In railway engineering, survey and design represent a critical early stage that directly impacts construction quality, safety, and cost control. With the rise of 3D visualization technologies, oblique photogrammetry has emerged as a breakthrough tool, transforming traditional workflows with its ability to create highly realistic 3D models. This article, based on the engineering practices of China Railway First Survey and Design Institute Group Co., Ltd. (hereinafter referred to as “China Railway First Institute”), systematically explores the principles, accuracy control, and practical applications of oblique 3D reality modeling in railway survey and design.

1. Technical Background: Tackling the Challenge of Accuracy Control

Oblique photogrammetry uses multi-angle cameras to capture imagery, reconstructing true-to-life 3D surface models. This enables a transition from traditional “2D drawings” to “3D scenes” in railway projects. However, the lack of standardized control point deployment methods has long limited accuracy and practical adoption.

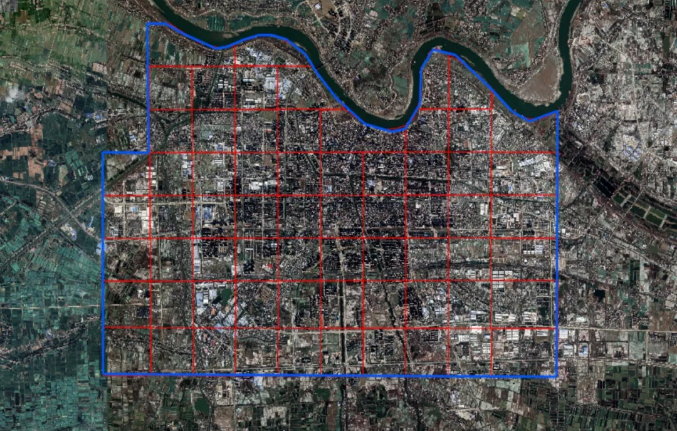

To address this, China Railway First Institute conducted a field trial in Lantian County (part of the Xi’an–Shiyan section of the Xi’an–Wuhan High-Speed Railway). The project area features flat open terrain with no tall buildings, making it suitable for precision analysis. The trial adopted the CGCS2000 national coordinate system, 1985 national elevation datum, and TM projection (central meridian 108°).

A KWTX6L electric multi-rotor UAV was equipped with a Riebo DG4 five-lens oblique camera. At 2cm ground resolution, 12 flight lines and 70 base lines were planned, with 180m flight altitude and 75%/60% forward/side overlap. A total of 110 ground control points were deployed across rooftops, road intersections, and other features for precision validation.

2. Accuracy Analysis: Optimizing Ground Control Deployment

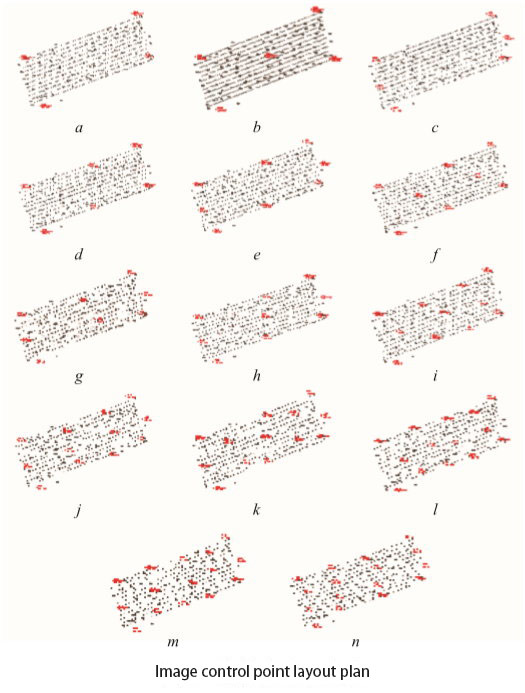

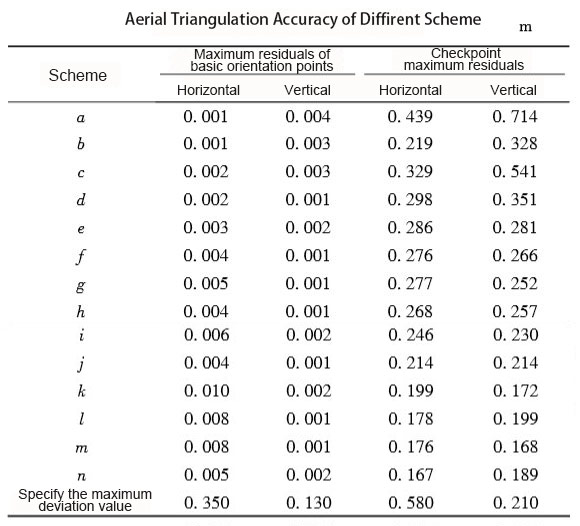

The accuracy of oblique 3D models depends heavily on control point configuration. China Railway First Institute tested 14 different schemes, evaluating both aerial triangulation and final model precision.

