency.