As a critical part of modern transportation systems, bridge inspection plays a key role in ensuring the safe operation of bridges. Over time, due to aging, environmental exposure, and variable loads, structural damage and hidden risks become inevitable. In severe cases, such issues can lead to structural failure or even collapse, causing significant casualties and economic losses. Bridge inspection, therefore, is essential not only for maintaining traffic safety but also for extending a bridge’s service life and ensuring its structural reliability.

1. What Is Bridge Inspection?

Bridge inspection refers to the periodic and comprehensive examination of all highway bridges on public roads to ensure safe operation and prevent structural or functional failures. Its core purpose is to systematically detect defects, deterioration, and potential issues in bridge structures, thereby providing a basis for maintenance, repair, reinforcement, or replacement decisions—ultimately minimizing risks and protecting public safety.

1.1 Types of Bridge Inspection

- Routine Inspection: Typically conducted every 24 months (in the U.S.), this is the most common inspection type. It evaluates the general condition of the bridge and identifies visible defects. Inspectors often get close or physically touch the components.

- Initial Inspection: Performed after a new bridge is constructed or after major repairs to establish a baseline of its condition.

- Fracture-Critical Member Inspection: Targeted inspection of key components whose failure could lead to catastrophic collapse (e.g., tension members in truss bridges).

- Underwater Inspection: Inspects submerged components like foundations and caissons using divers and specialized underwater equipment.

- Damage Inspection: Emergency inspection conducted after natural disasters (earthquakes, floods, typhoons) or accidents (vehicle or vessel collisions).

- In-Depth Inspection: A more detailed and focused investigation prompted by findings from routine inspections. May involve NDT or load testing.

1.2 Comparison: U.S. vs. China

Type Classification:

U.S. (NBIS): Focuses on core routine inspections, with added categories like underwater and fracture-critical inspections.

China (Technical Specifications for Highway Bridge Maintenance): Offers a more detailed classification system, including initial inspection, daily patrol, frequent inspection, periodic inspection, and special inspection—emphasizing continuous, high-frequency monitoring.

Inspection Frequency:

U.S.:

- Routine: Every 24 months, extendable to 48 months based on risk assessment.

- Underwater: Up to 72 months under certain conditions.

- Fracture-critical members: Typically every 24 months.

China:

- Daily patrols: Daily or weekly.

- Frequent inspection: At least once a month.

- Periodic inspection: Every 1–3 years, depending on the bridge's condition and importance.

- Special inspection: Triggered as needed.

2. What Does Bridge Inspection Involve?

Bridge inspection covers all structural components, aiming to detect a wide range of defects and deterioration. The AASHTO Manual for Bridge Element Inspection provides detailed guidance on the process, including:

2.1 Deck System

- Wearing surface: Cracks, potholes, spalling, roughness.

- Deck structure: Cracks, spalling, rebar corrosion, water seepage.

- Expansion joints: Failures, damage, clogging, leakage.

- Sidewalks, railings, drainage: Integrity and functionality.

2.2 Superstructure

- Main girders/trusses/arches: Cracks (concrete/steel), deformation, corrosion, welding defects, loose bolts, fatigue.

- Crossbeams/secondary beams: Similar issues.

- Bearings: Aging, displacement, cracking, corrosion, deformation, malfunctions.

- Cables (cable-stayed/suspension): Corrosion, broken wires, tension loss, sheath damage.

2.3 Substructure

- Piers/abutments: Cracks, spalling, rebar corrosion, scouring, settlement, tilting, impact damage.

- Foundations: Scour exposure, pile damage, settlement (often underwater).

2.4 Ancillary & Environmental Factors

- Approaches: Settlement, cracking, drainage issues.

- Navigation clearance: Obstructions or safety hazards.

- Riverbed scour: Threats to foundation stability.

- Vegetation growth: Impact on structures.

- Vehicle impact marks.

Inspectors use methods tailored to material types (concrete, steel, wood, composites) and structure forms, including visual inspection, hammering, rebound tests, steel tape measurements, and crack width gauges, documenting the location, type, severity, and size of each defect.

3. Common Inspection Methods and Their Roles

3.1 Visual Inspection

The most basic method, relying on the human eye, often supported by tools like telescopes, crack width gauges, and cameras.

