To prevent bridge safety incidents, it is essential to adopt real-time monitoring and preventive maintenance measures that ensure safe, orderly, and stable operation. Recent large-scale bridge inspection data in Beijing’s urban area has revealed common issues such as network cracks in bridges like Wanliu Bridge and Zhimen Interchange.

In addition, many concrete bridges were found to have internal cavities, which are difficult to access and monitor directly, creating significant safety risks.

From a modern mechanics perspective, cracks are the most direct and critical indicator of internal damage and safety in concrete structures. Traditional crack detection methods rely on manual or point-based inspection, which, although accurate, cannot continuously capture information and therefore have limitations.

Fiber optic sensing technology, as one of the modern structural health monitoring methods, enables comprehensive, continuous, and efficient monitoring of both concrete and steel structures. It can detect internal and external structural damage in real time and transmit the data to a central control platform through IoT (“Internet+”) communication technologies.

This allows maintenance teams to take preventive repair measures before significant structural damage occurs, ensuring safety and reliability.

This article is based on a preventive maintenance project for an urban overpass, using a new distributed fiber optic sensing system to enhance the management and safety of city bridges, ensuring their long-term service performance and reliability.

1. System Overview

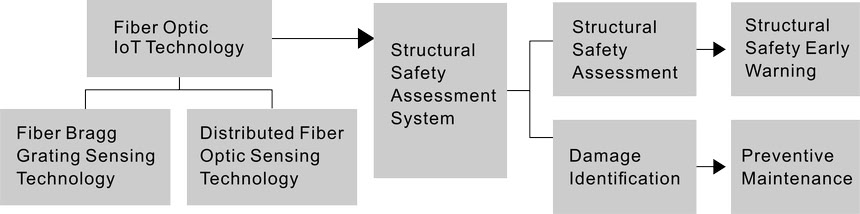

The overall system includes two main subsystems:

- Distributed fiber optic structural monitoring subsystem

- System integration and evaluation subsystem

The distributed fiber optic monitoring subsystem collects data on strain, crack distribution, and deformation trends, providing early warnings for abnormal structural behavior.

The integration and evaluation subsystem combines monitoring data from the strain and crack sensors to generate a comprehensive health assessment of the bridge.

2. Principles of Distributed Fiber Optic Strain Monitoring

Distributed fiber optic strain monitoring is a new sensing method used to measure strain across the surface of structural components. The system consists of two main parts: a demodulator and sensing optical fiber (or cable).

When pump light and probe light are injected into the optical fiber from both ends, the stimulated Brillouin scattering effect occurs. The frequency shift of the backscattered light reflects the strain at each point along the fiber. By analyzing these frequency shifts, the system can accurately determine strain distribution across the entire monitored area.

Key advantages of distributed fiber optic strain monitoring include:

- Full-distribution measurement — strain data can be obtained for any position along the sensing cable, avoiding theoretical modeling errors.

- Accurate localization — precise detection of abnormal stress zones simplifies troubleshooting.

- High consistency — single-cable bonding ensures better data uniformity than point-based sensors.

- Low cost — using standard communication cables reduces overall system expense.

- Electrical isolation — no power supply or signal collection devices are required at the sensing end, simplifying installation and improving safety.

3. Principles of Fiber Bragg Grating (FBG) Monitoring

A Fiber Bragg Grating (FBG) is a passive optical filtering component with narrow-band reflection characteristics. When light passes through the FBG, the wavelength that satisfies the Bragg condition is reflected. When the FBG is subjected to strain or temperature changes, its grating period shifts, causing a measurable change in the reflected wavelength. This property allows precise measurement of strain and temperature variations in bridge structures.

Advantages of FBG monitoring include:

- Digital sensing with long lifespan and high reliability.

- High sensitivity and measurement accuracy.

- Supports large-scale, long-distance distributed monitoring for networked data collection.

- Suitable for narrow or embedded spaces, enabling smart bridge inspection applications.

4. Technical Approach

The bridge preventive maintenance system integrates both FBG and distributed fiber optic sensing technologies. It continuously monitors strain and crack development, assesses bridge health conditions, and provides early warnings for potential risks.

The monitoring results are used to guide preventive maintenance strategies, ensuring bridge operation safety and extending structural lifespan.

5. System Features

The intelligent bridge monitoring and recognition system has the following characteristics:

- Point-based and distributed monitoring combined for comprehensive coverage.

- Integration of FBG point sensors and distributed strain sensors to capture both localized and overall structural changes.

- Full optical real-time monitoring — reliable, safe, and maintenance-free.

- No field power supply required — resistant to electromagnetic interference and lightning.

- Real-time online data acquisition and long service life.

