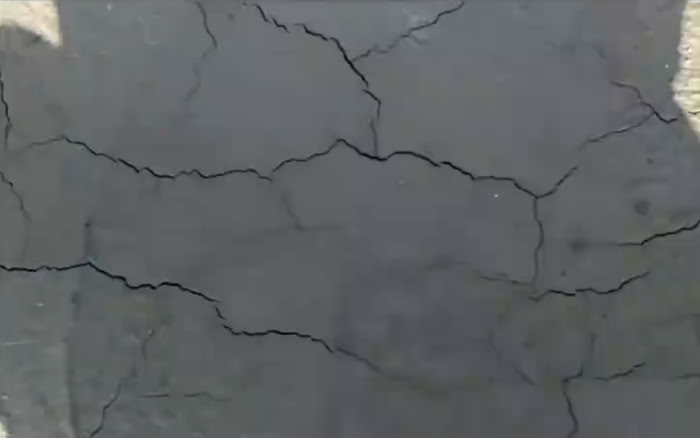

Bridge cracks are among the most common issues affecting the durability and safety of concrete structures. If not detected and repaired promptly, cracks can expand under environmental and load stresses, leading to corrosion, concrete spalling, and even structural failure.

Understanding how these cracks form — and how to effectively repair them — is essential for ensuring the long-term health of bridges.

1. Causes of Concrete Cracks in Bridges

(1) Shrinkage Cracks

Shrinkage cracks occur as concrete hardens and loses moisture. When cement hydrates, the total volume of the reaction products is less than the original materials, causing chemical shrinkage. Meanwhile, as water evaporates from the surface, drying shrinkage occurs.

Because drying starts from the surface, there is a moisture gradient between the outer and inner layers — the surface contracts more than the interior. This uneven shrinkage generates tensile stress on the surface and compressive stress inside.

When surface tension exceeds the tensile strength of concrete, shrinkage cracks form.

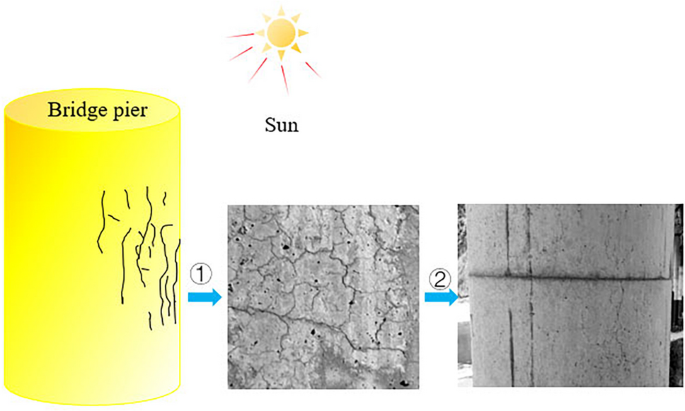

(2) Temperature Cracks

Temperature cracks result from thermal expansion and contraction caused by heat from cement hydration, sunlight, ambient temperature, or welding. Concrete has poor thermal conductivity — in large concrete masses, the inner temperature remains high while the surface cools faster.

This difference leads to internal expansion and external contraction, producing temperature stress. When these stresses exceed the material’s strength, cracks appear. Improper temperature control during curing or rapid temperature change during winter construction can also cause cracking.

Additionally, differential movement between old and new concrete sections often generates temperature-related cracks along the interface.

(3) Load-Induced Cracks

(a) Flexural Cracks:

When a bending moment acts on a beam, tension develops at the bottom. Cracks form where bending stress is greatest — typically mid-span for positive moments and near supports for negative moments. As loads increase, cracks lengthen, widen, and multiply, gradually spreading across the tension zone.

(b) Shear Cracks:

Also known as diagonal cracks, they occur near supports where shear stress is highest. These cracks typically initiate at the bottom and extend upward at an angle of 25°–50°. If cracks expand toward the compression zone, immediate reinforcement is required.

(c) Tensile (Through) Cracks:

In tension members, cracks form across the full section when concrete’s tensile strength is exceeded. Initially, cracks are narrow and acceptable within design limits, but once rebar yields and deformation increases, the structure approaches failure.

(4) Corrosion-Induced Cracks

When reinforcement steel corrodes, the rust expands up to 2–4 times its original volume, exerting pressure on the surrounding concrete. This leads to longitudinal cracking, delamination, and rust stains on the surface.

