In the field of highway design and construction, high-precision topographic data and 3D real-scene models are the core foundations for ensuring scientific planning and efficient advancement of projects. With the advantage of rapidly acquiring three-dimensional geographic information, oblique photography technology has become a key technical means in modern highway survey and design. Taking the S36 Lintao-Kangle-Guanghe Expressway project as an example, this article elaborates on the specific application of surveying cameras in highway design in complex terrain, demonstrating their significant value in improving data accuracy, optimizing operation processes, and supporting engineering decision-making.

Project Background

The S36 Lintao-Kangle-Guanghe Expressway is one of the key highway construction projects in Gansu Province during the "13th Five-Year Plan" period. It is also an important channel connecting Linxia, Gannan ethnic minority areas and the southwest region in Gansu Province, playing a crucial strategic role in the national and Gansu provincial trunk highway networks.

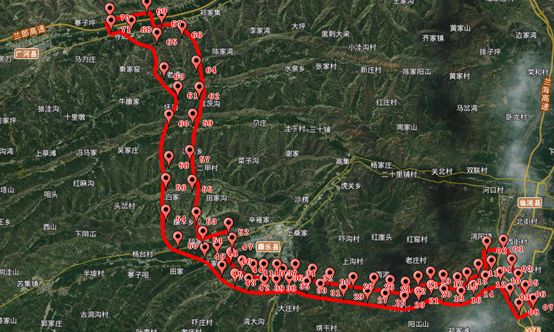

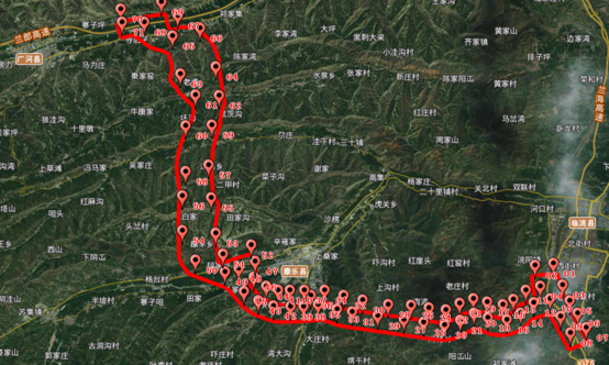

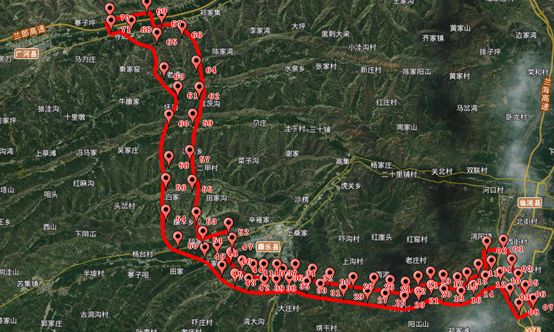

The main line of the project starts at Gaojiabao, Taoyang Town, Lintao County, connecting with the G75 National Expressway via a hub interchange. It passes through Zhangjiaping, Suanciwan, Wangjia Village, Kangle County Town, Liuchuan Township, Dibaping, and Sihouzi Village, and ends at Caiwangjia, east of Guanghe County Town, connecting with the G1816 National Expressway via a hub interchange. The proposed project is located between 103°37′01″E to 103°51′19″E and 35°20′00″N to 35°29′48″N.

Overview of the Survey Area

The survey area of this project is located in Gansu Province. The terrain is steep with a height difference of more than 100 meters. The area is mostly covered with low-rise and dense houses of 2-4 floors, all less than 20 meters in height. The features include farmland, grassland, etc., which are typical.

The UAV operation was carried out from 10:00 to 15:00 on June 20-23, 2020. During this period, the weather in the survey area was sunny with moderate light and a 1-2 level breeze, which was suitable for flying.

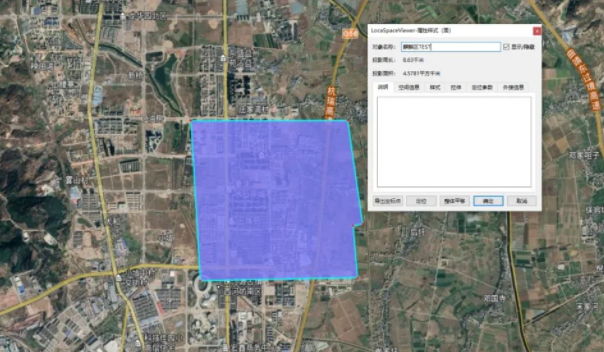

The area of the survey region is 55.6 square kilometers. A total of 35 ground checkpoints and 71 image control points were set up, with clear and easily identifiable positions to meet the project production needs.

