Beneath the calm surface of a river, powerful currents constantly interact with bridge piers. While these forces are invisible to the public, they can gradually weaken bridge foundations, leading to cracks, erosion, or even instability. For railway bridges in particular — where heavy trains pass daily — underwater inspection of bridge piers is essential to ensure long-term safety and stability.

This article explains the common underwater pier problems, why they occur, and how modern inspection technologies help engineers detect and prevent them before they become major hazards.

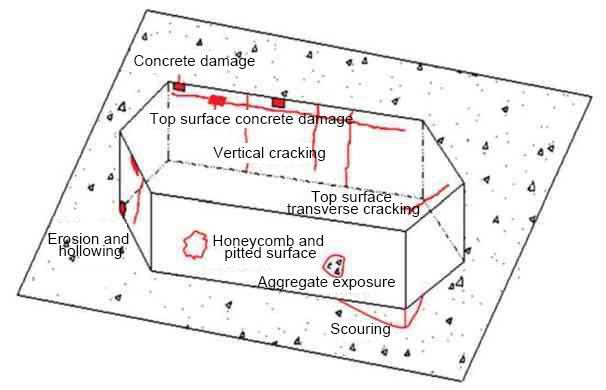

1. Common Types of Underwater Pier Damage

1.1 Scouring Around the Pier

Scouring occurs when water flow erodes and removes the soil or sediment around the pier base. This process is intensified during floods or high-flow seasons and may cause partial exposure of the foundation. If the scour depth increases continuously, it can lead to settlement or instability of the pier. Regular monitoring of scour conditions is therefore one of the most important parts of underwater bridge inspection.

1.2 Concrete Surface Damage and Cracking

Underwater concrete is often subject to erosion, abrasion, and cracking due to long-term exposure to moving water, sediment impact, and chemical corrosion. Cracks may develop on the pier surface or along construction joints, allowing water to penetrate and accelerate internal deterioration. Severe damage can cause reinforcement exposure, reducing the pier’s durability.

Engineers check for such defects through visual inspection, underwater photography, or acoustic testing, and record changes for maintenance planning.

1.3 Structural Fractures and Local Failures

In some cases, underwater bridge components such as pile caps or pier bases can develop fractures or local breakage due to high water pressure, scouring, or repeated loading. These structural defects are dangerous because they may propagate internally and affect the overall stability of the pier. Inspection focuses on identifying fracture locations, shapes, and depths to determine if reinforcement or concrete replacement is needed.

1.4 Material Degradation and Reinforcement Exposure

Long-term interaction with water, oxygen, and chemicals can cause corrosion of reinforcing steel inside the pier. Once the concrete protective layer is damaged, steel bars become exposed and start to rust, which further expands and cracks the surrounding concrete.

Such deterioration is commonly found near the scour zone, waterline, or areas with strong currents. Timely detection allows engineers to apply protective coatings, localized patching, or cathodic protection measures to slow further corrosion.

2. Underwater Inspection and Detection Methods

Underwater inspection methods vary depending on visibility, water depth, and current velocity. In modern bridge maintenance, several complementary techniques are used together to ensure accurate evaluation.

2.1 Diver Visual Inspection

This traditional but effective method relies on professional divers equipped with cameras, rulers, and underwater lighting. Divers can observe the pier’s surface directly, measure crack width and length, and assess scour or erosion depth. They also record video or photographs for later analysis.

However, this method is limited by water clarity and safety conditions, and is usually performed in stable environments.

2.2 Acoustic and Sonar Detection

When the water is too deep or turbid for divers, acoustic or sonar inspection becomes essential. Sonar devices send out sound waves that reflect off underwater structures and the riverbed. The reflected signals create an image of the pier and its surroundings, helping engineers detect scouring, cracks, or loss of material on the surface. This method is widely used because it provides accurate results even in low-visibility conditions.

2.3 Underwater Video and Photography

High-resolution underwater cameras can be operated by divers or remotely controlled vehicles. They capture clear images of cracks, exposed steel bars, and surface deterioration. The visual data is stored for comparison in future inspections, helping track the development of underwater defects over time.

2.4 Non-Destructive Testing (NDT)

NDT techniques — such as ultrasonic pulse velocity testing, impact-echo, or magnetic methods — allow inspectors to evaluate the internal condition of concrete without drilling or sampling. These tests can identify internal cracks or delamination that are invisible on the surface. They are often used together with visual inspection to provide a more complete understanding of the pier’s structural integrity.

2.5 Remote Robotic and ROV Inspection

When underwater conditions are too dangerous for divers, Remotely Operated Vehicles (ROVs) are deployed. These robots are equipped with cameras, sonar sensors, and lighting systems that can navigate around the pier and record high-quality inspection data.

Combined with AI-powered data analysis, the collected images and sonar readings can be used to automatically identify cracks, corrosion, or missing concrete. For example, Riebo’s AI Bridge Inspection Solution integrates UAV imaging above water with ROV-based underwater inspection, providing a comprehensive digital view of bridge structures from top to bottom.

3. Maintenance and Safety Measures

After inspection, engineers analyze the results to determine suitable maintenance methods, such as:

- Reinforcing scoured areas with stone protection or concrete collars.

- Applying underwater patching or grouting to repair cracks and spalled zones.

- Installing corrosion protection systems in exposed steel regions.

- Setting up long-term monitoring sensors to track scour depth and displacement.

These measures ensure that underwater piers remain stable and capable of bearing heavy railway loads for years to come.

Conclusion

Underwater pier inspection is a vital yet challenging part of bridge maintenance.

By combining traditional diving techniques with modern sonar and robotic systems, engineers can detect hidden damage that is invisible from the surface.

With the help of Riebo’s AI Bridge Inspection Solution, inspection data can now be analyzed more efficiently, providing engineers with accurate insights to plan maintenance, prevent accidents, and ensure the long-term safety of railway bridges.