Urban underground pipelines are often referred to as the “lifelines of a city.” Their efficient management is critical to ensuring smooth urban operations and improving living environments. In the eastern part of Jinan’s main urban area, a 3D underground pipeline visualization project based on oblique photogrammetry has provided a new solution for refined urban pipeline management, setting a benchmark for the application of reality-based 3D technology in urban governance.

Tackling the Challenges of Pipeline Management

As urbanization accelerates, the drainage network in Jinan’s main urban area has grown increasingly complex. Traditional 2D drawings and manual inspections can no longer meet modern management demands—unclear pipeline routes, vague spatial relationships, and delayed fault localization all hinder maintenance efficiency and water environment improvements.

To address these challenges, Jinan launched the “Urban Pipeline 3D Visualization Project” alongside a citywide drainage network census. By integrating oblique photogrammetry data with the city’s pipeline database, the project presents pipeline routes, layouts, attributes, and defects in an intuitive 3D spatial model, providing precise spatial information for management, fault detection, and planning decisions.

Technical Lead

The project was led by the Shandong Institute of Geological Surveying and Mapping, a multidisciplinary survey organization established in 1958 under the Shandong Provincial Bureau of Geology and Mineral Resources. With expertise spanning surveying, GIS, and big data analysis, the institute has completed thousands of projects in UAV-based oblique photogrammetry and 3D modeling. Its strong technical foundation and credibility ensured smooth project execution.

Overcoming Complex Site Challenges with Smart Flight Planning

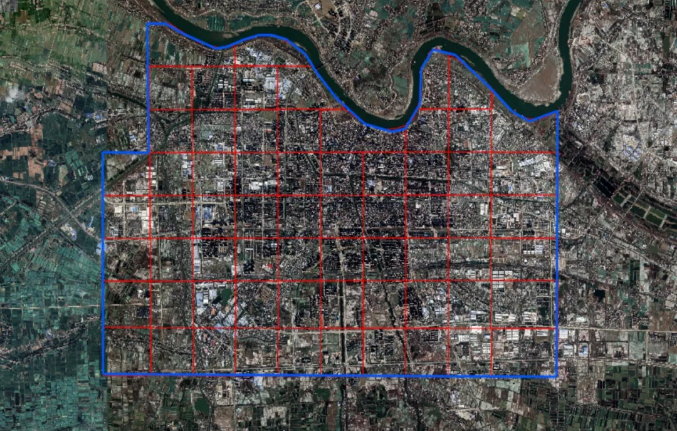

The project site, in Jinan’s eastern core, posed significant challenges: terrain sloped from south to north with a 130m elevation difference; dense, diverse buildings included both high-rises over 100m and low-rise residences, plus the 339m “Tallest Building in Jinan”; and construction sites north of the area exceeded 100m in height. These conditions demanded high-precision, safe flight planning.

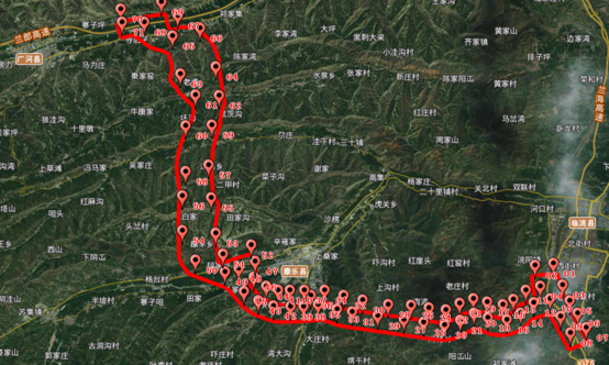

The team designed careful flight operations:

-

Conducted missions between 10 a.m. and 3 p.m. in clear, calm conditions (wind force 1–2).

-

Deployed 82 ground control points and 20 checkpoints to ensure model accuracy.

-

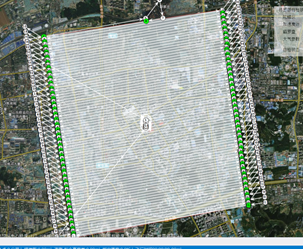

Set flight altitude at 280m, achieving 3cm GSD, covering 17.4km² of effective area (30km² total with buffer).

-

Applied 80% forward and 70% side overlap (per cadastral standards).

-

Completed 10 sorties, each lasting ~80 minutes, capturing 82,300 clear, color-balanced images.

Core Equipment & Data Collection: Precision in Practice

Given the terrain’s steep elevation differences, narrow building gaps, and wide coverage, the team used a vertical take-off and landing fixed-wing UAV equipped with the RIEBO DG4 Pros five-lens oblique camera. With a total resolution of 225MP, 56mm oblique lenses, and a 40mm nadir lens, this full-frame camera outperformed competing products. The long focal length design ensured both flight safety and detail capture in high-rise areas, guaranteeing high-precision and realistic 3D modeling.

