As vital hubs of urban transportation, bridges not only support heavy traffic flow but also represent the engineering and economic development of a city. With rapid urbanization, increased vehicle loads, and the growing prevalence of heavy trucks, modern bridges are required to sustain heavier and more frequent loads.

However, corrosion and fatigue in steel structures have become major causes of bridge deterioration and safety incidents. Therefore, timely detection, maintenance, and reinforcement of steel structure bridges are crucial to ensure safety, extend service life, and reduce maintenance costs.

1. Current Situation of Steel Structure Bridges

In earlier decades, bridges were primarily constructed with reinforced concrete. With the advancement of steel materials and fabrication technology, steel structure bridges have become increasingly popular in pedestrian bridges, highway bridges, and railway bridges.

Steel bridges offer significant advantages:

- High strength-to-weight ratio,

- Easy installation and assembly,

- Fast construction speed.

However, during welding, assembly, and long-term operation, steel structures inevitably develop defects. These small imperfections can evolve into cracks, corrosion, and fatigue fractures due to cyclic loading, environmental exposure, and temperature variation.

When such deterioration progresses, structural deformation and instability can occur, reducing load-bearing capacity and, in severe cases, leading to bridge collapse. Common causes include:

- Prolonged overloading,

- Environmental corrosion,

- Natural disasters such as floods or typhoons.

While corrosion is unavoidable, protective coatings, anti-corrosion materials, and timely inspection can significantly slow down deterioration and extend service life.

2. Inspection of Steel Structure Bridges

The inspection of steel structure bridges focuses on:

- The condition of surface coatings and paint layers,

- Detection of rust, cracks, deformations, or holes,

- Examination of bolts, rivets, and welds for corrosion, fatigue, or damage,

- Inspection of drainage areas and moisture-prone zones, which often exhibit accelerated rusting.

3. Testing Technologies for Steel Structure Bridges

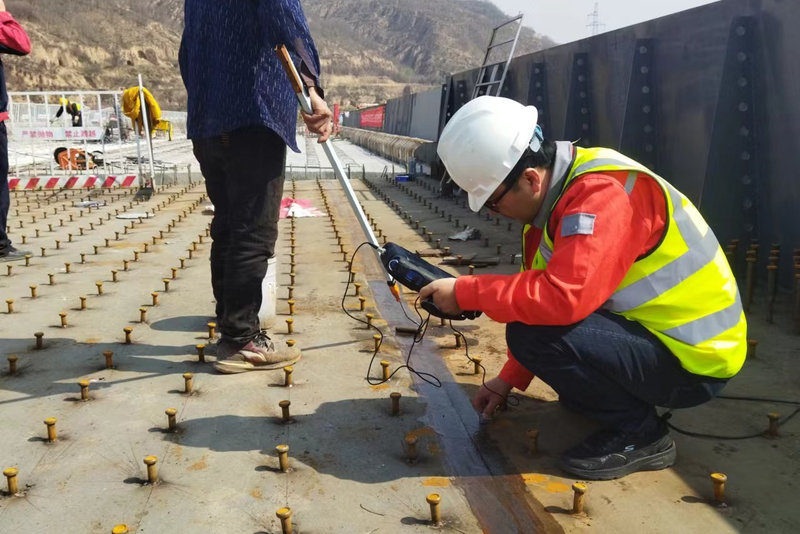

3.1 Non-Destructive Testing (NDT) Methods

Non-destructive testing allows the detection of internal and surface defects without damaging the bridge components, using physical phenomena such as sound, light, magnetism, and radiation.

Key NDT technologies include:

- Magnetic Particle Testing (MT):

Magnetic powder is applied to a magnetized steel surface; cracks or holes distort magnetic field lines, revealing surface defects under proper lighting. - Ultrasonic Testing (UT):

Ultrasonic waves are transmitted through steel. Reflected signals from defects are displayed on an oscilloscope, helping identify defect location and size.

Variants include conventional ultrasonic testing and Time-of-Flight Diffraction (TOFD), which improves accuracy. - Eddy Current Testing (ECT):

By analyzing changes in induced eddy currents, this method detects defects in plates and tubular structures. - Liquid Penetrant Testing (PT):

A fluorescent dye penetrates surface cracks via capillary action. After wiping and applying a developer, defects become visible under ultraviolet light. - X-Ray and Gamma Ray Testing (RT):

Radiation penetrates materials and forms an image on film, allowing quantitative analysis of internal voids, cracks, or inclusions. - Acoustic Emission Testing (AE):

Stress waves emitted from active defects are recorded to identify crack propagation and fatigue behavior. Though still developing, this method is valuable for real-time structural monitoring.