Common causes include:

- Poor concrete quality or inadequate cover thickness,

- Carbonation reducing alkalinity,

- Chloride intrusion from salt or marine environments.

Corrosion reduces the steel’s cross-section, weakens bond strength, and accelerates further cracking — forming a vicious cycle that can eventually cause structural failure.

Preventive measures include ensuring proper cover thickness, high concrete density, and careful control of chloride content in admixtures, especially in coastal regions.

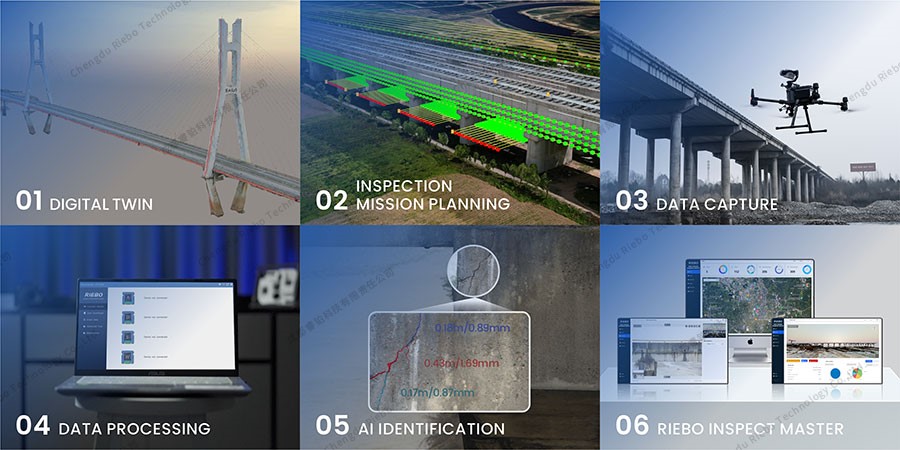

2. Riebo’s Drone Bridge Inspection Solution: Advancing Crack Detection and Maintenance

Timely identification of cracks is critical, but manual inspection — especially on large or high bridges — is labor-intensive and potentially dangerous. Riebo’s Drone Bridge Inspection Solution provides a safer, smarter alternative for modern bridge monitoring.

Equipped with high-resolution cameras and AI-driven analysis, Riebo’s drones can:

- Capture close-up imagery of bridge surfaces, beams, and decks to identify crack width, length, and pattern;

- Access hard-to-reach or elevated areas without scaffolding or traffic disruption;

- Monitor crack development over time through repeatable flight paths and automated comparison;

- Support engineers with 3D mapping and defect documentation for precise maintenance planning.

By integrating drone inspections into the maintenance process, bridge authorities can detect early-stage deterioration, reduce inspection time, and enhance safety — ensuring structural reliability and longer service life.

3. Crack Repair Methods

(1) Surface Sealing Method

A protective resin coating is applied along fine surface cracks to prevent moisture or chemicals from entering. For moving cracks, flexible epoxy or tar-epoxy materials are used. In areas with dense or widespread cracking, large-area coatings may be applied.

(2) Deep-Groove Filling Method

Cracks are first grooved along their path and then filled with bonding materials such as epoxy mortar, asphalt, or synthetic resin to restore integrity.

(3) Shotcrete Overlay

After roughening the cracked surface, a dense layer of cement mortar or concrete is sprayed to seal cracks and strengthen the member. Depending on structural needs, reinforcing mesh or additional bonding agents may be added.

(4) Steel Band Reinforcement

When major stress cracks occur, steel hoops or bands are installed perpendicular to the crack direction. These can be made from flat or round steel bars and are calculated based on the structural stress requirements.

(5) Steel Plate Bonding

Steel plates (typically 4.5–6 mm thick) are bonded over cracked areas using epoxy adhesives, forming a composite section that improves load-carrying capacity.

(6) Epoxy Injection Beneath Steel Plates

Spacers create a gap between the steel plate and concrete surface. Epoxy resin is then injected under pressure, ensuring complete filling and bonding. This method is particularly effective for irregular or uneven surfaces, though more time-consuming.

3. Conclusion

Bridge cracks may arise from shrinkage, temperature variation, mechanical loading, or reinforcement corrosion — but each can be mitigated through proper inspection and repair. With the integration of advanced drone technology like Riebo’s Drone Bridge Inspection Solution, engineers now have a more efficient and safer way to detect, analyze, and repair cracks, ensuring bridges remain safe, durable, and serviceable for decades.