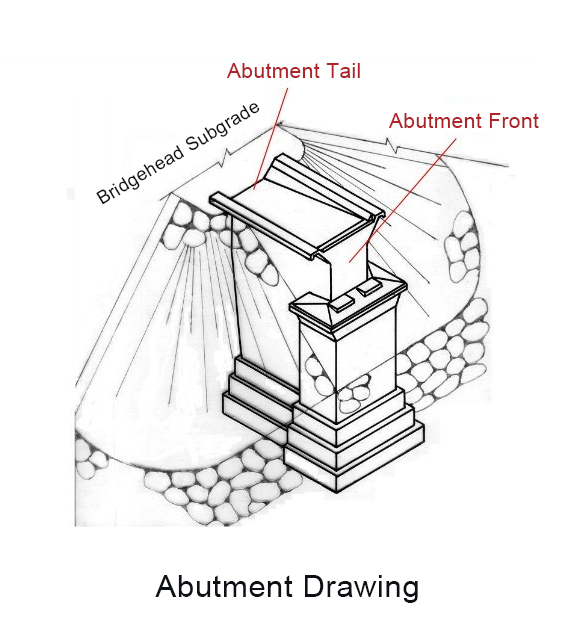

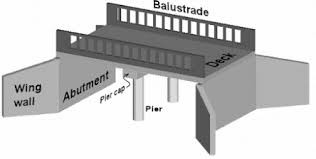

In every bridge, the abutment plays a critical role as the connection between the superstructure and the ground. It supports the bridge span, retains the earth behind it, and ensures a smooth transition between the bridge deck and the approach embankment.

Understanding how bridge abutments are designed, structured, and built helps engineers and inspectors ensure both safety and durability of bridge systems.

1. What Is a Bridge Abutment?

A bridge abutment is a part of the bridge’s substructure that supports the end of the bridge span and connects it to the approach road or embankment. It performs three main functions:

- Supports vertical loads from the bridge deck through the bearings

- Resists lateral earth pressure from the backfill behind the abutment

- Provides structural stability and alignment for the bridge and roadway

In short, the abutment is the foundation element that anchors the bridge in place, both structurally and geotechnically.

