As bridge maintenance demands become increasingly refined and intelligent, the industry is seeking technological solutions to standardize inspection workflows, maximize efficiency, and ensure precision in results. Leveraging its expertise in drones, visible-light photogrammetry, LiDAR, and digital twin technologies, RIEBO has developed a closed-loop drone bridge inspection solution. Covering preparation, execution, and management, this standardized system not only addresses the limitations of traditional inspections—such as difficulties in covering complex structures and insufficient data accuracy—but also redefines the entire inspection process through digitalization. This article outlines the specific execution steps of RIEBO’s drone bridge inspection, providing a practical roadmap for the industry to adopt intelligent inspection practices.

1. Preparation: Building the Digital Twin and Planning Accurate Flight Routes

(1) Centimeter-Level Digital Twin Modeling

During the initial inspection, RIEBO employs its M-Series professional photogrammetry cameras mounted on the DJI M300 RTK drone platform to capture high-precision 3D data of bridges. Equipped with patented MLE lenses and MLS shutters, the cameras ensure distortion control within 0.3‰, improve tie-point matching by 10–20%, and eliminate rolling shutter artifacts and low-temperature issues, guaranteeing data accuracy.

With the proprietary Riebo Route Assistant (RRA) software, flight routes and image acquisition are optimized for maximum modeling efficiency. Field tests show that a 500-meter bridge can be surveyed in just 17 minutes, producing a centimeter-level 3D reality model in 94 minutes. This model faithfully reproduces the bridge’s structure and details, serving as both the digital foundation for defect visualization and the key reference for autonomous flight route planning.

(2) Intelligent Route Planning for Full Coverage

Based on the generated digital twin, RRA automatically creates simulated inspection routes. Unlike conventional aerial surveys, bridge inspections require detection of cracks as small as 0.1 mm, demanding close-range yet safe flight paths. The software adjusts flight altitude, speed, and camera angles according to structural features such as high piers, towers, and undersides. On average, it takes only 5 minutes to plan a complete inspection route for a bridge.

This ensures full coverage of critical areas without blind spots while balancing flight safety and data integrity. Combined with rapid modeling, RIEBO enables “same-day modeling and route planning” for first-time inspections.

2. Execution: Efficient Data Acquisition and Accurate Defect Detection

(1) Single-Operator Workflow: 90 Minutes for a 500m Bridge

The inspection requires only one operator, one vehicle, and one drone system. Equipped with customized metering modes and telephoto lenses, the camera avoids underexposure in shadowed areas and ensures safe distances from structures. Following pre-planned routes, the drone automatically captures high-resolution images of the entire bridge. For a 500-meter multi-span bridge, data collection takes around 90 minutes, compared with several days using traditional methods—without disrupting traffic.

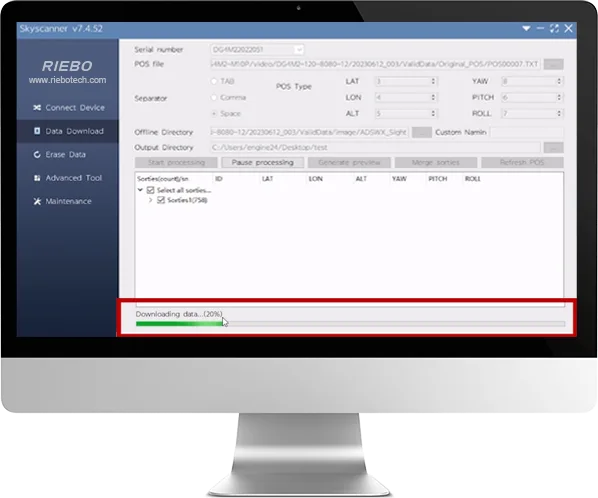

(2) Professional Data Processing

Captured images are pre-processed in Skyscanner, RIEBO’s data management software, which organizes datasets, embeds geolocation metadata, and calculates fields of view for millimeter-level defect positioning. It is also compatible with mainstream modeling software for flexibility and professional-grade results.

(3) AI + Human Verification for Defect Identification

Processed data enters RIEBO’s AI defect detection system, which uses convolutional neural networks trained on large datasets of annotated defects (cracks, weld failures, corrosion, loose bolts, etc.). The system enhances and segments images, providing pixel-level crack measurements—even under challenging conditions.

To ensure accuracy, RIEBO adopts a dual mechanism of AI pre-screening and expert verification. Engineers validate AI-marked defects within the Tongtu Intelligent Inspection Management System, ensuring both comprehensiveness and precision in defect recognition.

3. Management: Digitalized Oversight and Scientific Reporting

(1) 3D Visualization of Bridge Health

Within the Tongtu system, all verified defect data is linked to the bridge’s digital twin. Managers can view 3D bridge models, click defect points for details (e.g., crack length, corrosion area, spatial coordinates), and track changes over time. Statistical dashboards summarize defect counts, distributions, and hotspots, making decision-making more efficient.

(2) Customizable Inspection Reports

The system automatically generates custom inspection reports, including bridge details, workflows, defect lists (with 3D positions and HD images), analysis, and maintenance recommendations. Reports are digital, easy to archive and share, and reusable for long-term monitoring—solving the challenges of traditional paper-based reporting.

4. RIEBO Drone Bridge Inspection: Redefining Efficiency in Bridge Maintenance

From digital twin modeling to AI-enhanced defect detection and digitalized management, RIEBO’s solution delivers end-to-end digitalization, efficient execution, and precise identification. Its single-operator workflow reduces labor and equipment costs, centimeter-level modeling ensures accuracy, and AI plus 3D visualization improves defect detection and decision-making.

As smart infrastructure maintenance becomes a growing priority, RIEBO drone bridge inspection is emerging as a vital tool for modernizing highway asset management. With continuous advancements in big data and AI, RIEBO refines inspection workflows to deliver efficient and reliable support for safe bridge operation. If you are looking for a professional bridge inspection solution, contact us today to learn how RIEBO can help.