-

Riebo Inspect Master

-

AI Platform

-

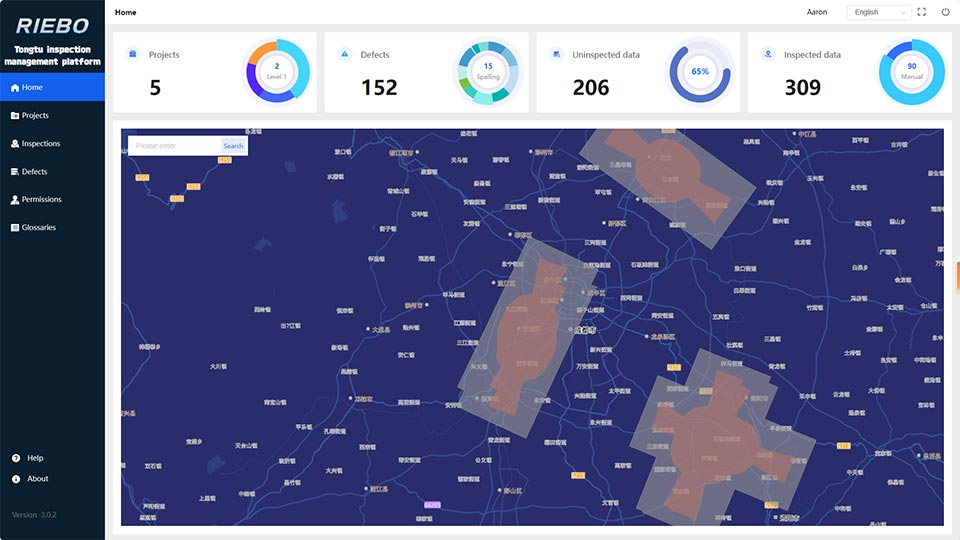

Riebo Inspect MasterOperating environment: Supports Windows 7 and above 64-bit operating systems, with a minimum display resolution of 1080×720p.

The current inspection plan has the following three significant problems: lack of digital management, low reusability of inspection results, difficulty in supervisory checks during the inspection process; the software platform also faces issues of low integration and non-standardized data interchange.

To address these challenges, Riebo Technology has developed the 'Riebo Inspect Master' Intelligent Inspection Management Platform. This system digitizes the entire inspection process, integrating functions such as personnel management, data management, defect identification, defect localization, 3D visualization of defects, historical defect comparisons, data analysis, and customizable inspection report generation.

Data processing is facilitated by the Skyscanner software, which is compatible with Riebo's full range of cameras. This software allows for the export of inspection data by flights or batches, effectively managing a huge amount of inspection data.

Furthermore, the software can write GEO information (including orientation and position) into photos, enabling high-precision coordinate correction. According to the drone and camera's posture information, the software calculates the image's field of view that providing data support for accurate defect localization in subsequent stages.

For WindowsDownload

-

AI PlatformOperating environment: Supports Windows 7 and above 64-bit operating systems, with a minimum display resolution of 1080×720p.

With advancements in image recognition algorithms based on convolutional neural networks and deep learning, the application of artificial intelligence for defect identification using high-resolution inspection images has become more accessible and mature. The specific workflow is as follows:

Step One: Mark collected image data and provide it to the convolutional neural network model for training. The trained neural network model can rapidly detect cracks in images. The recognition rate of the model can be collectively improved through refining the model and gathering more training data.

Step Two: For images in which defects have been identified, a series of processes including enhancement, noise reduction, image segmentation, and edge detection are conducted to obtain results of crack segmentation and measurements at the pixel level.

Utilizing optimization segmentation algorithms based on deep learning, the crack pixel-level overlap rate is high. The algorithm can provide accurate segmentation results even in cases of small cracks, complex backgrounds, and interference from human markings.

Meanwhile, other defects in bridges, such as cracks in steel structural welds, corrosion, loose bolts, and voids, are also identified.

For WindowsDownload