Equipment Selection

The main equipment used for the aerial survey of the project is a vertical take-off and landing fixed-wing UAV equipped with the Raybot DG4pro, and Trimble RTK was used for the measurement of image control points and checkpoints.

The Raybot

DG4 Pros oblique camera has many advantages. Its focal length is longer than that of ordinary oblique cameras on the market, which can not only ensure that the UAV flies at a sufficiently safe height but also ensure that the resolution of ground objects reaches within 4.5 centimeters. At the same time, the full-frame lens can help capture more angles of ground objects during flight, thereby improving the model quality as much as possible. The specific parameters of the camera are as follows:

- Dimension: 145*145*114mm

- Weight: 960g

- Total camera pixels: 225 million

- CMOS size: 36*24mm

- Power supply: Unified power supply by UAV

- Camera exposure mode: Equal time / equal distance

- Focal length: Orthophoto 40mm, oblique 56mm

- Data copying method: Unified external memory

- Tilt angle: 45°

- Minimum exposure time: 0.6s

- Data copying speed: 300Mb/s

- Lens arrangement: Parallel layout

Aerial Flight Overview

Pre-operation Preparation

Check the status of UAV, camera, GPS and other equipment to ensure they are airworthy, complete the relevant airspace approval for the aerial flight operation, conduct on-site survey combined with existing data and satellite images to determine the best UAV take-off and landing site, and complete the layout of image control points.

Route Layout and Aerial Survey

In this project, the designed flight height is 350 meters, the ground sampling distance (GSD) is 4.5cm, and the effective area of the survey area is about 55.6km². According to the distance of expanding the flight height by one time, the actual aerial flight area is about 70.2km². In accordance with the requirements of conventional topographic map measurement, the project was operated with a course overlap of 80% and a side overlap of 70%, with a total of 8 sorties. The flight time of a single sortie is about 42 minutes, and a total of 27,800 images were obtained. All images are clear and uniform in color, which can meet the requirements of this project.

Data Processing Results

Aerial Triangulation Calculation

Traditional RTK technology needs to transmit data through data links, which is easily affected by environmental factors. Especially in areas with complex terrain such as mountainous areas and forest areas, due to the limitation of radio technology, RTK technology is difficult to play its advantages. However, PPK technology, as a dynamic relative positioning technology using carrier phase observations for post-data processing, does not require data communication, has a large effective operation radius, and can obtain static data through the base station and dynamic data from the aircraft end to calculate high-precision POS data, which greatly improves work efficiency.

This project uses CONTEXT CAPTURE software with 17 nodes, and the workstation is configured with Intel i9-9700EX, 128G memory, and 1080ti graphics card.

The Raybot DG4PRO camera took a total of 27,800 photos. After filtering out 4,170 aerial photos, 23,630 remained. The scanner preprocessed XML files can be directly imported into the CONTEXT CAPTURE modeling software. After image dense matching, dense point cloud construction of triangular networks, white film generation and texture mapping, the real-scene 3D modeling is completed.

This project processed the aerial photos in three parts. One part has 8,800 aerial photos, and the aerial triangulation took a total of 2 hours and 49 minutes, with 100*100 tiles. It took about 20 hours to complete all modeling.

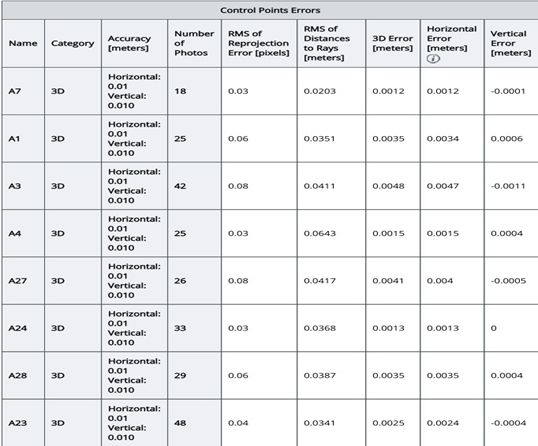

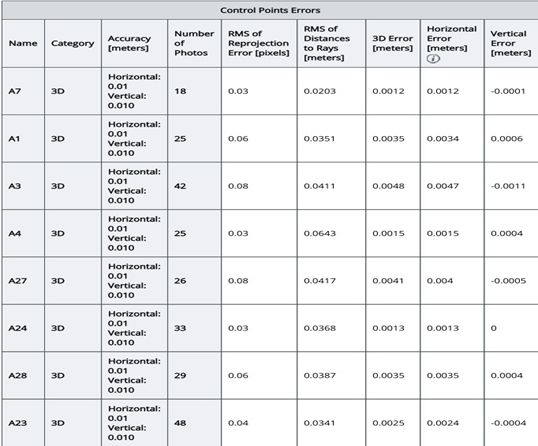

Partial results of the block adjustment are as follows:

