Bridge pile foundations are known as the “underground lifeline” of bridges — they bear the full load of the structure and directly determine the bridge’s safety and service life. However, since pile foundations are buried deep underground, traditional testing methods are often costly, time-consuming, and can even cause secondary damage.

This is where non-destructive testing (NDT) technologies come in — the invisible guardians that ensure pile quality without harming the structure.

Why Non-Destructive Testing Is Essential for Bridge Pile Foundations

Most bridges in China and worldwide rely on pile foundations. Complex geological conditions, construction deviations, and material inconsistencies can easily lead to hidden defects such as diameter reduction, concrete segregation, or reinforcement corrosion. If left undetected, these defects may evolve into cracks, fractures, or even structural collapse over time.

The biggest advantage of NDT lies in its ability to inspect pile quality without damaging the structure. It accurately detects internal defects such as cavities and cracks, verifies construction quality, and offers a balance of low cost and high efficiency, making it a key tool in modern bridge quality management.

Common Non-Destructive Testing Methods for Bridge Pile Foundations

Different NDT methods focus on different aspects of pile quality. Choosing the right method depends on the pile’s material, environment, and design.

1. Ultrasonic Testing – “Seeing Through” the Pile Interior

By installing sonic tubes inside the pile, ultrasonic waves are transmitted and received. When internal defects (like cracks or voids) exist, the wave velocity and amplitude change noticeably.

Ultrasonic inspection system detecting internal defects in a bridge pile foundation

This technique provides a visualized inspection of internal conditions and is highly effective in detecting concrete segregation or inclusions, offering wide coverage and precise results.

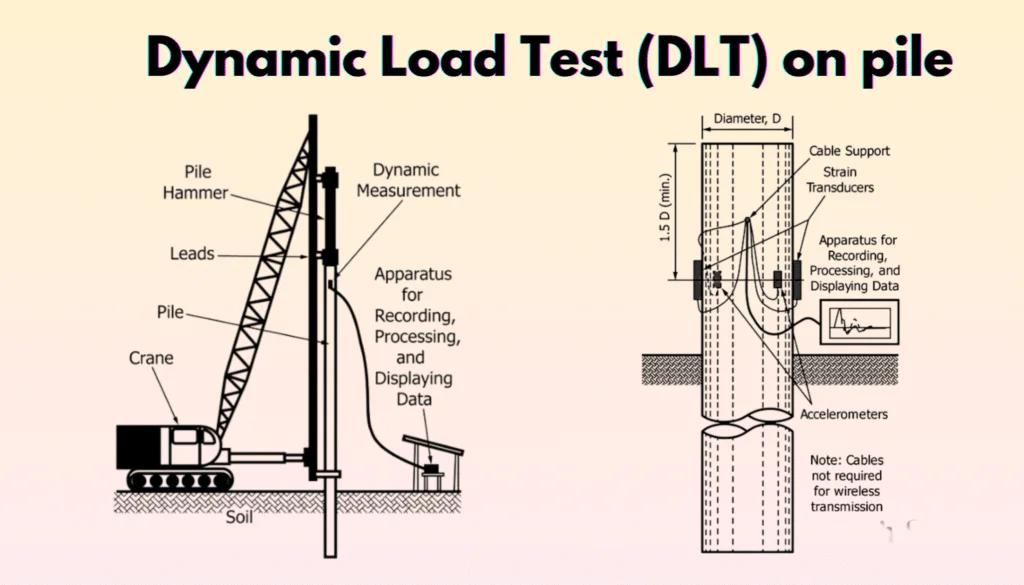

2. High-Strain Dynamic Testing – Evaluating Load Capacity

A heavy hammer is used to strike the pile top, simulating an extreme load condition. By analyzing stress wave propagation, engineers can evaluate bearing capacity and integrity. It is ideal for large bridge projects, as it directly verifies if the pile meets design load requirements — though it causes slight plastic deformation during testing.

3. Low-Strain Testing – Fast Integrity Screening

Using a lightweight hammer to tap the pile head, this method treats the pile as an elastic rod and interprets reflected stress waves to identify anomalies. It’s simple, fast, and cost-effective, suitable for preliminary screening of shallow cracks or necking, though the results rely more on the tester’s experience.

4. Core Drilling – Precision Sampling Verification

A diamond drill extracts a concrete core sample from the pile for visual and mechanical analysis. This allows for direct assessment of concrete strength, segregation, or sediment thickness. Although accurate, it’s slower and more invasive — typically used as a validation method to verify results from other NDT techniques.

Challenges and Optimization of NDT in Pile Foundation Testing

Despite its maturity, NDT still faces several challenges:

- Limited detection depth for certain surface defects

- Lack of standardized procedures across different methods

- Need for improved multi-technology coordination

To overcome these, the industry is focusing on three key directions:

- Technology Adaptation – Match NDT methods to the pile’s geological and material conditions.

- Precision Operation – Standardize sensor installation and data recording to minimize human error.

- Digital Empowerment – Integrate AI and big data to enhance signal interpretation and ensure more reliable results.

The Future: Intelligent and Integrated Non-Destructive Testing

As bridge construction moves toward longer spans and heavier loads, the need for more advanced inspection grows. Future NDT systems will evolve toward multi-technology integration and AI-powered analysis — combining ultrasonic and core sampling for both full coverage and pinpoint accuracy.

In this transformation, Riebo’s Drone Bridge Inspection Solution is playing a pivotal role. By integrating high-resolution imaging, AI defect recognition, and digital data analysis, Riebo’s drones can complement NDT work — especially for difficult-to-access bridge areas such as piers, decks, and substructures.

This synergy enables faster, safer, and smarter bridge health assessments, safeguarding the true “lifeline” of infrastructure.

Conclusion

Non-destructive testing stands as the core defense for bridge safety, protecting the invisible foundation beneath our infrastructure. As intelligent technologies and drone-based inspection solutions continue to advance, the “invisible guardian” of bridge pile foundations will become even more powerful — ensuring structural integrity and extending the life of vital transportation networks.