Bridges are the “backbones” of transportation networks — their health directly determines road connectivity and public safety.

Traditional manual inspection relies heavily on visual judgment and experience, making it inefficient, error-prone, and unsuitable for challenging environments such as bridge undersides or high-altitude wind zones.

The Riebo AI Bridge Inspection System was designed to overcome these limitations. By integrating AI algorithms, professional-grade imaging sensors, and an intelligent management platform, Riebo builds a complete “data acquisition–processing–analysis–decision” loop, becoming a true intelligent guardian for bridge safety.

Core Architecture: The “Perception–Brain–Command Center” of Riebo

The Riebo system is built on three key pillars — accurate data acquisition, intelligent analysis, and efficient management.

Through deep integration of its data acquisition system, AI analysis engine, and Tongtu intelligent management platform, Riebo addresses the fundamental weaknesses of traditional inspection.

From stable UAV operations in complex environments to millimeter-level defect detection and full digitalized workflow management, every step reflects Riebo’s commitment to intelligent precision.

Data Acquisition System: “Eyes” That See Clearly in Complex Environments

Riebo’s UAV bridge inspection platform is powered by the DJI M350 RTK (including some other commercial UAVs), a high-performance drone built for demanding industrial use.

It maintains stable flight even under bridge structures, in strong winds, or confined spaces — ensuring uninterrupted data collection.

To solve the GNSS signal weakness often encountered beneath bridges, the system integrates an Inertial Navigation System (INS) and multi-source fusion positioning, guaranteeing precise trajectory control and accurate positioning.

This innovation eliminates the long-standing challenges of “inaccurate flight and incomplete coverage,” providing reliable operational stability for complex bridge environments.

Professional Payloads and Smart Planning: The Formula for Millimeter-Level Precision

The accuracy of inspection data depends on two critical factors — professional-grade sensors and intelligent flight planning.

Riebo’s UAV system carries two primary sensors:

- The R10Pros photogrammetry camera enables centimeter-level 3D modeling, generating accurate digital twins of bridge structures.

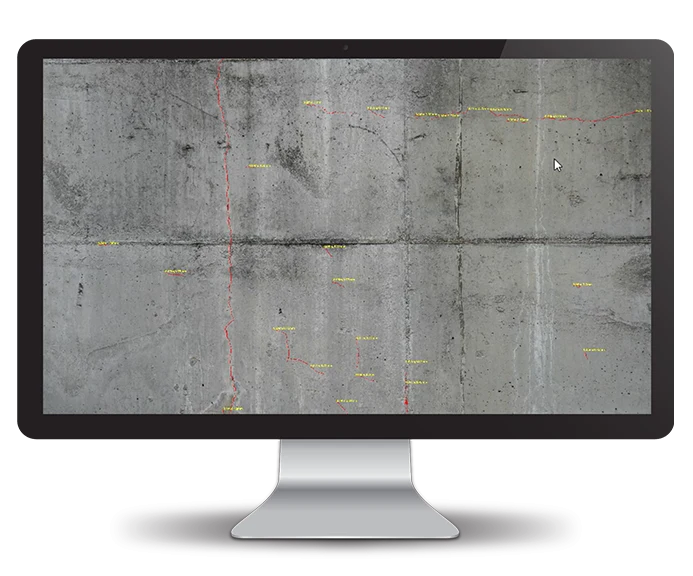

- The SF10 LiDAR detection camera captures 0.1 mm-level microcracks, spalling, and rebar corrosion with exceptional clarity — far beyond human visual capability.

To guarantee full data coverage, Riebo’s AeroMapPro flight planning software automatically generates optimal flight paths based on centimeter-level 3D bridge models. It ensures high image overlap and eliminates blind spots from the start. Operators can dynamically adjust flight altitude and angles in real time, improving flexibility.

After data capture, the SkyScanner preprocessing tool manages massive image datasets, supporting batch export, geographic embedding, and field-of-view calculations — providing standardized data for defect localization and subsequent analysis.

