Bridge pile foundations form the “roots” of a bridge — they transfer loads from the superstructure to the ground and ensure long-term stability. However, due to long-term exposure to groundwater, scouring, temperature variations, and vehicle loads, pile foundations often suffer from hidden damage that can gradually compromise bridge safety and durability.

This article provides a detailed analysis of common types of pile foundation damage, their causes, and effective reinforcement and maintenance methods for ensuring bridge structural integrity.

Common Types and Causes of Pile Foundation Damage

1. Uneven Settlement

Causes:

Uneven settlement occurs when the bearing capacity of the foundation soil varies significantly or when soft soil layers exist under some piles. Differences in pile length, stiffness, or construction quality can lead to unequal load distribution and result in differential settlement.

Effects:

- Tilting of bridge piers or abutments.

- Cracking at the junction between the pile cap and superstructure.

- Deck unevenness and joint misalignment.

2. Pile Cracking and Reinforcement Corrosion

Causes:

- Poor concrete quality or inadequate vibration during construction.

- Inclined or misplaced reinforcement cages leading to stress concentration.

- Insufficient concrete cover thickness, allowing water and oxygen penetration.

- Long-term chemical erosion or freeze–thaw cycles.

Effects:

Cracks develop along the pile shaft or near the pile head, exposing the reinforcement to corrosion. Over time, corrosion expands, spalling the concrete and weakening structural capacity.

3. Exposure and Spalling of Reinforcement

Causes:

When piles are subjected to prolonged water flow, carbonation, or chloride attack, the surface concrete may erode or flake off. Incomplete protective layers or poor compaction accelerate this process.

Effects:

- Exposed steel reinforcement and localized corrosion.

- Reduced durability and stiffness of the pile section.

- Possible progressive cracking along the pile body.

4. Scouring Around Pile Foundations

Causes:

Bridge piers and piles are often subjected to scouring caused by river flow, waves, or floods. Human activities such as dredging or vessel navigation can also disturb the riverbed around foundations.

Effects:

- Soil erosion and loss of lateral support.

- Exposure of pile sections and reduced bearing capacity.

- Risk of pile instability and foundation failure during floods.

5. Pile Cap and Bearing Damage

Causes:

Improper concrete placement, inadequate curing, or temperature-induced stress can cause cracking in pile caps. Long-term water exposure or dynamic vehicle loads accelerate deterioration.

Effects:

- Visible cracks or spalling in the pile cap.

- Displacement of bearings or deformation at the cap–pier connection.

- Loss of load transfer efficiency between piles and the superstructure.

Typical Repair and Reinforcement Methods

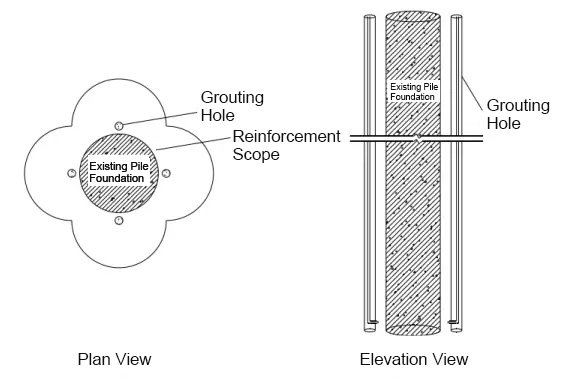

1. Grouting Reinforcement

When small cracks or internal voids appear in the pile foundation, engineers often use a grouting technique. This involves injecting a cement-based or epoxy material under pressure into the cracks. The grout fills the gaps, bonds with the surrounding concrete, and restores the pile’s overall strength.

After the grout hardens, the repaired section becomes denser, more watertight, and less likely to crack again. This method is particularly useful for piles that have minor cracking but are still structurally sound. It prevents further corrosion of the reinforcement and stops the damage from spreading.

