Corrosion is one of the most common and destructive problems affecting bridge durability. Over time, exposure to moisture, salt, and pollution leads to the gradual degradation of steel and reinforced concrete. This not only compromises a bridge’s appearance but can also reduce its load-bearing capacity and threaten structural safety.

Understanding how bridges corrode, how to detect corrosion early, and how to prevent or repair it is essential for ensuring long-term bridge performance.

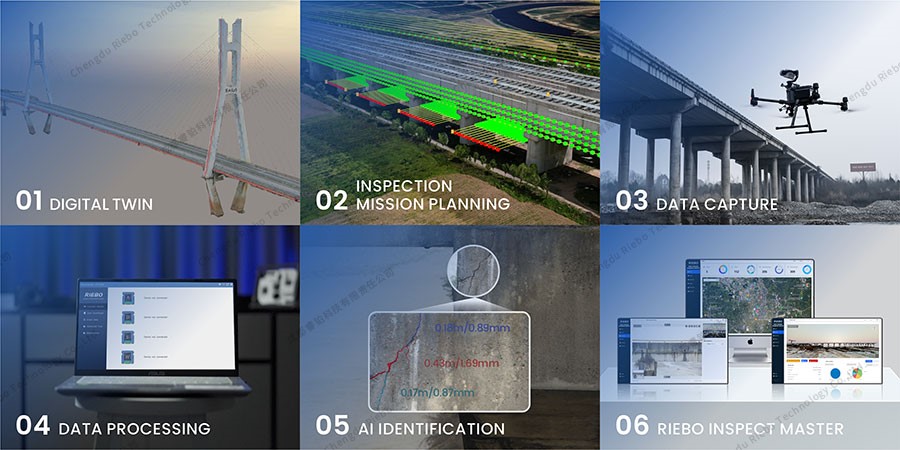

With advanced tools like Riebo’s Drone Bridge Inspection, engineers can now identify and monitor corrosion efficiently—without disrupting traffic or risking safety.

1. What Is Bridge Corrosion?

Corrosion is the chemical or electrochemical reaction between construction materials (such as steel or rebar) and their environment, leading to material loss and weakening.

In bridges, corrosion typically affects:

- Steel structures (beams, cables, towers, joints)

- Reinforcement inside concrete

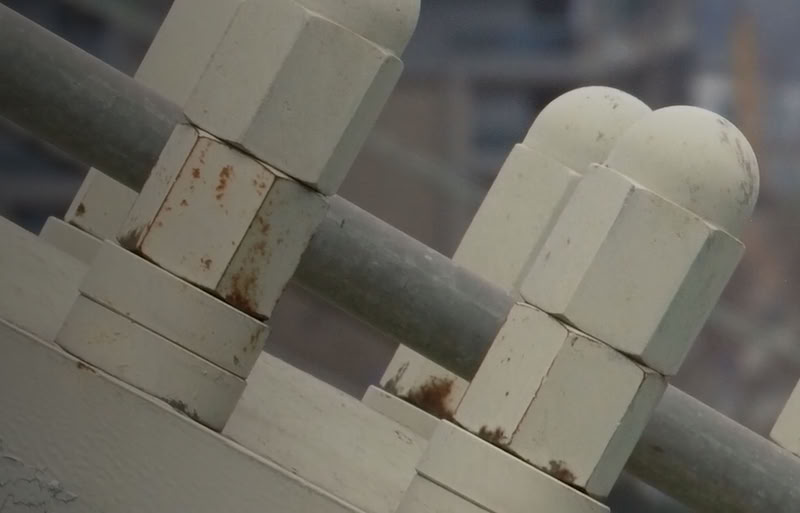

- Bearings, bolts, anchorages, and handrails

Once corrosion starts, it tends to accelerate under moisture and oxygen exposure, causing cracking, spalling, and section loss.

2. Common Types of Bridge Corrosion and Their Causes

2.1 Atmospheric Corrosion

Atmospheric corrosion occurs when moisture and oxygen in the air react with exposed steel surfaces, producing rust (iron oxides) that gradually weakens the material. This process accelerates in environments with high humidity, acid rain, salt spray, or industrial pollutants, all of which increase the rate of oxidation. It most commonly affects areas such as the underside of bridge decks, bearings, bolts, and steel connections where water or contaminants can accumulate. Over time, atmospheric corrosion leads to surface pitting, coating deterioration, and reduced fatigue strength, ultimately compromising the bridge’s durability and structural integrity.