AI + Intelligent Management: The “Brain and Nerve Center” of the System

If the UAV and sensors serve as the “eyes,” then Riebo’s AI analysis engine and Tongtu intelligent management system act as the “brain” and “central nervous system.”

Trained on a vast database of bridge defect imagery, Riebo’s AI engine automatically identifies cracks, spalling, and corrosion, and accurately quantifies key metrics such as length and width.

This eliminates subjective bias and fatigue-related errors in manual analysis.

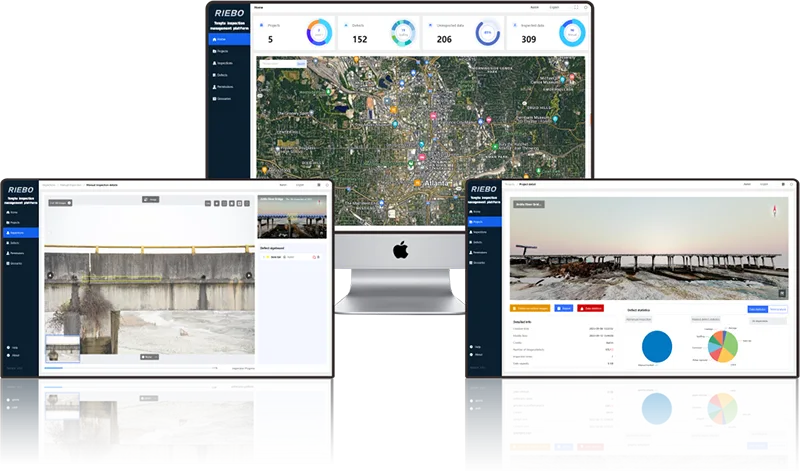

The Tongtu platform seamlessly connects all inspection stages — from task scheduling and data uploading to defect analysis and report generation — realizing true end-to-end management across the entire inspection workflow.

Core Value: See Clearly, Analyze Accurately, Manage Efficiently

Riebo’s true value lies not only in its precision but also in how it redefines bridge management. Through 3D visualization in the Tongtu platform, AI-detected defects are automatically mapped onto the corresponding positions of the bridge’s digital twin model — making each issue visibly traceable. Decision-makers can literally “see” every potential risk.

With data traceability and trend prediction, the system tracks defect evolution over time and forecasts deterioration rates, offering scientific guidance for predictive maintenance. Meanwhile, automated report generation produces standardized documentation instantly, streamlining workflows and improving efficiency.

Real-World Advantages and Applications

In practice, the Riebo AI Bridge Inspection System delivers measurable benefits:

- Large-span bridges: UAVs combined with LiDAR achieve full coverage up to 5× faster than manual inspection.

- Aging bridges: High-resolution 3D models reveal degradation patterns, supporting accurate repair decisions and preventing resource waste.

- Complex environments: Strong adaptability removes the need for risky high-altitude operations, ensuring personnel safety.

Compared with traditional inspection, Riebo enables three key transformations: from reactive maintenance to predictive warning, from experience-based assessment to data-driven decision-making, and from fragmented management to closed-loop control.

This aligns perfectly with the industry vision of using technology to extend bridge service life, making Riebo a cornerstone of bridge lifecycle management.

Intelligent Technology Safeguarding the Lifeline of Transportation

As cities expand and bridge maintenance demands intensify, the Riebo AI Bridge Inspection System brings innovation that overcomes traditional limitations. With its professional-grade hardware, powerful AI algorithms, and efficient management platform, Riebo acts as a digital health guardian for every bridge — from coastal megastructures to urban viaducts.

By integrating AI, imaging, and smart analytics, Riebo offers precise, safe, and efficient solutions that empower modern infrastructure safety.

Looking ahead, Riebo will continue deepening the fusion of AI and imaging technologies, lowering deployment costs, and expanding compatibility across various bridge types — truly realizing the goal of “every bridge under intelligent protection.”