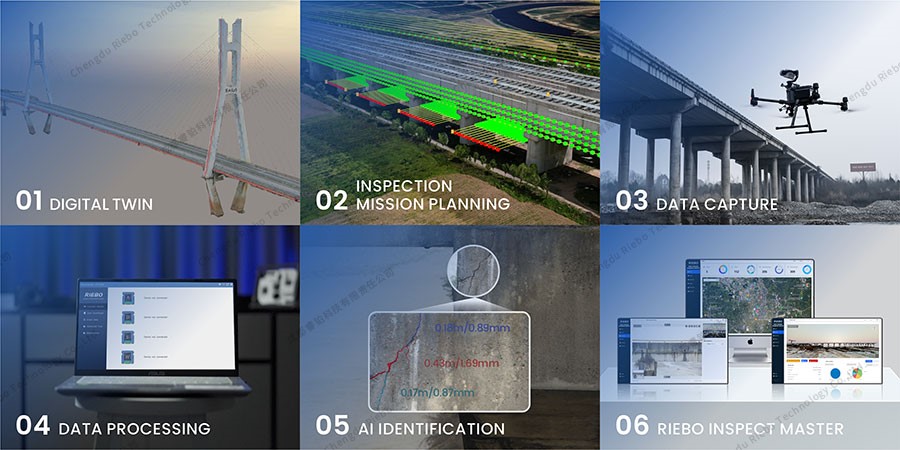

3.2 UAV Inspection with Imaging & AI

Drones equipped with high-res cameras, infrared sensors, or LiDAR can rapidly capture detailed images of bridge components—especially those at height or hard to access—greatly improving efficiency and safety. When integrated with AI, drones can automatically identify cracks, honeycombing, or surface roughness.

👉 Explore our drone bridge inspection solution

3.3 Non-Destructive Testing (NDT)

Techniques that detect internal defects and material properties without damaging the structure:

Ground Penetrating Radar (GPR): Detects subsurface layers, voids, rebar locations, and paving thickness.

Ultrasonic Testing (UT): Identifies internal cracks and voids in concrete/steel.

Infrared Thermography (IRT): Detects voids, delaminations, or moisture using surface temperature differences.

Acoustic Emission (AE): Monitors micro-cracks or fiber breaks inside materials.

Electrochemical Methods: Evaluate rebar corrosion activity and predict future deterioration.

Magnetic Particle / Liquid Penetrant Testing (MPT/LPT): Detect surface or near-surface cracks in steel.

3.4 Static & Dynamic Load Testing

Applies loads to evaluate real-world stress response, vibration behavior, and load-carrying capacity.

3.5 Structural Health Monitoring (SHM)

Uses IoT and sensor networks (strain, displacement, acceleration, temperature) installed on key parts of a bridge for continuous real-time monitoring. Data is transmitted wirelessly for centralized analysis.

4. Integration and Challenges of Traditional & Drone Inspection Technologies

Modern bridge inspection is evolving toward a hybrid model that combines manual expertise with intelligent technologies. While traditional methods remain crucial, drone-based solutions are rapidly emerging as essential supplements.

4.1 Challenges of Traditional Methods

Low efficiency, high cost: Deploying inspection vehicles, setting up scaffolding, and closing lanes is time-consuming and expensive.

High safety risks: Workers operate at heights or in complex structural zones.

Blind spots: Some areas are inaccessible, like underneath beams or deep valleys.

Low digitalization: Manual recording and image capture make it difficult to build complete digital archives.

4.2 Rise and Challenges of Drone-Based Inspection

Advantages:

- Rapid panoramic and detailed image acquisition.

- Supports various sensors (HD cameras, LiDAR, thermal imaging).

- Integrates with AI and digital twin systems for automated analysis and archiving.

Challenges:

- Complex flight environments: Narrow spaces, dense structures, variable wind, weak GPS signals.

- High data volume: Large image sets and 3D models require powerful processing tools.

- Lack of standardized procedures: Operational and evaluation methods still evolving.

4.3 Collaborative Integration Is the Future

The trend is toward combining traditional and UAV-based methods:

- Use drones and AI for fast data capture and preliminary screening.

- Follow up with manual checks or NDT for suspicious areas.

- Integrate multi-source data into unified platforms for lifecycle digital bridge health management.

For instance, RIEBO’s drone bridge inspection solution integrates ultra-high-resolution imaging, 3D modeling, and intelligent recognition—greatly improving inspection efficiency and data reliability, setting a new standard for modern bridge assessment.