As critical nodes in railway transportation networks, railway bridges bear long-term and repeated dynamic train loads while being exposed to complex and ever-changing natural environments. Their structural health is directly linked to the safety and efficiency of railway operations. With increasing service years, bridge structures inevitably develop various defects, and without timely treatment, these can lead to deterioration of structural performance, reduced load-bearing capacity, or even severe safety incidents.

This paper systematically reviews common types of railway bridge defects based on their structural characteristics and operating environments, analyzes their causes, and proposes targeted treatment strategies.

Common Defects of Railway Bridges and Cause Analysis

Railway bridges are structurally complex, and defects differ significantly depending on the component. Broadly, they can be divided into superstructure defects, substructure defects, and ancillary facility defects.

(1) Superstructure Defects

As the core component directly bearing train loads, the superstructure frequently develops defects in the girders, deck system, and bearings.

Girder Defects

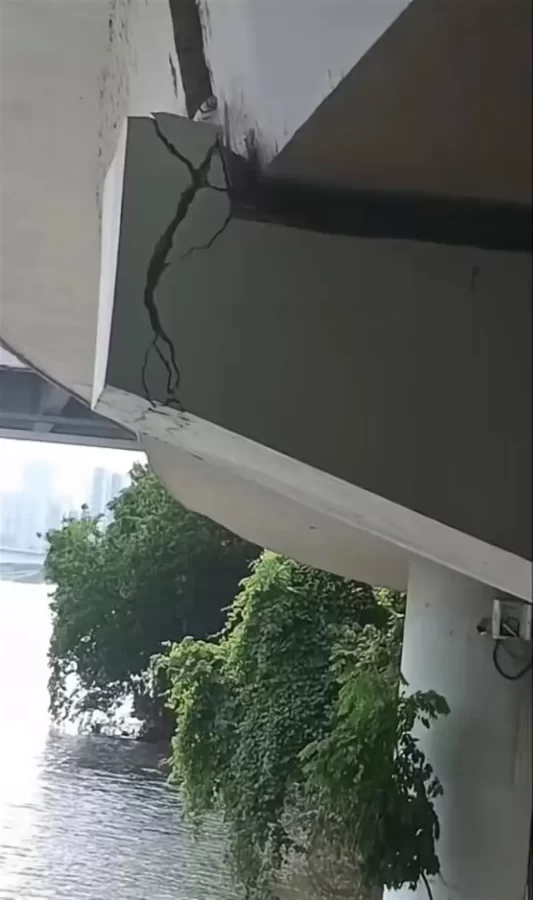

- Cracks: The most common girder defect, classified by cause into load-induced cracks, temperature cracks, and shrinkage cracks. Load cracks typically occur near mid-spans and supports due to overstress from repeated dynamic loading or overloading. Temperature cracks, usually irregular or longitudinal, result from constrained thermal expansion/contraction under diurnal and seasonal variations. Shrinkage cracks, fine surface networks, arise during concrete curing when volume changes are not properly controlled.

- Carbonation and Spalling: Carbonation occurs when CO₂ penetrates concrete and reacts with hydration products, lowering alkalinity and breaking down the passive film on reinforcing steel, which then corrodes. Expansion from corrosion induces tensile stresses in surrounding concrete, causing spalling and exposure of reinforcement, thereby reducing load capacity.

- Steel Girder Corrosion and Fatigue Damage: Steel trusses and plate girders are prone to corrosion, especially in humid or industrial environments containing chlorides or sulfur dioxide. Repeated train loading induces fatigue cracks at stress concentrations (welds, bolted joints), which may propagate and cause sudden failure.

Deck System Defects

- Pavement Damage: Manifested as cracking, raveling, potholes, or spalling. Causes include incompatibility of pavement and girder deformation, loss of waterproofing leading to water ingress and freeze-thaw cycles, or material degradation such as asphalt aging.

- Expansion Joint Damage: Common issues include aging or rupturing rubber seals, corroded/deformed steel sections, and clogged gaps. These impair sealing, waterproofing, and expansion functions, generating additional stresses.

