The Hong Kong–Zhuhai–Macao Bridge, the world’s longest sea-crossing bridge, stretches across the ocean like a colossal dragon. Beneath its roadway lie countless bridge piers, each anchored deep into the seabed. Many wonder — how can engineers build such massive foundations in the deep sea?

Let’s explore how cross-sea bridges are designed and constructed step by step.

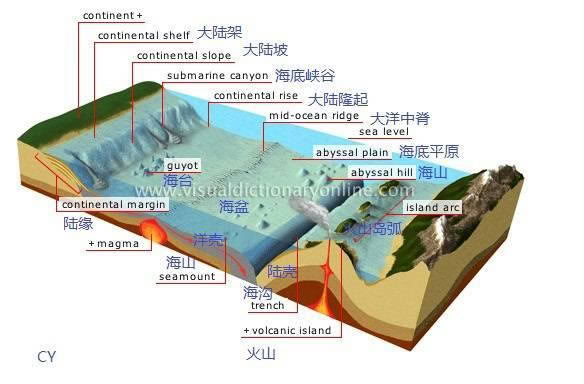

1. Understanding the Seabed Structure

Before construction begins, engineers must fully understand the complex terrain beneath the sea.

The ocean floor features mountains, ridges, trenches, plains, and deep valleys, with rock layers that vary dramatically in depth — from as shallow as 200 meters below sea level to more than 10,000 meters in deep trenches.

These layers are often covered by soft marine sediment, such as mud and silt. Since soft sediment cannot support heavy structures, bridge piers must reach solid rock layers deep below the seabed to ensure stability and prevent settlement or collapse.

2. Seabed Geological Survey

Accurate geological surveys are the foundation of marine bridge construction. Geotechnical teams conduct comprehensive seabed mapping, identifying where the seabed is shallow or deep, and determining how far the bedrock lies beneath the water surface.

The collected data is compiled into a detailed geological report, which is then used by structural engineers and designers to select the most cost-effective and structurally sound design plan for the bridge.

3. Bridge Pier Design

Designing the bridge piers is one of the most critical phases of the project. Engineers aim to minimize the length and depth of the piers while ensuring maximum structural stability and cost efficiency.

Because of this, cross-sea bridges are often not perfectly straight — their alignment follows areas with shallower seabeds, allowing easier and more economical construction. Where no shallow areas exist, engineers must design deeper foundation systems capable of withstanding massive loads and ocean currents.

Once the design is finalized, construction of the pier foundations begins.

4. Building Bridge Foundations: From Shallow to Deep Waters

Each bridge pier rests on a foundation base, called a bearing platform or pile cap. Different construction methods are used depending on water depth and seabed conditions.

(1) Cofferdam Method (for Shallow Waters)

In nearshore shallow waters, builders often use the cofferdam method.

Steel sheet piles or earthen dams are used to create an enclosed area around the planned foundation site. Water and sediment are pumped out using dewatering equipment until the seabed surface is exposed.

Workers can then build the foundation in a dry working environment, similar to land-based construction. Once completed, the steel sheets are removed.

While effective and relatively simple, this method is time-consuming and environmentally intrusive, making it suitable only for shallow water construction.

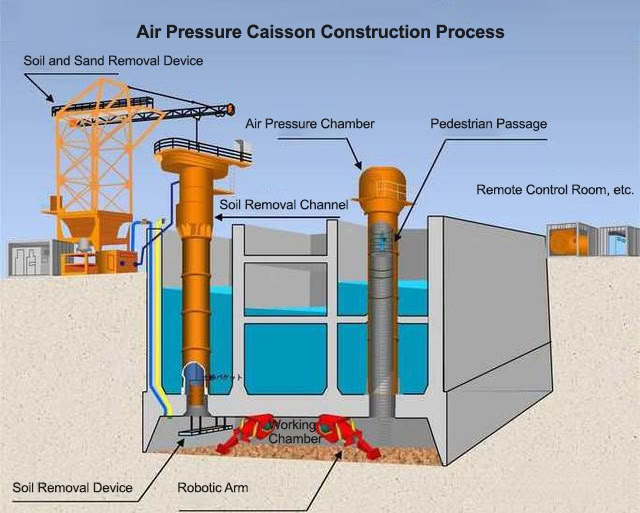

(2) Caisson Method (for Medium-Depth Waters)

When building in deeper waters, the cofferdam method becomes impractical, so engineers use the caisson method.

