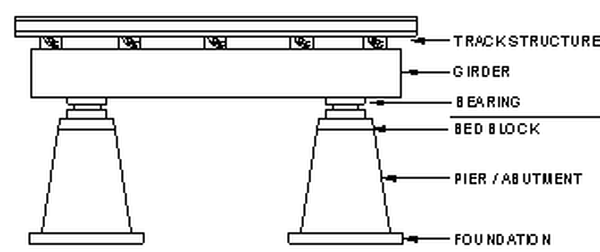

Railway bridge bearings are essential structural components that connect the superstructure (bridge deck) with the substructure (piers and abutments). They transfer loads and accommodate movements caused by traffic and environmental conditions. However, during service, bearings often develop a variety of defects that can reduce load-bearing capacity, accelerate structural damage, and pose serious safety risks. Therefore, a comprehensive understanding of the causes of bearing defects and effective prevention strategies is critical for ensuring railway bridge safety and longevity.

1. Importance of Railway Bridge Bearings

1.1 Core Load Transmission

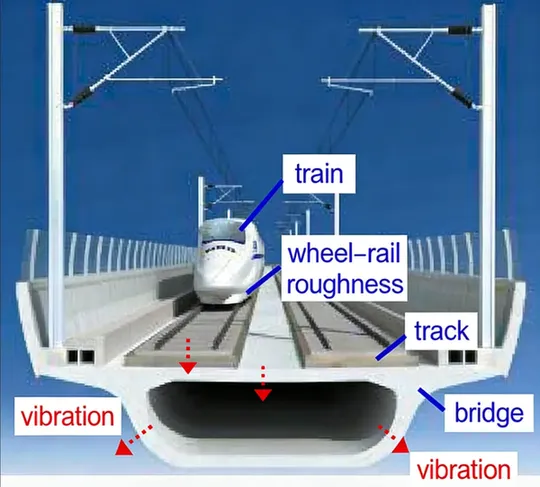

Bearings distribute static loads (such as deadweight) and dynamic loads (from high-speed trains) from the deck to the supporting piers and ultimately the foundation. Because railway trains operate at high speeds and with frequent cycles, the precision of load transfer is paramount. Uneven force transfer can lead to uneven stresses, local cracking, and structural imbalance.

1.2 Structural Protection and Vibration Damping

Railway bearings not only transfer loads but also absorb high-frequency vibration and provide protective damping to minimize fatigue damage. Specialized bearings (e.g., with lead cores) can even help dissipate seismic energy and maintain structural stability under extreme conditions.

2. Root Causes of Bearing Defects

2.1 Material-Related Defects

Material quality directly affects bearing performance and lifespan:

- Rubber Bearings: Poor anti-aging additives, low elasticity, or weak bonding between rubber and steel plates can accelerate cracking and elasticity loss.

- Metal Components: Steel with insufficient yield strength or poor corrosion resistance may deform under load or corrode in harsh environments.

- Composite Components: Weak bonding between PTFE (polytetrafluoroethylene) sliding plates and steel can lead to wear and reduced movement adaptability.

2.2 Construction and Installation Deficiencies

Faulty installation and quality control are primary contributors to bearing defects:

- Poor Leveling and Alignment: Inaccurate leveling or misaligned centerlines can cause abnormal stresses under load.

- Incomplete Grouting: Improper or insufficient grout leads to voids that decrease load-bearing efficiency.

- Improper Bolt Installation: Loose or incorrectly torqued anchor bolts compromise stability.

- Sealing Errors: Faulty sealing lets in water, debris, and contaminants that accelerate internal corrosion and damage.

- Inspection Gaps: Inadequate post-installation performance checks allow defective bearings to enter service unnoticed.

2.3 Operational and Environmental Factors

Long-term use under dynamic loads and environmental stresses also contributes to bearing deterioration:

- Fatigue from Train Loads: Repeated train cycles cause stress accumulation and cracking.

- Temperature Cycling: Thermal expansion and contraction accelerate material aging and cracking.

- Corrosive Environments: Industrial acid rain or coastal salt fog increases corrosion risk.

- Maintenance Neglect: Failure to regularly clean, lubricate, and inspect allows small defects to become major problems.

3. Prevention and Maintenance Strategies

3.1 Material Control and Quality Assurance

- Ensure all materials meet railway standards.

- Test rubber components for elasticity and aging resistance.

- Use corrosion-resistant metal treatments (hot-dip galvanizing, fluorocarbon coatings).

- Store materials properly in dry, ventilated conditions.

3.2 Construction Quality Management

- Use precision instruments (total stations, levels) to ensure accurate installation.

- Apply correct grouting processes with vibration and curing controls.

- Torque anchor bolts strictly to design specifications.

- Seal bearings effectively to prevent moisture and dust intrusion.

- Perform multi-stage acceptance inspections including load and displacement tests.

3.3 Daily Maintenance & Monitoring

Build a “daily monitoring – periodic inspection – defect repair” closed-loop system:

- Daily Monitoring: Use sensors to track displacement, stress, and environmental conditions.

- Quarterly & Annual Inspections: Visual checks, ultrasonic tests, and infrared scans to detect hidden defects.

- Early Defect Treatment: Address minor issues (e.g., small cracks, bolt loosening) promptly before they escalate.

3.4 Design Optimization

- Carefully calculate load and movement requirements.

- Select bearing types appropriate to bridge span, traffic type, and environmental conditions.

- Consider extreme events (earthquakes, floods, typhoons) in the design phase.

- Reserve maintenance access and sensor interfaces for efficient long-term inspection.

4. Conclusion

Railway bridge bearing defects arise from complex, interconnected causes, including material quality, construction practices, and operational stresses. A systematic approach—starting from material selection through design, installation, and routine maintenance—can significantly reduce the frequency and severity of bearing issues. Continuous improvement in technology and inspection protocols will further enhance the safety and service life of railway bridges.