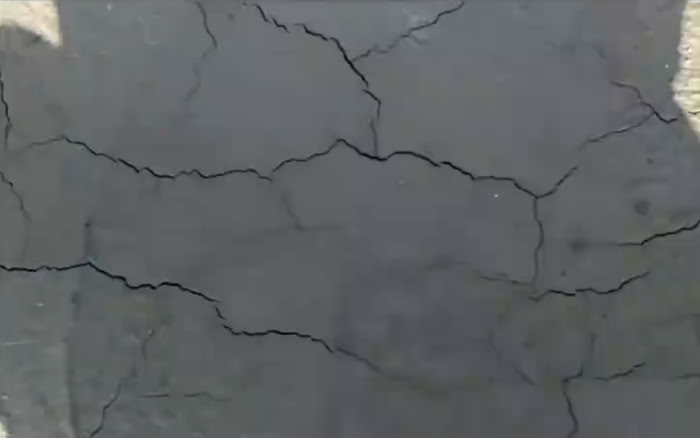

Cracks are one of the most common and concerning defects in bridge structures. While small surface cracks may seem harmless, they often indicate deeper structural or material issues that could worsen over time.

Understanding how bridge cracks form, how to detect them efficiently, and how to repair them properly is essential to maintaining bridge safety and durability.

With advanced technologies like Riebo’s Drone Bridge Inspection Solution, engineers can now detect, measure, and monitor cracks far more effectively than through traditional manual methods.

1. Main Causes of Bridge Cracks

Bridge cracks can originate from multiple sources — from load stress to material defects. Below are the most typical causes of cracking in concrete bridges.

1.1 Load-Induced Cracks

Load-induced cracks occur due to static or dynamic loads from vehicles, wind, or vibrations.

They are divided into two main types:

- Secondary stress cracks, caused by indirect or uneven stresses, often appearing as tensile or shear cracks.

- Direct stress cracks, caused by loads that directly exceed the tensile strength of the concrete.

These cracks are most common in bridge decks, girders, and piers subjected to repetitive or excessive loading.

1.2 Temperature-Induced Cracks

Concrete expands when heated and contracts when cooled. When thermal movement is restrained — for example, in long-span bridges — internal stresses build up. Once these stresses exceed the concrete’s tensile capacity, cracks appear.

Temperature-related cracks often:

- Open and close with seasonal temperature changes

- Are caused by sunlight, hydration heat, or improper cold-weather construction

1.3 Shrinkage Cracks

Shrinkage cracks are among the most common in concrete bridges. They form when the concrete volume reduces as it dries and hardens — mainly due to plastic shrinkage or drying shrinkage. Key influencing factors include:

- Cement type and content

- Aggregate size and grading

- Water-cement ratio and additives

- Curing method and environmental humidity

Improper curing or excessive water in the mix accelerates shrinkage and cracking.

1.4 Foundation Movement Cracks

Uneven settlement or horizontal movement of the bridge foundation can lead to additional stresses in the structure.

When these stresses surpass the concrete’s tensile limit, cracks develop — often diagonally through the substructure or abutments.

Common causes:

- Inaccurate geotechnical data

- Uneven soil conditions or groundwater erosion

- Differential loading or poor foundation type selection

- Frost heave, landslides, or fault movement

1.5 Reinforcement Corrosion Cracks

When the steel reinforcement inside concrete begins to rust, the rust products expand up to several times the volume of the original steel.

This expansion creates internal pressure, leading to cracks and spalling of the concrete cover.

Causes include:

- Insufficient concrete cover thickness

- Carbonation reducing alkalinity

- Chloride intrusion from de-icing salts or seawater

Once corrosion begins, it weakens the bond between steel and concrete, reduces load-bearing capacity, and accelerates further cracking.

1.6 Frost-Induced Cracks

In cold climates, water inside the concrete freezes and expands, generating internal pressure that leads to cracking.

Repeated freeze–thaw cycles are especially damaging to early-age concrete or poorly cured structures.

Over time, frost damage reduces the concrete’s strength and makes it more porous, accelerating other forms of deterioration.

1.7 Material-Quality Cracks

Poor-quality materials or improper mix design can cause microstructural weaknesses in concrete.