2.1 Aerial Triangulation Accuracy

Following Railway Photogrammetry Standards (≤0.35m horizontal and ≤0.13m vertical error for 1:500 mapping), 45 checkpoints were analyzed.

- Results showed that horizontal accuracy could be achieved with as few as 4 corner points.

- For vertical accuracy, scheme K (four corners + one central point) performed best, with maximum vertical error of 0.172m—well below the standard.

2.2 3D Model Accuracy

Using 73 checkpoints, the mean square error (MSE) was measured:

- Scheme K: 0.155m horizontal, 0.135m vertical.

- Scheme M: 0.152m horizontal, 0.102m vertical.

Both far exceeded standard requirements. Importantly, scheme K reduced the number of control points to just one-third of traditional aerial survey norms, cutting fieldwork and costs significantly.

3. Full Lifecycle Applications in Railway Engineering

With high-precision 3D models, China Railway First Institute applied the technology across railway survey, design, construction, and operation, achieving measurable improvements in both efficiency and safety.

3.1 Geological Survey: Handling Complex Terrain

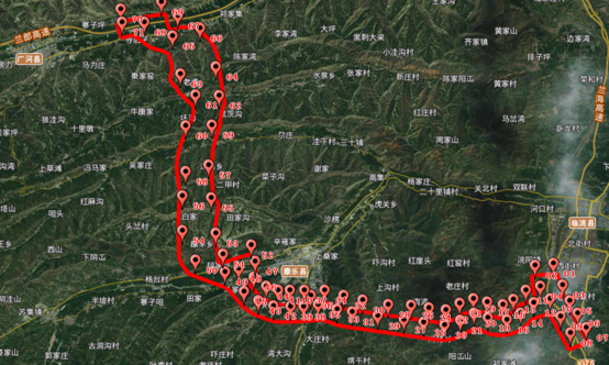

- In a Tibetan Plateau railway project, oblique models at 5cm resolution covered 680km², enabling precise identification of 19 geological hazard sites (39.13km²).

- Hazard types included faults, landslides, and unstable rock masses. Fieldwork was reduced by 40%, and efficiency doubled.

3.2 Route Selection: Enabling Visual Optimization

- On the Baoji–Chengdu Railway emergency repair section, oblique models were used to identify 21 hazardous slope segments (totaling 4.7km).

- The models also supported station planning, environmental assessment, and conflict avoidance with residential or ecological zones.

3.3 Bridge, Tunnel, and Roadbed Design: Reducing Risk

- Bridge design: By integrating BIM into 3D models, engineers detected design conflicts with pipelines and roads early. On one plateau project, this reduced bridge length by 120m, saving ~¥8M.

- Tunnel design: Oblique models supported safer tunnel portal relocation, cutting protective costs by 60%.

- Roadbed design: Dense point clouds improved earthwork volume estimation accuracy by 30% and efficiency by 50%.

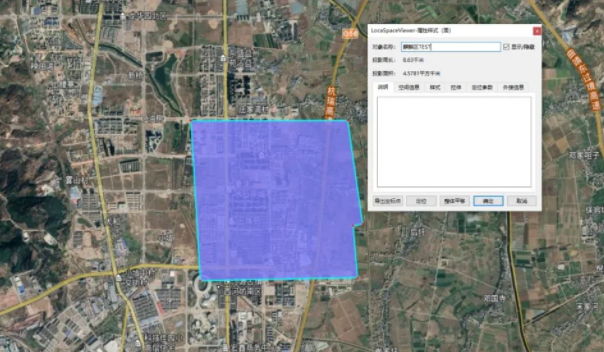

3.4 Mapping and BIM Integration: Driving Digital Transformation

- Mapping: Oblique models produced 1:500 topographic maps and cadastral updates at half the traditional cycle time.

- BIM collaboration: Serving as the GIS foundation, oblique models integrated railway BIM data across disciplines, supporting progress monitoring, quality control, and even long-term asset maintenance.

Conclusion: A Digital Future for Railway Engineering

Oblique photography 3D reality modeling is reshaping railway survey and design by solving accuracy challenges, reducing costs, and enhancing safety. From the Xi’an–Wuhan trial to applications in the Sichuan–Tibet Railway and Tibetan Plateau projects, its value has been repeatedly proven.

Looking ahead, integration with BIM, GIS, and big data will further drive railway projects toward intelligent, safe, and green construction. As a digital backbone, oblique 3D models are poised to become an indispensable tool in future railway infrastructure development.