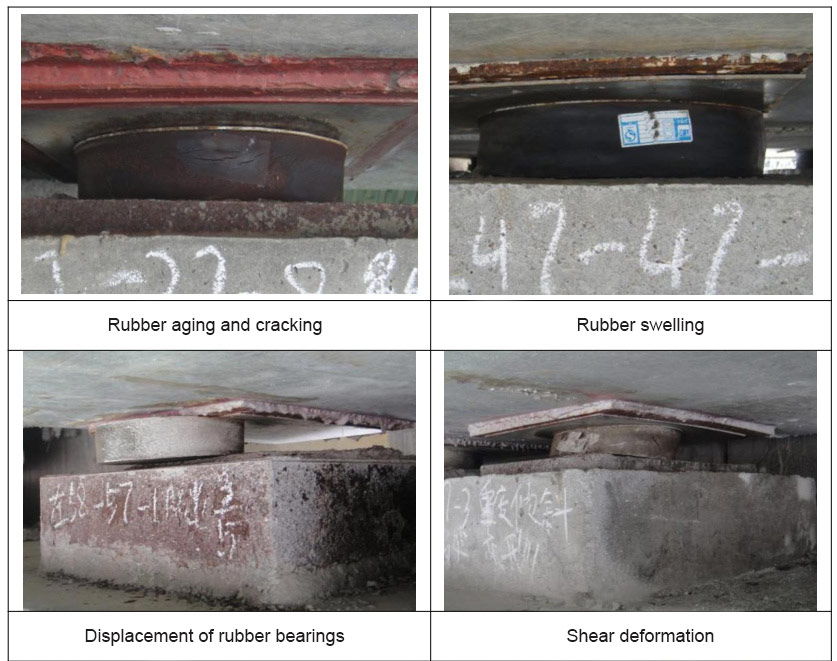

Bearing Defects

- Aging and Deformation: Rubber bearings may develop aging, cracking, bulging, or excessive shear deformation. Pot bearings may suffer steel corrosion, seal aging and leakage, or PTFE plate wear, impairing rotation and sliding.

- Void Formation and Eccentric Loading: Gaps may form between bearings and girders/bedstones due to creep, misalignment, or uneven seats. Eccentric loading causes uneven stress distribution, accelerating bearing failure and inducing girder damage.

(2) Substructure Defects

The substructure—piers, abutments, and foundations—primarily suffers from settlement, environmental erosion, and load effects.

Pier Defects

- Cracks and Carbonation: Causes mirror those of girders, including load, temperature, and shrinkage cracks. Being partially below ground or in fluctuating water levels, piers face more severe carbonation and corrosion, leading to section loss and reduced capacity.

- Tilt and Settlement: Caused by uneven foundation settlement, excavation disturbance, or scour. Tilting alters girder stress distribution, while excessive settlement may cause misalignment, affecting train smoothness.

- Cracks and Damage: Resulting from vertical loads from girders and lateral earth pressure from backfill, commonly occurring at connections and mid-sections. Inadequate compaction behind abutments accelerates stress-related cracking.

- Backfill Settlement and Bumping: Poor-quality fill, groundwater fluctuations, or compaction issues cause settlement, leading to a height difference at track transitions. This produces “bumps” when trains pass, reducing ride comfort and inducing impact loads.

Foundation Defects

- Settlement: Caused by inadequate bearing capacity, weak soil layers, karst cavities, or insufficient ground treatment. Uniform settlement may be tolerable, but differential settlement leads to tilting and cascading superstructure defects.

- Scour and Erosion: For river crossings, floodwaters scouring around foundations reduce embedment depth or even expose foundations, threatening stability.

- Corrosion: Aggressive groundwater containing chlorides or sulfates can degrade concrete and corrode reinforcement or steel, reducing foundation strength.

(3) Ancillary Facility Defects

Though not directly load-bearing, ancillary systems are critical for safety and protection. Common defects include:

- Waterproofing Failure: Manifested as blistering, cracking, or peeling, allowing water ingress and accelerating corrosion.

- Damage to Railings and Barriers: Corrosion, deformation, or loosening of railings and breakage of fences compromise safety and aesthetics.

- Drainage Blockage: Clogged deck drains or pier scuppers cause water accumulation, which worsens pavement and girder deterioration.