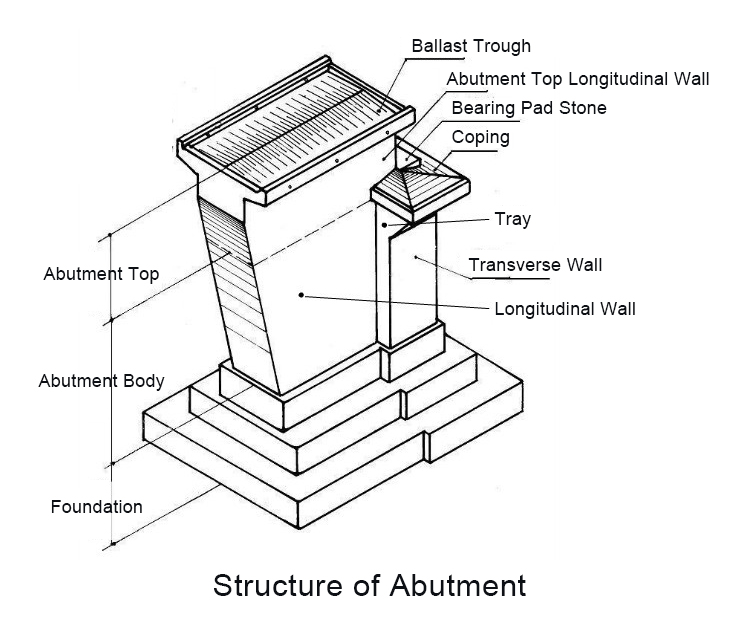

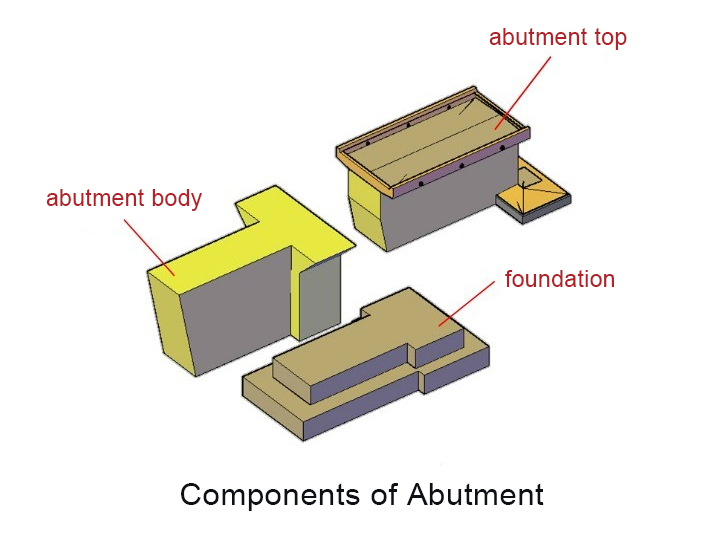

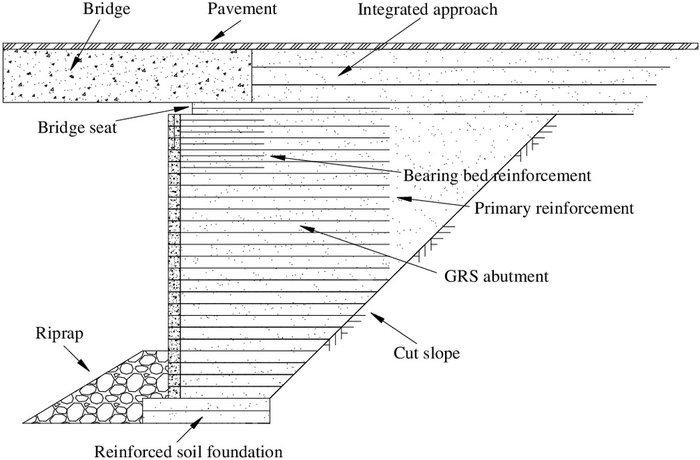

2. Main Components of a Bridge Abutment

A typical bridge abutment consists of several interconnected parts, each with a specific role in load transfer and stability.

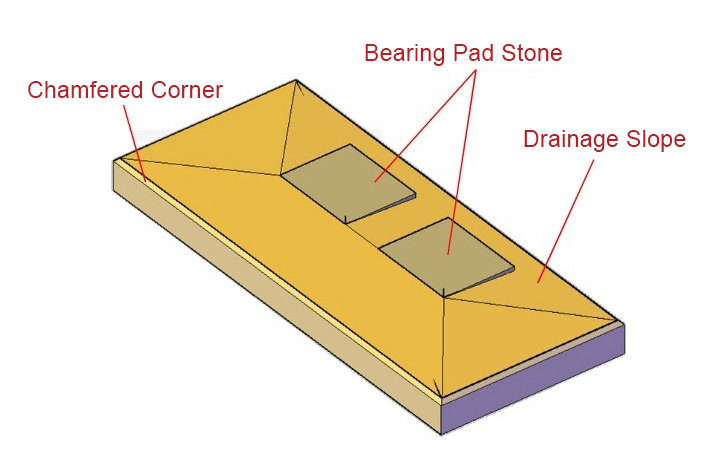

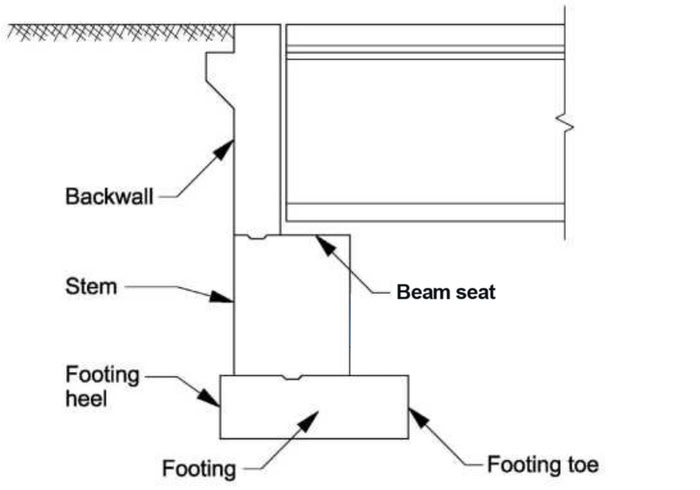

(1) Bridge Seat / Bearing Area

The bridge seat is the flat surface at the top of the abutment where bearings are installed. It transfers loads from the superstructure (girders or deck) to the abutment below.