Issues include:

- Cement with unstable strength or high alkali content

- Aggregates with excessive clay, sulfides, or organic matter

- Contaminated mixing water or additives containing chlorides

These defects lead to excessive shrinkage, reduced strength, and long-term cracking.

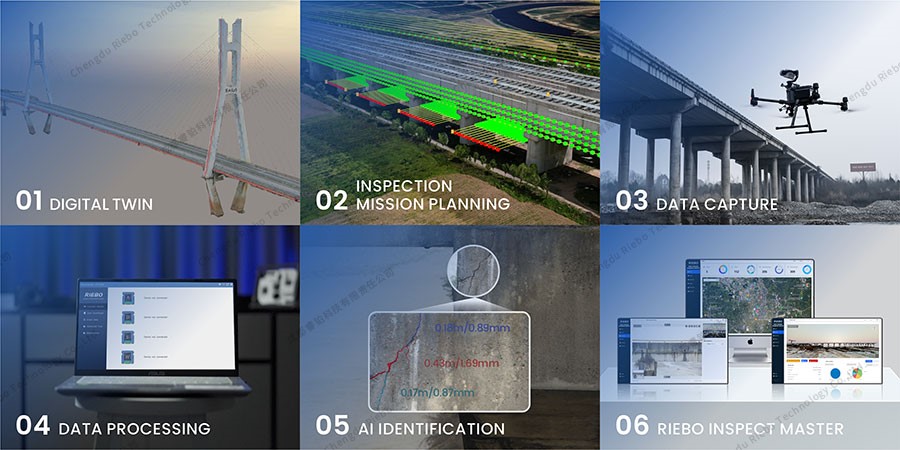

2. The Role of Drone Bridge Inspection in Crack Detection

Traditional bridge inspections require scaffolding or rope access, which can be time-consuming, costly, and risky.

Drone bridge inspection has revolutionized this process.

Advantages of Drone Crack Detection:

- High-resolution imaging captures fine cracks (even <0.2 mm wide) in hard-to-reach areas like the underside of decks or cables.

- AI-based image analysis automatically identifies, measures, and tracks crack propagation over time.

- 3D modeling provides visual mapping of crack distribution across the structure.

- Non-contact inspection avoids traffic disruption and reduces safety risks for inspectors.

By integrating drone data with engineering analysis, maintenance teams can prioritize repairs based on crack severity and development rate.

3. How Bridge Cracks Should Be Repaired

The treatment method depends on the crack type, width, and location.

Below are typical repair techniques:

3.1 Epoxy Injection for Structural Cracks

For structural cracks that penetrate deep into concrete:

- Clean the surface and seal the crack line.

- Install injection ports along the crack path.

- Inject epoxy resin from bottom to top under pressure.

- Seal and finish the surface.

This restores the concrete’s integrity and prevents water intrusion.

3.2 Surface Sealing for Fine Cracks

Hairline cracks can be sealed with a concrete protection coating:

- Clean and roughen the surface with a steel brush.

- Wash and dry the area.

- Apply primer and a thin protective coating to prevent moisture ingress.

3.3 Filling and Grouting for Wider Cracks

For wider cracks that do not affect prestress tendons:

- Cut a shallow “V-shaped” groove along the crack.

- Clean and wet the groove.

- Fill with non-shrink repair mortar or epoxy grout.

- Finish and cure the surface.

3.4 Reinforcement and Spalling Repair

For areas where rebar is exposed or concrete has spalled:

- Remove loose material and rust from steel bars.

- Weld or tie new reinforcement to strengthen the section.

- Recast the area using epoxy mortar or high-strength repair concrete.

- Apply a protective concrete cover layer.

These methods restore structural capacity and protect against future corrosion.

4. Preventive Maintenance and Monitoring

Early detection is key to preventing cracks from expanding.

Regular inspections—especially using drones—allow engineers to:

- Monitor crack growth

- Detect new defects

- Plan targeted maintenance before major repairs become necessary

Riebo’s Drone Bridge Inspection Solution enables efficient, AI-assisted monitoring that enhances maintenance decisions, saves time, and extends bridge lifespan.

Conclusion

Bridge cracks form due to a variety of factors, from load and temperature to material and environmental influences.

While some are harmless, others can rapidly develop into structural threats.

By combining engineering expertise with drone inspection technology, bridge owners can detect cracks early, understand their causes, and apply the right repair techniques to ensure long-term safety and performance.