3.2 Corrosion Detection Techniques

Corrosion inspection focuses on evaluating thickness loss, corrosion rate, and structural degradation:

- Ultrasonic Guided Wave Testing:

Measures the thickness of steel plates and pipes to identify thinning due to corrosion. Provides rapid, direct visualization of defect locations. - Eddy Current Corrosion Testing:

Detects wall thinning and material degradation through electromagnetic response analysis. - Visual and Microscopic Inspection:

Simple but effective — visual checks or magnified observation of corrosion surfaces after rust removal help assess severity. - Linear Polarization Resistance (LPR) Method:

Measures the relationship between polarization potential and current to estimate real-time corrosion rate, suitable for continuous monitoring. - Electrical Resistance Probe Technique:

Uses a thin metal probe inserted into the structure; as corrosion reduces cross-sectional area, resistance increases, allowing quantitative corrosion depth measurement.

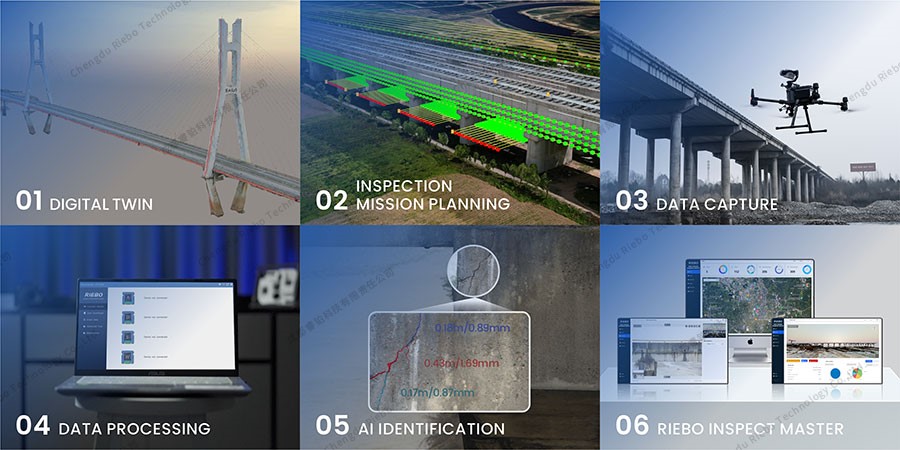

Riebo’s Drone Bridge Inspection Solution in Steel Structure Assessment

In addition to traditional NDT and corrosion detection, Riebo’s Drone Bridge Inspection Solution provides a modern, efficient supplement for steel bridge monitoring.

Equipped with high-resolution cameras and AI-assisted defect recognition, Riebo’s drones can:

- Inspect hard-to-reach steel members, towers, and under-deck areas,

- Identify rust, coating damage, or deformation from multiple angles,

- Capture 3D models and image datasets for quantitative corrosion analysis.

This aerial perspective reduces inspection time, minimizes safety risks, and ensures comprehensive coverage of steel bridge components—especially for large spans and complex geometries.

4. Maintenance and Reinforcement Techniques for Steel Bridges

After inspection and evaluation, if a steel bridge no longer meets load-bearing requirements, strengthening or reconstruction is necessary. The main goals of reinforcement are to improve structural safety, minimize downtime, and preserve the original aesthetics.

Common strengthening methods include:

- Prestressing Method:

Adds prestressed tendons to tensile zones, increasing load capacity and reducing cracks. - Adding Longitudinal or Transverse Girders:

Reduces stress on existing beams and enhances overall stability. - Steel Plate Bonding:

Bonds steel plates to structural members to share loads and increase cross-sectional strength; this method is simple and efficient. - Structural System Modification:

Alters load paths or adds supports to redistribute stresses, though this approach is complex and costly. - Transverse Connection Enhancement:

Improves load distribution uniformity and boosts global bridge capacity.

Regular and effective reinforcement not only extends the bridge’s service life but also supports the safe and sustainable development of transportation infrastructure.

Conclusion

Steel structure bridges, though strong and versatile, are susceptible to corrosion, fatigue, and environmental damage. By integrating advanced non-destructive testing technologies, corrosion monitoring, and aerial inspection tools like Riebo’s Drone Bridge Inspection Solution, engineers can achieve faster, safer, and more comprehensive assessments—ensuring bridges remain reliable landmarks of modern cities.