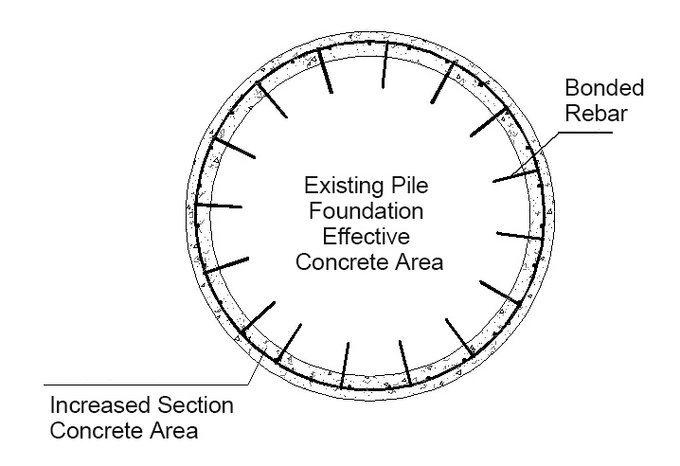

2. Concrete Encasement for Surface Protection

When the outer surface of a pile is damaged or the reinforcement becomes exposed, concrete encasement is an effective solution. In this process, a new layer of concrete or high-strength mortar is poured around the existing pile—sometimes underwater—to form a protective shell.

This shell not only restores the pile’s original diameter and load-bearing capacity but also shields the reinforcement from corrosion and water attack. For piles located in rivers or tidal zones, encasement also reduces erosion from flowing water and improves the structure’s long-term durability.

3. Ground Improvement to Control Settlement

Uneven settlement is one of the most common problems in pile foundations. It can cause bridge piers to tilt or crack. To address this, engineers strengthen the soil surrounding the piles using jet grouting or deep mixing techniques.

In simple terms, a high-pressure jet of cement slurry is injected into the soil, or a mixing tool is used to blend the soil with stabilizing materials. This creates a stronger and more uniform base under the foundation.

Once the improved soil layer forms, it can better distribute loads and prevent further differential settlement.

4. Structural Jacketing and Wrapping

For piles that have lost part of their strength due to cracking, corrosion, or impact damage, jacketing is used to provide additional support. A steel casing or a fiber-reinforced polymer (FRP) sheet is wrapped around the pile to increase stiffness and prevent further damage.

Steel jackets are common in marine environments because they resist strong water currents and impact. FRP materials, on the other hand, are lightweight and corrosion-resistant, making them suitable for long-term rehabilitation.

Both methods significantly enhance the pile’s bending capacity and protect it from environmental deterioration.

5. Anti-Corrosion and Cathodic Protection

In environments with high moisture, saltwater, or chemical exposure, steel reinforcement in piles is prone to corrosion. Cathodic protection is a method used to slow down or stop this process. It works by applying a small electrical current or attaching a “sacrificial metal” (anode) that corrodes instead of the steel reinforcement.

In addition, surface coatings, sealants, and corrosion-inhibiting admixtures can be applied to prevent water and oxygen from reaching the steel. By combining these protective systems with regular inspection, engineers can greatly extend the service life of pile foundations.

Maintenance and Inspection Practices

Regular inspection is essential to detect early-stage defects such as settlement, cracking, or scouring before they develop into major structural problems.

Inspection methods include:

- Underwater visual surveys using divers or remotely operated vehicles (ROVs).

- Non-destructive testing (NDT) such as sonic echo or cross-hole sonic logging.

- Geotechnical radar and vibration sensors for continuous monitoring.

Modern technologies now allow safer and more efficient substructure assessments. Riebo’s AI-based bridge inspection can capture high-resolution images of piers and piles, automatically identify cracks, corrosion, or deformation, and integrate results into a digital monitoring platform for preventive maintenance planning.

Conclusion

Pile foundations are critical yet often invisible components of bridge structures. Common issues such as uneven settlement, concrete cracking, reinforcement corrosion, and scouring can seriously endanger bridge safety if left unaddressed.

Through proper design, advanced reinforcement techniques, and regular inspection, engineers can significantly extend the service life of bridge foundations. By integrating AI-driven inspection, drone mapping, and digital twin visualization, Riebo helps engineers detect hidden defects early, optimize maintenance schedules, and ensure safer, more resilient bridge infrastructure.