(2) Backwall (Stem Wall)

The backwall retains the soil behind the bridge and prevents the approach embankment from sliding. It also forms the vertical surface where the expansion joint is usually located.

(3) Wing Walls

Wing walls extend from both sides of the abutment to hold the fill material and guide water drainage. They stabilize the soil near the abutment and prevent erosion.

(4) Footing or Foundation

The footing distributes all vertical and horizontal loads to the ground. It can be a spread footing, pile foundation, or combined footing, depending on soil conditions.

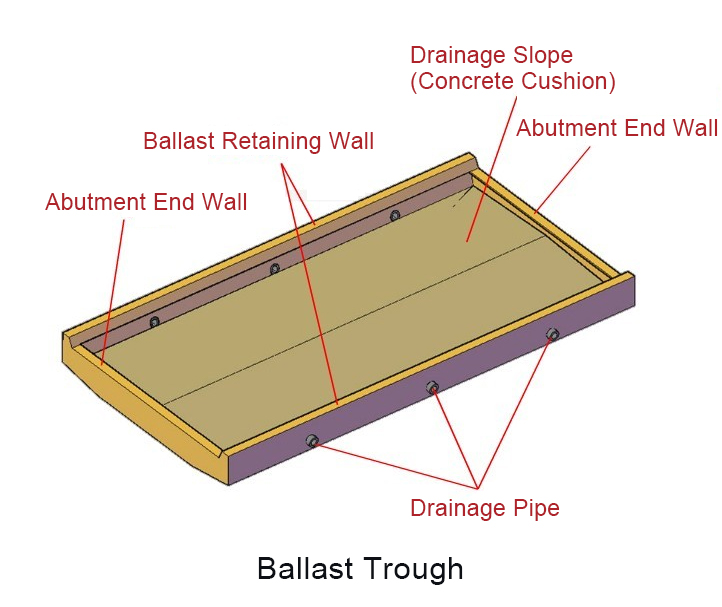

(5) Drainage System

Proper drainage behind the abutment reduces hydrostatic pressure. Weep holes, filter layers, and perforated pipes are often used to discharge water safely.

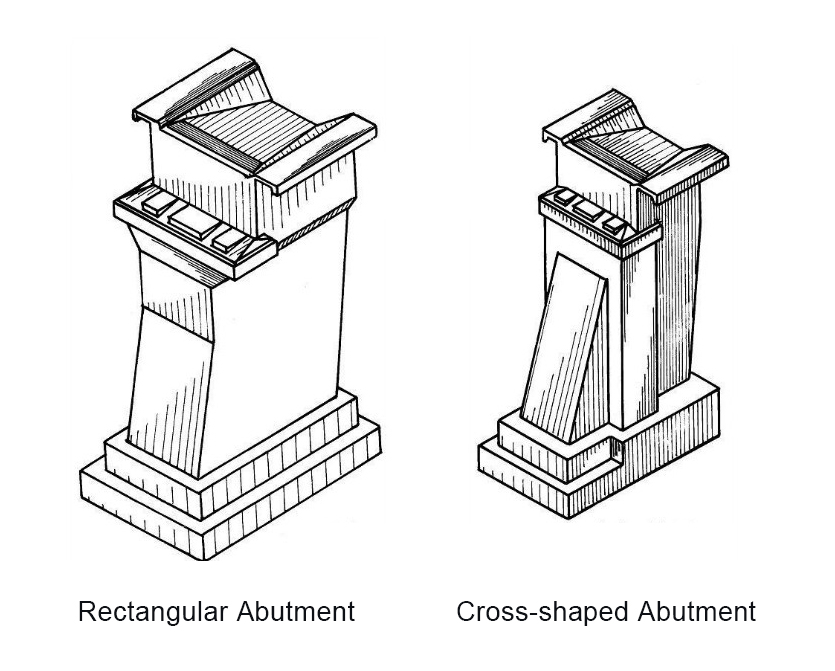

3. Common Types of Bridge Abutments

Bridge abutments are classified by their structural form and how they resist loads.

