Bridges are designed with a “design life” in mind, often 75 to 120 years, but in practice, many bridges fall short of this expectation. This gap between design life and actual service life has become one of the most pressing issues in infrastructure management.

Among different bridge types, precast hollow slab bridges are especially vulnerable. While their design makes construction faster and more economical, it also introduces structural weaknesses that lead to premature deterioration. Research shows that this problem is not random—it is caused by six major hidden defects, often cascading from hinge joint failure into system-wide damage.

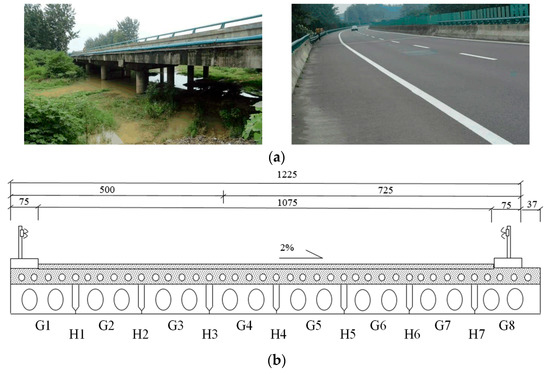

▲Hollow slab bridge in highway system: (a) an overview; (b) cross-section

To extend the service life of hollow slab bridges, engineers and managers must shift from reactive repairs to proactive, data-driven bridge inspection and maintenance. This includes better design practices, higher-quality construction, and advanced non-destructive testing (NDT) methods such as drone inspection and ground penetrating radar.

Design Life vs. Service Life: Why Hollow Slab Bridges Fail Early

Many people misunderstand what “design life” means. For example, AASHTO specifications may state a design life of 75 years, but this only guarantees structural safety under loads—it does not guarantee durability.

Service life, on the other hand, refers to how long the bridge actually remains safe and functional. It depends on material quality, construction practices, maintenance, and environmental exposure. Hollow slab bridges often fail earlier than expected because stakeholders mistake design life for a durability guarantee, overlooking the long-term risks.

Why Hollow Slab Bridges Are Vulnerable

Hollow slab bridges are widely used for short-span applications. They are built with precast hollow-core girders connected by hinge joints, reducing weight and construction costs.

But the reliance on hinge joints creates a critical weak point. If these joints are poorly built or degrade over time, the entire bridge loses load-sharing capacity. Field studies have shown that hinge joints are often the first part to fail, triggering a chain reaction of cracking, corrosion, and ultimately systemic decay.

The Six Hidden Diseases of Hollow Slab Bridges

The deterioration of hollow slab bridges follows a cascading failure model. Once one weakness appears, others follow. The six major hidden defects include:

1. Hinge Joint Failure

Hinge joints are the “key points” of hollow slab bridges. When they fail, transverse connectivity is lost, leading to uneven load distribution. This accelerates cracking and allows water and salts to seep inside, starting other deterioration processes.

2. Construction Defects (Honeycombing & Delamination)

Manufacturing flaws such as honeycombing or delamination often remain hidden until damage worsens. These defects reduce concrete strength and increase permeability, making bridges more vulnerable to corrosion once water penetrates.

3. Widespread Cracking

Transverse and longitudinal cracks not only reduce structural capacity but also serve as channels for chloride and carbon dioxide, which accelerate corrosion and carbonation. Cracks create a vicious cycle of damage that spreads quickly.

4. Chloride-Induced Reinforcement Corrosion

De-icing salts or marine environments introduce chloride ions that break down steel’s protective layer. Corroded rebar expands, causing spalling and more cracks. This is one of the most dangerous hidden diseases of concrete bridges.

5. Concrete Carbonation

Over time, atmospheric CO₂ lowers concrete alkalinity, destroying the protective film around reinforcement. Water exposure accelerates this process, making even chloride-free environments risky for long-term durability.

6. Brittle Shear and Punching Shear Failure

Unlike gradual flexural failure, shear failures are sudden and catastrophic. Because hollow slabs remove abdominal concrete, shear resistance is much lower than solid slabs. Concentrated loads, such as heavy vehicle wheels, can trigger dangerous punching shear failures.

Modern Bridge Inspection: Why Visual Checks Are Not Enough

Traditional visual bridge inspections often fail to detect hidden defects. By the time spalling or major cracks are visible, deterioration is already advanced.

Instead, advanced non-destructive testing (NDT) methods provide deeper insight:

- Ground Penetrating Radar (GPR): Detects voids, delamination, and cracks under asphalt overlays.

- Impact-Echo: Identifies delamination and hidden flaws.

- Half-Cell Potential: Locates areas of active reinforcement corrosion.

- Ultrasonic Tomography & Acoustic Methods: Reveal voids and delamination with high accuracy.

- Drone Bridge Inspection: Provides high-resolution imaging and access to hard-to-reach areas under bridges.

By combining NDT with UAV (drone) inspection, engineers can detect early-stage problems that would otherwise remain invisible until failure.

Strategies to Extend the Service Life of Hollow Slab Bridges

To address the hidden diseases of hollow slab bridges, a two-level strategy is required:

Preventative Design & Construction:

- Use high-quality, low-permeability concrete.

- Increase cover thickness over reinforcement.

- Apply corrosion-resistant reinforcement (epoxy-coated, galvanized, stainless steel).

- Enforce strict quality control during precast production and installation.

Advanced Remediation & Strengthening:

- Strengthen hinge joints with UHPC or transverse prestressing.

- Use CFRP (Carbon Fiber Reinforced Polymer) for crack repair and structural strengthening.

- Apply Fe-SMA (Shape Memory Alloy) technology for joint reinforcement.

- Replace damaged concrete to restore durability.

Conclusion

The six hidden defects of hollow slab bridges—hinge joint failure, construction defects, cracking, chloride corrosion, carbonation, and brittle shear failure—are the root causes of their premature deterioration.

By moving away from reactive repairs and adopting drone-based inspection, non-destructive testing, and data-driven Bridge Management Systems (BMS), engineers and asset managers can identify problems early and implement cost-effective maintenance.

With proactive design improvements, strict quality control, and advanced monitoring, we can extend the service life of hollow slab bridges and ensure safer, more durable infrastructure for the future.

👉 If you are looking for professional drone bridge inspection solutions to detect hidden defects and extend the service life of hollow slab bridges, contact our team today.