Key Technologies for Railway Bridge Defect Treatment

Railway bridge maintenance should follow the principle of “prevention first, combining prevention and treatment, adapting to local conditions, and ensuring economy and rationality.” Treatment must be tailored to defect type, severity, and structural features.

(1) Inspection and Assessment

Accurate inspection forms the basis for sound treatment decisions. Methods include:

- Visual Inspection: Manual patrols and UAV imagery to document visible cracks, spalling, or corrosion.

- Nondestructive Testing (NDT): Ultrasonic, rebound, or radar techniques to assess strength, internal voids, crack depth, or corrosion without damaging the structure.

- Load Testing: Static or dynamic load tests to evaluate structural response and load-bearing capacity.

- Long-Term Monitoring: Installing sensors on critical bridges to track deformation, settlement, bearing loads, and environmental parameters in real time.

(2) Superstructure Treatment

- Girder Crack Repair:

- <0.15 mm: surface sealing with epoxy.

- 0.15–0.5 mm: pressure grouting with epoxy or cementitious material.

- 0.5 mm: structural strengthening (steel plate or CFRP bonding) before grouting.

- Carbonation/Spalling Repair: Remove deteriorated concrete, clean and coat reinforcement, restore section with repair mortar or shotcrete, and apply protective coatings.

- Steel Girder Repair: Remove rust, repaint, weld cracks, or strengthen with CFRP or stiffeners. Severely reduced sections require plate splicing.

- Deck Pavement Renewal: Remove damaged layers, repair waterproofing, and repave with high-performance asphalt or fiber-reinforced concrete.

- Expansion Joint Maintenance: Replace aged rubber, corroded steel, or entire devices as needed, ensuring sealing and periodic cleaning.

- Bearing Replacement and Adjustment: Jack girders, remove old bearings, and install new ones on leveled seats. Correct eccentric loading by adjusting bearing height or girder geometry.

(3) Substructure Treatment

- Pier Repair: Similar crack and carbonation treatment as girders; strengthen with steel plates or CFRP.

- Tilt/Settlement Correction: Grouting to strengthen foundations; in severe cases, use underpinning, pressure piles, or corrective weighting.

- Abutment Repair: Grouting cracks; reinforce backfill with compaction or retaining structures. Settlement can be mitigated with improved fill or transition slabs.

- Foundation Treatment: Ground improvement via jet grouting, stone columns, or mixing piles; underpinning with micro-piles for uneven settlement.

- Scour Protection: Install riprap, masonry aprons, or concrete mats. Fill exposed zones with stone, sandbags, or underwater concrete.

- Corrosion Protection: Apply protective coatings or jackets; cathodic protection for steel; ground treatment to neutralize aggressive environments.

(4) Ancillary Facility Treatment

- Waterproofing Repair: Replace with high-performance coatings, ensuring continuity and protective overlays.

- Barrier Repair: De-rust, repaint, replace damaged parts, and restore fencing.

- Drainage Cleaning: Routine debris removal, high-pressure flushing, or system upgrades to enhance drainage.

Preventive Measures for Railway Bridge Defects

Effective prevention significantly reduces defect occurrence through optimized design, strict construction control, and refined maintenance.

- Design Stage: Choose durable materials, properly arrange joints and bearings, and ensure adequate drainage. In corrosive environments, use weathering steel or corrosion-resistant concrete.

- Construction Stage: Control material quality and workmanship; ensure proper concrete placement, vibration, and curing; follow standards for bearing installation and waterproofing.

- Operation and Maintenance Stage: Establish comprehensive inspection systems, regularly clean decks and drains, strengthen inspections after extreme weather, and employ long-term monitoring on critical bridges.

Conclusion

Railway bridge defects result from combined effects of loads, environmental erosion, and material degradation, making their treatment complex and systematic. With the expansion of railway networks and increasing service ages, defect prevention and maintenance are becoming more challenging.

Future development should focus on innovative inspection technologies (AI-based detection, UAV autonomous inspection), new material applications (ultra-high-performance concrete, advanced anti-corrosion materials), and intelligent maintenance systems, transitioning from reactive repair to proactive prevention.

This will comprehensively enhance the safety and durability of railway bridges, providing a solid guarantee for safe and efficient railway operations.