6. Data Analysis and Preventive Actions

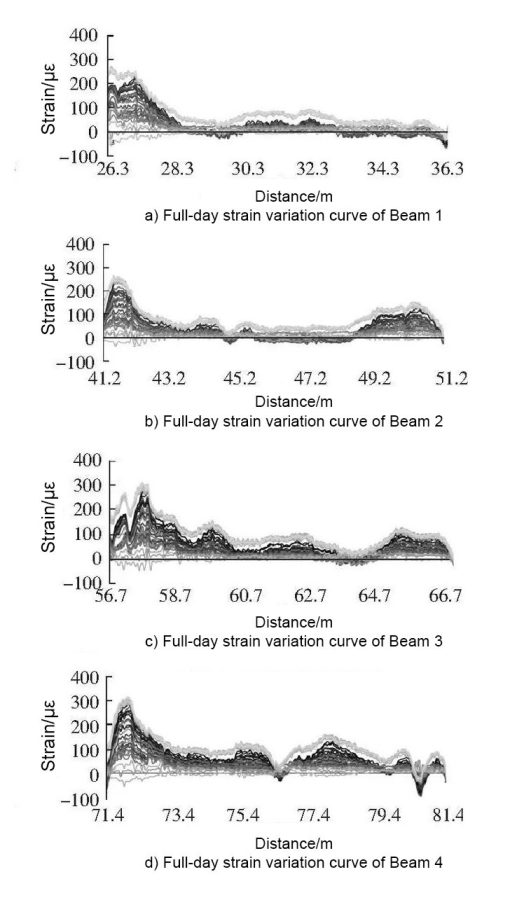

First Data Collection (June)

Measurements showed that strain variations were greater at both beam ends than at midspan, indicating that traffic loading primarily affects the beam edges.

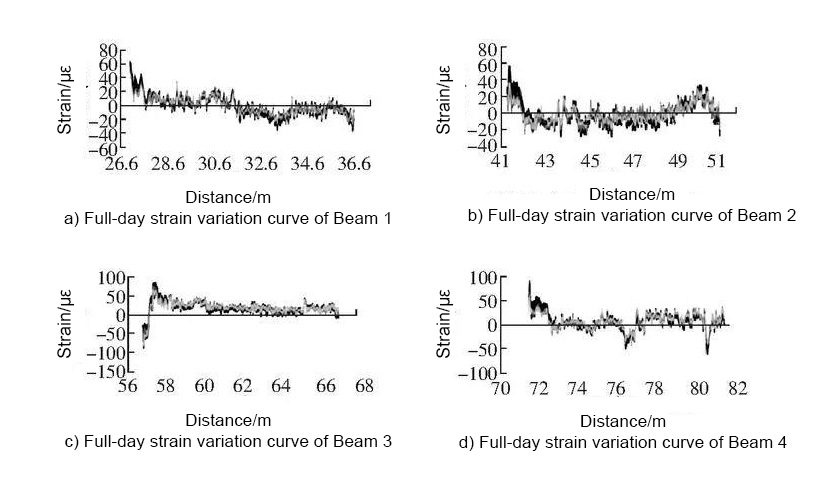

Second Data Collection (July)

Results again showed larger strain changes at beam ends, though overall variation was smaller due to mild temperature changes.

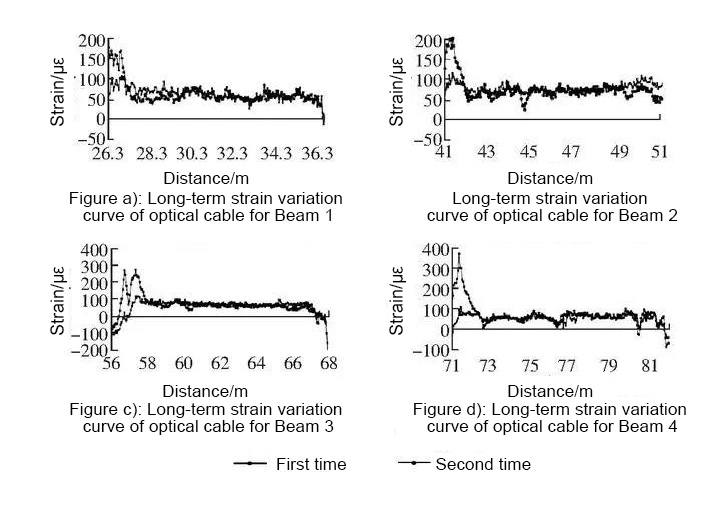

Comparative Analysis

Comparing both sets of data revealed sudden strain changes at beam ends, suggesting crack widening in these regions. Field inspections confirmed dense cracking near the beam ends, likely due to water leakage from expansion joints causing rebar corrosion.

Preventive Maintenance Plan

To address this, targeted maintenance actions were planned to slow crack development, restore beam function, and extend service life, thereby improving overall bridge performance.

7. Conclusion

This study demonstrates the practical application of fiber optic sensing technology in urban bridge preventive maintenance. By performing regular testing and analyzing collected data, engineers can locate bridge defects early and take proactive maintenance measures.

The fiber-optic IoT-based intelligent monitoring system can predict deterioration trends, extend service life, and provide valuable technical support for bridge design, construction, and management decisions.

Integration with Drone Inspection: Enhancing Bridge Monitoring

To further strengthen bridge monitoring, Riebo’s Drone Bridge Inspection Solution can be integrated with fiber optic systems. Riebo’s drones capture high-resolution imagery and 3D surface data, enabling visual validation of fiber-sensed strain or crack locations. Combined with AI-based analysis, this integration provides a comprehensive digital bridge monitoring system — merging on-surface visual data with internal fiber sensor data for faster, safer, and more accurate assessments.

Together, these technologies ensure the long-term safety, durability, and sustainability of modern bridge infrastructure.