The safety of navigation along the Yangtze River is vital to both public welfare and economic development. As a result, the annual survey of unstable cliff rock masses on both banks has become a top priority for local land authorities. Traditionally, surveyors had to descend by ropes to approach and inspect rock masses manually—an operation of extreme difficulty and life-threatening risk.

In August 2023, this long-standing challenge finally saw a breakthrough. Riebo Technology, with its M6Pros close-range photogrammetry camera, collaborated with the team of Academician Zhang Zuxun, a leading authority in China’s photogrammetry field, to conduct an on-site survey of the Jianchuandong hazardous rock mass on the left bank of the Wuxia Gorge in the Three Gorges Reservoir area. Leveraging drone-based close-range photogrammetry, the project marked a new model for high-precision rock mass monitoring.

A Critical Area of Geological Risk

Academician Zhang Zuxun is a pioneering figure in China’s photogrammetry and remote sensing discipline, widely recognized for his contributions to advancing digital photogrammetry and promoting its international development.

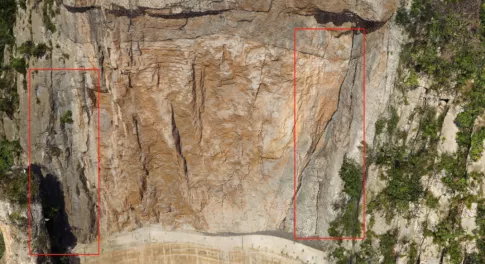

The Jianchuandong rock mass is primarily composed of argillaceous striped limestone, which has undergone severe deterioration under the influence of fluctuating reservoir water levels. The base shows signs of cracking, slippage, and potential toppling failure. More critically, this rock mass lies within the Goddess Peak Scenic Area, directly above a busy navigation channel with heavy vessel traffic. Any collapse would pose an immediate threat to navigation safety—making precise monitoring and reliable data support for risk mitigation the central goal of this project.

Facing Multiple Challenges: Complex Terrain and Stringent Accuracy Requirements

1. Difficult Working Environment

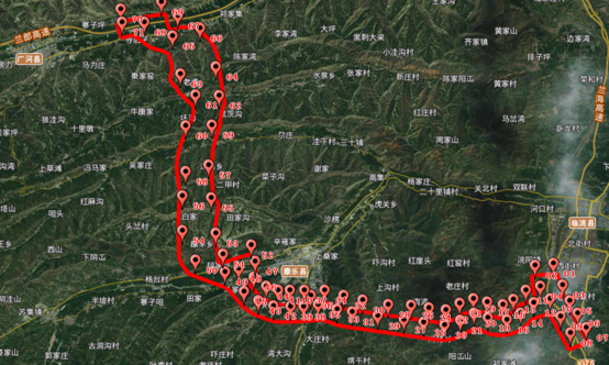

The survey site is located in Wushan County, Chongqing, an area of steep terrain and limited accessibility. The team had to travel by boat, as no roads could accommodate equipment transport. Upon arrival, finding a suitable take-off point became another obstacle.

Launching directly from the boat proved infeasible due to strong waves from passing cargo ships, which caused the vessel to rock violently. The team ultimately chose to take off from the opposite riverbank, 400 meters away—also a steep slope—requiring members to carry all equipment uphill on foot. Additionally, the area’s frequent strong winds meant the drone had to be manually caught during landing, further increasing the operational risk.

2. High-Precision Data Requirements

The project’s core task was to detect rock crack widths and changes between two measurement intervals, which demanded extremely high data accuracy.

The rock face’s irregular geometry and dense surrounding vegetation required the drone to maintain a safe distance to prevent collision, yet it also needed to capture fine crack details for high-resolution modeling. Balancing safety distance and image clarity placed stringent requirements on the camera’s focal length, sensor size, stabilization performance, and the drone’s wind resistance.

Technical Breakthrough: M6Pros and System Integration

1. Core Equipment: Precision Meets Stability

The team used a DJI M300 RTK drone as the carrier platform, renowned for its wind resistance and flight stability in Class 3–4 winds. Mounted beneath was the Riebo M6Pros close-range photogrammetry camera, the key to the mission’s success.

Equipped with a three-axis stabilized gimbal, the M6Pros effectively reduced flight vibration and maintained a 5 mm ground sampling distance (GSD) even at 50 meters away—balancing safety and precision. Its versatility allowed the same system to capture orthophotos, build high-detail 3D models, and execute automated waypoint missions through DJI Pilot, with real-time parameter adjustment, live preview, and remote control of recording—all ensuring operational efficiency and control.

2. Flight Route Planning: Software-Driven Accuracy

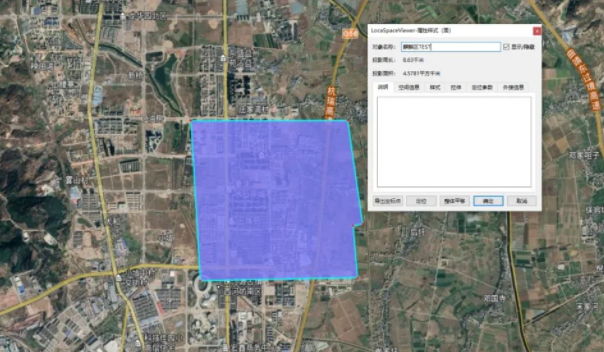

To adapt to the area’s complex topography, the team used Waypoint Master software for flight planning. The software supports multiple flight modes—such as orbit, terrain-following, and façade mapping—enabling flexible configuration based on survey conditions.

For the uneven rock surface and partially obstructed areas, Waypoint Master dynamically adjusted flight distances to maintain uniform image resolution. Following standard overlap settings (80% forward / 70% side), the team completed data acquisition in just 1.5 sorties, collecting 300 high-quality, evenly colored images, fully meeting project specifications.

Results: High-Resolution 3D Model Enhances Safety Monitoring

The outcomes of the survey validated the robustness of the technical solution.

- Efficiency: The M6Pros achieved 5 mm resolution at 50 m distance, covering 0.1 km² in just 1.5 flights with 300 photos—significantly improving field productivity.

- Model Quality: Leveraging Riebo’s years of photogrammetry experience, the M6Pros maintained consistent imaging parameters across diverse environments. Its 35.7 × 23.8 mm CMOS sensor—7.3 times larger than that of the Phantom 4 RTK—provided greater dynamic range and light sensitivity, enabling richer texture capture and more detailed 3D reconstruction.

The resulting high-fidelity 3D reality model vividly represented the rock’s surface conditions, offering accurate, data-driven support for rock stability assessment and hazard mitigation planning.

A Milestone in Drone-Based Cliff Surveying

This collaboration between Academician Zhang Zuxun’s team and Riebo Technology stands as a landmark case for the mature application of drone close-range photogrammetry in hazardous rock mass surveying.

As technology continues to evolve, such safe, efficient, and precise approaches will play an increasingly vital role in geological monitoring and infrastructure safety management, contributing to the long-term protection of the Yangtze River navigation channel and beyond.