In this technique, large cylindrical caissons — often the size of a basketball court — are prefabricated on land and then transported by ship to the designated site.

Once positioned, concrete is poured into the caisson, causing it to sink gradually under its own weight until it reaches the designed depth. Additional sections are added as it sinks, forming a continuous shaft that reaches the seabed.

Afterward, the interior water is pumped out, and concrete is poured inside to form a solid foundation. Modern pneumatic caisson technology has replaced traditional manual excavation, using remote-controlled equipment to ensure worker safety and efficiency.

(3) Pile Driving Method (for Deep Waters)

In the deepest areas, engineers rely on the pile foundation method, the same technique used for the Hong Kong–Zhuhai–Macao Bridge.

Using heavy-duty pile-driving machinery, steel piles are hammered one by one into the seabed until they reach stable bedrock. Each deep-water pier is supported by multiple piles working together as an integrated structure, providing enormous load-bearing capacity.

This method is ideal for large-span sea-crossing bridges that must withstand strong ocean currents, waves, and wind.

5. Pier and Superstructure Construction

Once the foundations and pile caps are in place, bridge piers are assembled — usually prefabricated on land and transported to the site for installation. After the piers are secured, bearings are added, followed by the deck segments that form the roadway.

Most modern cross-sea bridges are cable-stayed or suspension bridges, using high-tension steel cables capable of bearing hundreds of tons of force. These cables enable the bridge to span long distances between piers while maintaining flexibility and strength.

6. Durability: Anti-Corrosion and Anti-Collision Measures

Every cross-sea bridge is designed with a service life of over 100 years, so corrosion and impact protection are vital.

- Engineers mix special anti-corrosion additives into concrete to resist saltwater damage.

- Steel piles and caissons are coated with protective materials to slow chemical corrosion.

- To prevent ship collisions, water-filled impact barriers are installed around pier bases, absorbing energy from accidental impacts.

7. Conclusion: Engineering Mastery Over the Sea

Building a cross-sea bridge is one of the most challenging feats of modern civil engineering.

It requires precise geotechnical investigation, innovative foundation design, and advanced construction technology to overcome the complex forces of the ocean.

These monumental structures not only connect regions and boost economies but also stand as symbols of human ingenuity in conquering the sea.

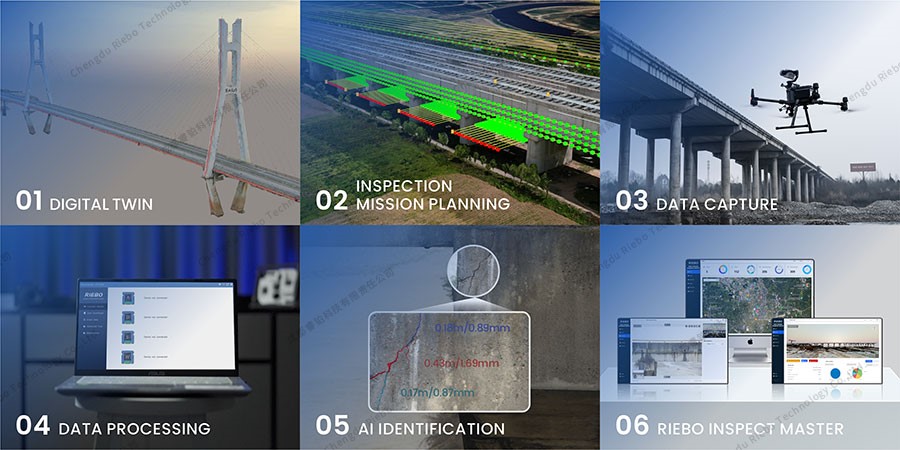

Riebo’s Drone Bridge Inspection Solution: Empowering Modern Bridge Maintenance

After completion, cross-sea bridges require regular inspection and maintenance to ensure long-term safety. This is where Riebo’s Drone Bridge Inspection Solution plays a vital role.

Equipped with high-resolution cameras and AI-powered defect recognition, Riebo’s solution can:

- Inspect bridge decks, cables, and pier surfaces in high detail,

- Detect corrosion, cracks, and damage in hard-to-reach areas,

- Monitor structural health efficiently and safely without disrupting traffic.

By integrating drone technology with digital inspection systems, Riebo enables smarter, faster, and more reliable maintenance for modern sea-crossing bridges.