Challenges and Risks of Suspension Bridges

With their exceptional spanning capacity, suspension bridges play an irreplaceable role in the construction of long- and ultra-long-span bridges. To date, there are over 30 suspension bridges worldwide with a main span exceeding 1,000 meters, more than 15 of which are in China—making the country the global leader in kilometer-class suspension bridge ownership.

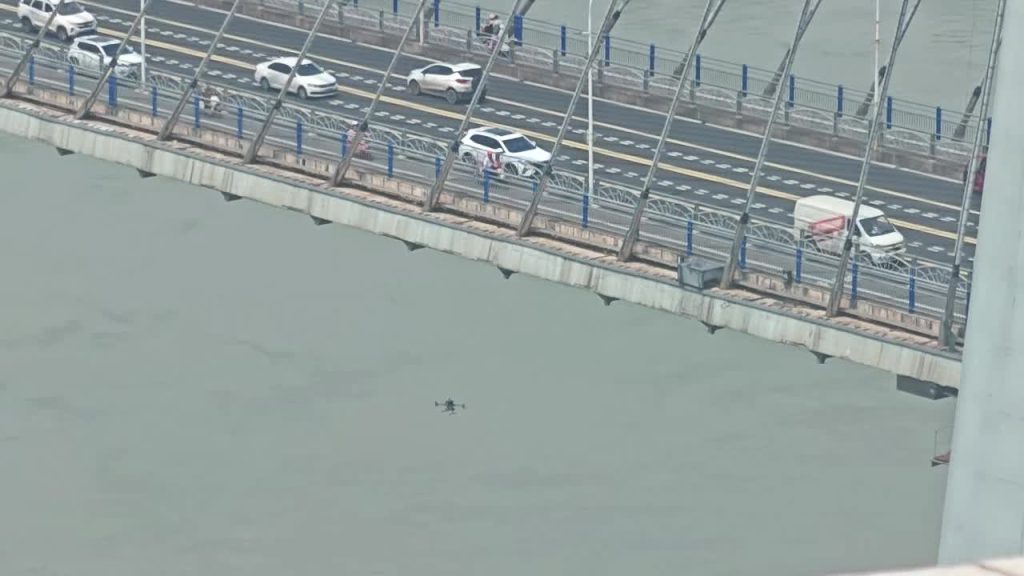

△cable-stayed bridge nspection

△cable-stayed bridge nspection

However, these mega-projects face multiple structural risks under the combined influence of environmental exposure and traffic loads. If the PE coating on main cables becomes damaged or cracked, moisture intrusion can quickly cause corrosion of internal steel wires. Hangers are vulnerable to broken wires or sudden failures due to the combined effects of fatigue loading and environmental corrosion. Concrete components such as anchorages and towers may develop cracks, honeycombing, and spalling. If these early-stage defects are not promptly addressed, they can trigger chain reactions, seriously threatening structural safety and operational stability.

From Manual Inspection to Intelligent Monitoring: Towards a Modernized Maintenance System

Today, suspension bridge maintenance has evolved into an integrated technical framework combining regular inspections, preventive maintenance, and intelligent monitoring, greatly improving efficiency and precision. Drone inspection, as a core element of the intelligent monitoring system, has become the key to breaking the limitations of traditional methods with its high efficiency, flexibility, and broad coverage.

In addition, technologies such as fiber-optic cable force monitoring and cable-climbing robots work in synergy, creating a multi-technology, multi-dimensional modern maintenance solution that provides comprehensive protection for bridge safety across its entire lifecycle.

Drone Inspection: A Digital Safeguard for Bridge Health

1. Precision Coverage, Detailed Insights

Drones can easily reach high and hazardous areas such as main cables, hangers, and saddles. Equipped with high-definition imaging devices, they capture millimeter-level imagery, effectively overcoming the reach and visibility limitations of manual inspection and significantly improving defect detection coverage and accuracy in critical structural components.

2. High Efficiency, Flexible Deployment

Without the need for scaffolding or other auxiliary facilities, drone inspections can be deployed rapidly, ideal for routine high-frequency patrols and emergency inspections. They dramatically shorten preparation time and emergency response cycles.

3. Reliable Data, Easy Archiving and Tracking

Drone-collected inspection data can be stored in a structured, standardized format, providing traceable quantitative evidence for health assessments and defect trend tracking. This supports the creation and continuous updating of bridge health archives.

Inspection Depth Classification: Five-Tier System

According to national bridge maintenance standards, inspection work is divided into five levels of technical depth and risk response:

Level I: Remote visual inspection.

Levels II–III: Close visual inspection (within 50 cm of the target).

Level IV: Assisted inspection using touch, hammer tapping, or optical magnification.

Level V: Comprehensive inspection using drones, structural health monitoring systems, and load testing.

With its high-definition imaging, zoom capabilities, and 3D modeling, drone inspection can meet a wide range of Level I–IV needs. When equipped with LiDAR, infrared thermography, or other sensors, drones can also assist in Level V deep inspection tasks. This makes UAVs an essential tool for meeting the high-precision, complex-environment demands of suspension bridge maintenance.

Digital Twins and Intelligent Monitoring: Building the Future of Bridge Maintenance

As modern integrated transportation planning advances, suspension bridge maintenance is shifting toward a full-lifecycle proactive control model. By integrating BIM (Building Information Modeling) with digital twin technology, the industry is making a leap from reactive repair to predictive intelligence, creating a closed-loop management system for smart alerts, condition forecasting, and maintenance planning.

High-resolution images and structured data collected by drones serve as core inputs for digital twin models, providing the foundation for dynamic, visual digital representations of bridges. This enables real-time simulation of bridge conditions and full-lifecycle digital management.

Conclusion

Drone inspection technology is ushering suspension bridge maintenance into a new era of intelligence and digitalization. With its efficiency, comprehensiveness, and precision, it has become a core tool for ensuring structural safety and extending service life. In the future, as digital twin and other cutting-edge technologies become more deeply integrated, drones will play an even greater role in the bridge maintenance ecosystem, continuously enabling the safe operation of these mega-engineering marvels.

If you’re looking for a more efficient and safer way to inspect bridges, RIEBO Technology’s drone bridge inspection solution offers a complete end-to-end service—from data acquisition and AI-powered defect detection to digital twin management. Our system can perform high-precision inspections of critical components such as main cables, hangers, and towers without disrupting traffic, delivering intuitive 3D visualization results.

Contact us today to bring your bridge maintenance into a new era of digitalization and intelligence.