Here are the most widely used types in modern bridge construction:

(1) Gravity Abutment

A gravity abutment relies on its own weight to resist earth pressure and loads.

It is typically made of mass concrete and used for small to medium-span bridges with firm foundations.

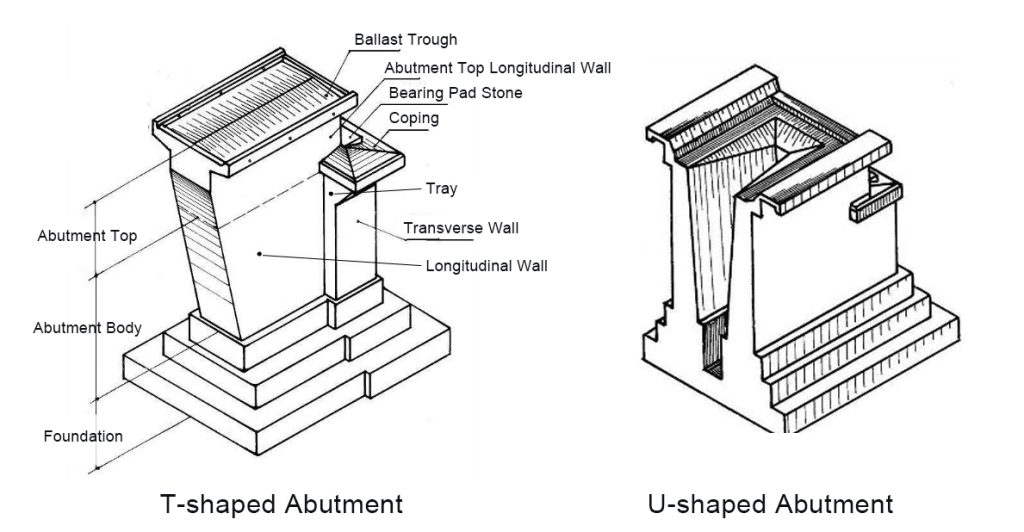

(2) Cantilever Abutment

This type uses a reinforced concrete stem wall that acts as a vertical cantilever.

It efficiently resists earth pressure through bending action and requires less material than gravity abutments.

(3) U-Shaped Abutment

A U-shaped abutment features extended wing walls forming a U configuration.

It provides excellent soil retention and is often used in high embankments or urban overpasses.

(4) Pile-Supported Abutment

Used in weak soil conditions, pile-supported abutments transfer loads to deeper, stronger strata through piles.

This design minimizes settlement and improves stability in soft ground.

4. Structural Details and Reinforcement Design

Proper detailing ensures that the abutment remains safe and serviceable under all load combinations.

- Footing Reinforcement: Bottom reinforcement bars resist bending caused by soil and vertical loads.

- Stem Wall Reinforcement: Vertical and horizontal bars handle bending moments from earth pressure.

- Backwall and Wing Wall Bars: Control cracking and maintain stability.

- Bearing Seat Reinforcement: Designed to resist concentrated loads from bridge bearings.

Additionally, drainage and expansion joints must be integrated into the design to prevent water damage and accommodate temperature movements.

5. Construction and Maintenance Considerations

- Backfill and Compaction: Proper compaction reduces lateral pressure and prevents settlement.

- Waterproofing and Drainage: Ensure drainage behind the wall to prevent hydrostatic buildup.

- Transition Slab: A reinforced concrete slab connects the bridge deck and roadway, reducing differential settlement.

- Erosion Control: Wing wall extensions and surface protection prevent scour around the footing.

6. Conclusion

Bridge abutments may look simple from the outside, but they are highly engineered systems that balance load-bearing, earth-retaining, and durability requirements.

A well-designed abutment not only supports the bridge but also ensures a smooth and safe approach for vehicles for decades.

In bridge engineering, the abutment is more than a foundation — it’s the structural handshake between the bridge and the earth.