Spray-applied rapid-setting rubber asphalt waterproof coating is widely recognized as a reliable and efficient material for protecting bridge decks, tunnels, and other concrete structures. This type of coating combines the advantages of polymer-modified asphalt and spray technology to create a seamless, durable, and highly elastic waterproof membrane. It has become a preferred choice in large-scale civil engineering projects such as highways, subways, water treatment facilities, and municipal bridges due to its strong adhesion and long-lasting waterproof performance.

How the Spray-Applied Coating Works

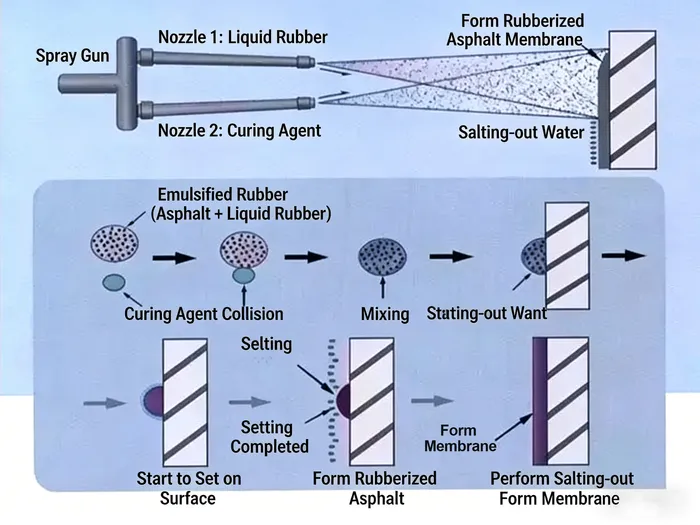

This waterproof coating is formed by spraying two liquid components—typically a polymer-modified asphalt emulsion (component A) and a curing agent (component B)—through a specialized dual-spray nozzle. Once the two components mix in the air, a rapid chemical reaction occurs, resulting in instant gelation and membrane formation within seconds.

The coating forms a dense, continuous, and joint-free film that effectively isolates water and moisture from the structure surface. Its seamless nature helps eliminate the weak points found in traditional roll-type membranes, ensuring consistent and reliable waterproof protection.

Key Features and Advantages

1. Rapid Curing

The coating cures within 3–5 seconds after application, significantly improving construction efficiency. It allows for continuous spraying over large areas and minimizes downtime between coating and subsequent construction work.

2. Seamless Waterproof Layer

Because the membrane is spray-applied, it creates a fully integrated, joint-free waterproof barrier. This ensures complete surface coverage and reduces the risk of leakage or water penetration at joints and overlaps.

3. Excellent Elasticity and Crack Resistance

The cured rubber asphalt membrane has high elongation and flexibility, allowing it to accommodate substrate deformation, structural vibration, and thermal expansion without cracking or delamination.

4. Strong Adhesion and Durability

The material bonds tightly to concrete, metal, and asphalt surfaces. Its high-density polymer network provides excellent resistance to wear, puncture, and aging, making it suitable for long-term exposure to harsh environmental conditions.

5. Chemical and Weather Resistance

The coating offers outstanding resistance to acids, alkalis, salts, and various industrial chemicals. It also performs well under UV exposure and fluctuating temperatures, ensuring stable waterproof performance over time.

6. Applicability on Damp Surfaces

Unlike many traditional waterproof coatings, spray-applied rubber asphalt can be applied directly on damp concrete. This feature greatly enhances construction flexibility and helps maintain project schedules even in humid or rainy conditions.

Applications in Infrastructure Waterproofing

Spray-applied rapid-setting rubber asphalt waterproof coating has been widely used in multiple infrastructure fields, including:

- Bridge decks and expansion joints – to prevent seepage and extend the service life of bridge structures.

- Subways and tunnels – for sealing against groundwater infiltration.

- Underground parking garages and basements – to protect concrete surfaces from moisture damage.

- Municipal and hydraulic projects – such as reservoirs, culverts, and sewage treatment facilities.

Its combination of rapid curing, seamless application, and long-term durability makes it especially effective for bridge deck waterproofing, where reliability and efficiency are crucial.

Conclusion

As a proven and high-performance waterproofing solution, spray-applied rapid-setting rubber asphalt coating has demonstrated its value across a wide range of engineering applications. Its seamless structure, strong elasticity, and superior adhesion ensure that bridge decks and concrete infrastructures remain well-protected from water damage and corrosion.

By integrating material science with modern construction methods, this technology continues to provide dependable, efficient, and cost-effective waterproofing protection for today’s demanding infrastructure projects.