2.2 Chloride-Induced Corrosion

Chloride-induced corrosion occurs when chloride ions penetrate the concrete surface and destroy the passive protective film surrounding the reinforcing steel. Once this film is broken, the steel reacts with water and oxygen to form rust, which expands and cracks the surrounding concrete. This process is particularly aggressive in coastal or marine environments where salt-laden air and sea spray are prevalent, as well as in regions where de-icing salts are used during winter. Because the damage develops internally, chloride corrosion often remains hidden until visible rust stains, cracks, or concrete spalling appear on the surface, making early detection and preventive maintenance essential.

2.3 Carbonation Corrosion

Carbonation corrosion results from a chemical reaction between carbon dioxide in the air and calcium hydroxide within concrete, forming calcium carbonate and gradually lowering the concrete’s alkalinity. When the pH value drops below a critical level, the protective layer around the reinforcing steel dissolves, allowing corrosion to begin. This type of corrosion progresses slowly but steadily, especially in urban environments with elevated CO₂ levels and moderate humidity. Once the depth of carbonation exceeds the concrete cover thickness, the embedded steel becomes vulnerable, leading to cracks, spalling, and long-term structural weakening.

2.4 Electrochemical Corrosion

Electrochemical corrosion occurs when different parts of a metal structure act as anodes and cathodes in the presence of moisture, creating an electrical circuit that accelerates metal dissolution at the anode. In reinforced concrete bridges, this often happens between wet and dry regions of the same steel reinforcement, forming countless tiny “microcells” of corrosion. The presence of salts, water, or pollutants intensifies the reaction, causing localized pitting and uneven material loss. Over time, electrochemical corrosion reduces cross-sectional area and weakens the bond between steel and concrete, compromising the bridge’s overall strength.

2.5 Crevice and Pitting Corrosion

Crevice and pitting corrosion are highly localized forms of deterioration that occur in confined or shielded areas of metal components. Crevice corrosion develops in narrow gaps—such as bolted joints, weld seams, or overlapping plates—where oxygen cannot circulate freely, creating a stagnant and acidic micro-environment that accelerates corrosion. Pitting corrosion, on the other hand, manifests as small but deep holes on metal surfaces, often invisible until they cause serious damage. Both types are particularly dangerous because they progress rapidly and unpredictably, leading to sudden failures even when the surrounding metal appears intact.

3. Effects of Corrosion on Bridge Structures

| Impact Type | Visible Symptoms | Consequences |

| Reduced load capacity | Section loss in steel or rebar | Weakened structure, fatigue failure |

| Concrete damage | Cracks, spalling, exposed steel | Accelerated corrosion, safety risk |

| Connection failure | Rusted bolts or welds | Loosened joints, misalignment |

| Aesthetic & safety issues | Rust stains, debris falling | Reduced durability and appearance |

4. How Drones Detect Bridge Corrosion

Traditional corrosion inspection requires scaffolding, lifts, or rope access—methods that are time-consuming and potentially dangerous. Riebo’s Drone Bridge Inspection provides a faster, safer, and more precise alternative.

Advantages of Drone Corrosion Inspection

- High-resolution imagery: Detects rust, paint peeling, and discoloration.

- Multispectral and infrared sensing: Identifies moisture infiltration and hidden corrosion.

- AI-based corrosion analysis: Classifies corrosion severity and estimates affected area.

- 3D modeling: Maps corrosion distribution across the bridge for data-driven maintenance planning.

Regular drone inspections help engineers track corrosion progression and take preventive action before serious damage occurs.

5. Corrosion Repair and Prevention Strategies

5.1 Surface Protection

Apply anti-corrosion coatings or metallic coatings (zinc, aluminum) to isolate steel from oxygen and moisture.

5.2 Cathodic Protection

Use sacrificial anodes or impressed current systems to redirect corrosion current away from structural steel.

5.3 Structural Repair

Clean corroded surfaces, remove damaged material, and replace or weld affected steel members.

For reinforced concrete, remove loose concrete, treat rusted rebar, and reapply a protective layer.

5.4 Environmental Control

Improve drainage, prevent water accumulation, and avoid direct exposure to aggressive agents like salt or chemicals.

6. Corrosion Severity and Maintenance Timing

| Corrosion Level | Typical Condition | Recommended Action |

| Mild | Local rust spots, no section loss | Cleaning + recoating |

| Moderate | 5–10% area rusted, coating failure | Partial repair + new protection |

| Severe | Exposed rebar or section thinning | Immediate strengthening or replacement |

7. Conclusion

Bridge corrosion is a slow yet relentless process driven by environmental, material, and construction factors.

By combining regular inspections, preventive maintenance, and drone-based corrosion detection, engineers can:

- Identify corrosion early

- Quantify its extent

- Apply targeted protection and repair strategies

With Riebo’s Drone Bridge Inspection, corrosion monitoring becomes faster, safer, and far more accurate—helping extend the lifespan of vital bridge infrastructure.