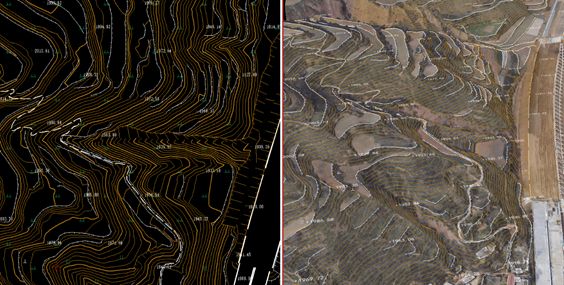

DLG and DTM Drawing

The real-scene model (OSGB format) is loaded into Shanwei Tsinghua EPS software for stereo collection, and the 1:2000 scale digital line graph and digital terrain model are drawn.

Project Conclusion

Verified by field measured points, the topographic map results of this project have excellent accuracy: the plane coordinate mean error is better than 10cm, and the plane coordinate mean error in special terrains such as densely vegetated areas and alpine regions is better than 20cm; the elevation mean error is better than 10cm. The quality of the topographic map is excellent, and the data results have high accuracy, meeting the requirements of the "Highway Survey Specification" and "Highway Survey Detailed Rules".

Application of Results

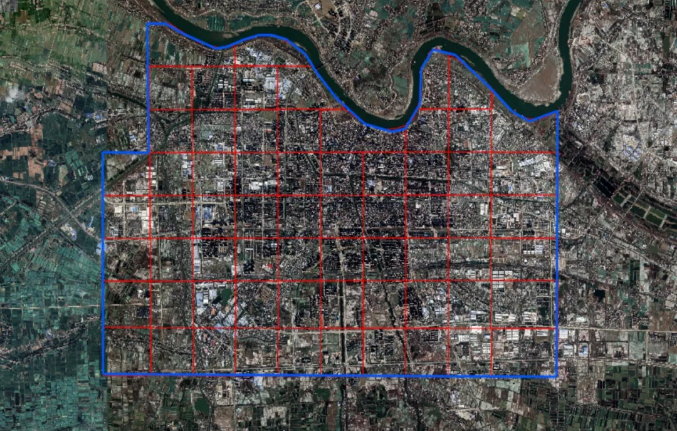

Highway Alignment

Highway engineering has a large amount of information, complex related structures, various types, numerous control factors along the line, and a wide range of influence. The traditional 2D design of highway survey and design has problems such as difficulty in comparing and selecting route schemes and poor design coordination, while 3D real-scene models provide more convenience for route selection.

Calculation of Earthwork Volume

Gansu is located in the Loess Plateau, mainly mountainous and hilly. In highway design, the amount of earthwork is large. In the scheme comparison and preliminary design stage, using the real-scene 3D model to calculate the earthwork volume is more intuitive and fast.

BIM Platform

- BIM Visualization Integrated Management Platform: Based on the UAV 3D oblique photography real-scene model, a comprehensive 3D dynamic BIM visualization integrated management platform is established, which can meet the characteristics of highway engineering construction projects such as "long points and lines, complex structures, and close combination with topography and geomorphology". It comprehensively interprets the work contents of design, progress, quality, and safety management from various angles, and quickly expresses the whole process of engineering construction in an intuitive way. The platform has advantages such as visualization (what you see is what you get), coordination (avoiding or reducing conflicts), accurate and controllable cost, improving work efficiency, simulation (controlling on-site conditions as early as possible), and optimization (better construction management).

- Collision Detection and Deepening Construction Design: Using the advantage of high visualization of oblique photography measurement technology, it can intuitively reflect the current landform, and can assist in some field investigation work in construction design. Rechecking the design drawings based on BIM technology can timely find problems in the design and optimize the design quality.

Project Summary

Based on the BIM 3D collaborative design of the Linkangguang Expressway, this project deeply discusses the operational advantages of the equipment equipped with Raybot DG4pro in mountainous complex terrain, and mainly draws the following conclusions:

- High-precision POS can greatly reduce the work of field image control points. Compared with traditional triangulation, it saves field operation time, reduces production costs, and improves work efficiency;

- This project has a large height difference. The use of Raybot's long-focus oblique camera can effectively improve the problems of poor accuracy of valley models and insufficient overlap of mountain top aerial photos;

- The full-frame oblique camera has a wide frame of 79525304, and the number of aerial photos with the same resolution and area is about half of that of the half-frame (60004000) camera, which saves time in interior work processing.

It can be seen that the UAV equipped with surveying camera technology not only optimizes the traditional surveying and mapping operation mode, improves production efficiency, but also can quickly provide more reliable data for highway design.