High-Efficiency Processing & Accuracy Validation

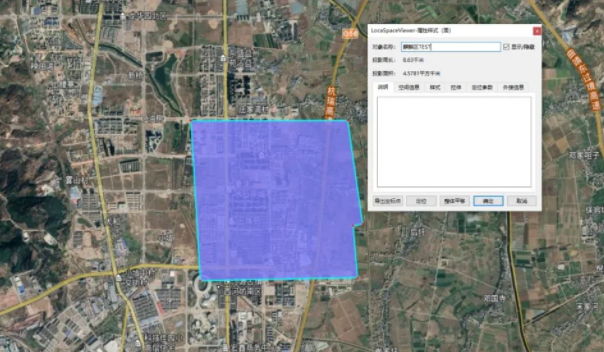

Processing such massive datasets was another challenge. Using CC software and an 80-node computing cluster (each with 64–256GB RAM, 512GB–2TB SSD storage, Nvidia GeForce 2080 GPUs, and 10GbE switching), the team processed the 82,300 images in two regions:

-

Region 1: 48,374 images, processed in 72 hours.

-

Region 2: 33,926 images, processed in 50 hours.

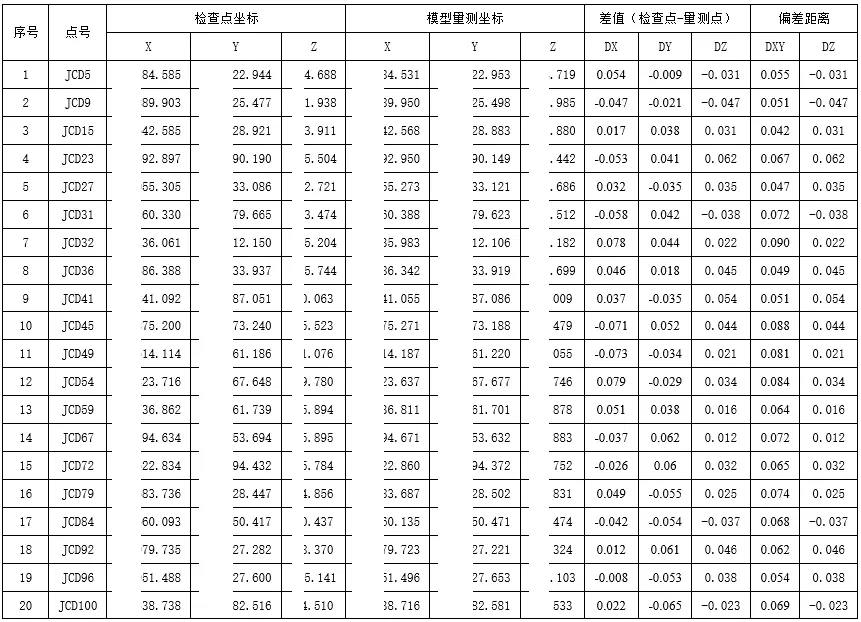

Accuracy results confirmed expectations:

-

Bundle adjustment errors were just 0.36m (X), 0.25m (Y), and 0.43m (Z).

-

3D network adjustment errors were within 0.01m.

-

Ground checkpoints further validated centimeter-level accuracy, fully meeting the needs of the drainage network 3D management platform.

From Data to Decision: Delivering Practical Value

The resulting 3D management platform delivered multiple practical functions:

-

3D Visualization: Underground pipelines are overlaid with surface models using semi-transparent views, solving the “invisible underground” challenge.

-

Precise Defect Localization: Each issue point is tied to real-world coordinates for fast troubleshooting and repair.

-

Attribute Integration: Pipeline attributes (material, diameter, depth, etc.) are linked to the 3D model for easy querying and editing.

-

Integrated Management Tools: Includes CCTV photo linking, spatial analysis, measurement, and annotation to support planning, maintenance, and emergency response.

Lessons Learned & Broader Outlook

The project proved oblique photogrammetry’s effectiveness in complex urban environments while offering key takeaways: dividing the survey area into zones, using high-performance equipment, and applying cluster-based processing balanced both efficiency and accuracy.

These experiences have strong potential for broader application:

-

Supporting “Reality-Based China” initiatives for nationwide 3D city modeling.

-

Enabling rural land-use planning and digitalized homestead management.

-

Enhancing pipeline high-consequence area monitoring and wind farm 3D design.

From underground pipelines to above-ground buildings, from urban governance to rural development, oblique photogrammetry is proving to be a powerful enabler of “Digital China.” Jinan’s practice stands as a vivid demonstration of this transformative trend.