In the field of bridge inspection, drones have become a crucial alternative to traditional manual inspections due to their efficiency, safety, and flexibility. From narrow bridge undersides to complex structures, and from visible light detection to thermal imaging analysis, different drone models, leveraging their unique technical advantages, are meeting diverse inspection needs. Below is a detailed analysis of the mainstream drones currently applicable to bridge inspection and their core performances.

Performance Analysis of Various Drone Models in Bridge Inspection

Flyability Elios 3: An Exceptional Explorer for Complex, Confined Spaces

The Flyability Elios 3 is specifically designed for narrow and complex environments. Its collision-tolerant design is a standout feature, with the fuselage encased in a robust protective frame. Even if it collides with bridge components in areas like bridge decks or cable stays, it can continue stable operation. In environments without GPS signals, it uses SLAM algorithms for precise positioning and hovering, capable of navigating through openings as small as 50x50 cm. The 180° gimbal design allows the camera to flexibly look upwards, capturing high-definition images of critical components like bridge bearings and connections at the bridge's underside. However, its battery life of approximately 12 minutes somewhat limits continuous operation time, potentially requiring frequent battery changes for larger-scale complex structural inspections.

DJI Matrice 300 RTK: A Benchmark for High-Precision Surveying and Stable Operation

The DJI Matrice 300 RTK performs exceptionally well in bridge inspection. This model boasts a flight time of up to 55 minutes. Its integrated RTK (Real-Time Kinematic) positioning technology achieves centimeter-level accuracy, providing a solid guarantee for high-precision bridge surveying and structural monitoring. The device supports operation in extreme environments from -20℃ to 50℃, coupled with a long image transmission range of up to 15 kilometers, making it particularly suitable for bridge inspection tasks in high-altitude, severe cold, and other harsh regions. The upward gimbal design allows direct capture of the bridge's underside structure, avoiding the operational risks associated with traditional drones flying inverted. Furthermore, its AI-driven automated inspection function can batch-identify similar defects, significantly reducing manual annotation workload. However, this model also has some limitations, such as its reliance on stable RTK network signals, which might be affected in some remote areas, and potential additional network costs during use.

Riebo has developed an independent navigation module that seamlessly integrates with the drone to effectively address the challenge of weak GNSS signals under bridges. This innovation ensures uninterrupted, highly accurate navigation even in areas traditionally prone to GNSS interference, leading to more reliable and comprehensive bridge inspections.

Autel Evo 2 Pro RTK: The Perfect Balance of Portability and Precision

The Autel Evo 2 Pro RTK excellently integrates lightweight design with high-precision positioning. Weighing only 1.1 kilograms, it features a centimeter-level accurate RTK positioning system. This characteristic makes it excel in rapid-response bridge inspection tasks, suitable for quick deployment in hard-to-reach areas like mountainous bridges. It is compatible with high-definition visible light cameras and thermal imaging sensors, capable of simultaneously detecting surface cracks and internal rebar corrosion in bridges. However, its single flight time is approximately 25 minutes, requiring frequent battery changes for long-distance inspections of large bridges. Additionally, its wind resistance rating of Level 6 means it might experience slight swaying in strong high-altitude air currents over bridges, affecting image acquisition stability.

Skydio 2+: A Leader in Intelligent Obstacle Avoidance and Complex Environment Adaptability

The Skydio 2+ is renowned for its advanced AI obstacle avoidance technology. By using multiple cameras to perceive the surrounding environment in real-time and leveraging algorithms to quickly analyze and plan alternative paths, it can autonomously navigate complex environments like dense pier areas, greatly enhancing flight safety. It supports 4K/60p HDR video recording, capable of clearly documenting bridge surface conditions. However, its 12.3MP camera is slightly less capable than some high-pixel professional mapping cameras for capturing subtle details like hairline cracks on bridge surfaces. The exposed navigation camera lenses used for obstacle avoidance are prone to scratches when frequently traversing narrow spaces, which can affect the accuracy of obstacle avoidance recognition.

DJI Mavic 3 Enterprise Thermal: The Preferred Model for Thermal Imaging Inspection

The outstanding feature of the DJI Mavic 3 Enterprise Thermal is its fusion of thermal and visible light dual lenses. The thermal imaging lens can quickly detect issues like voids within concrete and rebar corrosion because changes in electrical resistance in corroded rebar areas lead to temperature differences, clearly visible in thermal images. The visible light lens is used to capture details like surface cracks. This model boasts a flight time of up to 45 minutes, coupled with a 1TB SSD, allowing it to store large amounts of thermal imaging data in a single flight, meeting the data storage needs for large bridge inspections. The 56x hybrid zoom function enables remote confirmation of suspicious defect points. However, its fixed camera cannot be replaced with other types of sensors, posing some limitations in functional expansion, and the device price is relatively high, requiring a certain procurement budget.

JOUAV PH-20: An Industrial-Grade Powerhouse for Heavy Loads and Long Endurance

As a leader among industrial-grade UAVs, the JOUAV PH-20 is purpose-built for large bridge inspections. It features an impressive 75-minute flight time and an operational radius of up to 20 kilometers, allowing it to cover the entire length of large cross-river or cross-valley bridges in a single flight, significantly reducing the frequency of mid-flight battery changes. Its maximum payload capacity of up to 10 kilograms enables it to carry multiple sensors simultaneously, such as a 61-megapixel camera, a 640x512 thermal imager, LiDAR, etc., and it also includes a drop mechanism, truly achieving "one flight, multi-dimensional data acquisition." The 30x/50x hybrid zoom lens can precisely capture subtle defects like loose bolts and weld cracks, combined with AI algorithms for automatic defect identification, greatly improving inspection efficiency. Furthermore, it features an RTK/PPK dual positioning system and an IP55 dust and water resistance rating, maintaining centimeter-level positioning accuracy even in harsh weather conditions like wind and rain, ensuring the reliability of collected data. However, its large size makes it difficult to access narrow spaces like bridge undersides and dense cable-stay areas. Additionally, its professional-grade configuration results in a higher price, making it more suitable for large engineering teams or projects with long-term large bridge inspection needs.

DJI Phantom 4 / Phantom 4 Pro: A Convenient Choice for Entry-Level Inspection

The DJI Phantom 4 series is simple to operate, making it ideal for bridge inspection beginners. Its built-in practical functions like automatic return-to-home and altitude-hold cruise reduce operational difficulty and the possibility of human error. The Phantom 4 Pro's 20-megapixel camera can capture relatively obvious cracks and other defects on bridge surfaces. However, this series has a battery life of about 25 minutes and weaker wind resistance, only able to withstand Level 5 winds. During high-altitude operations over bridges, it is prone to instability due to airflow. Furthermore, it lacks RTK positioning capabilities, limiting its positioning accuracy to basic visual inspection needs and making it unsuitable for professional surveying tasks.

Voliro T: High-End Leaders in Intelligent Inspection

The Voliro T represent the high-end technical level in current drone inspection. The Voliro T features advanced AI obstacle avoidance algorithms and can achieve omnidirectional movement, intelligently planning optimal inspection paths when facing complex structures like bridge stay cables and piers. The Skydio X10, on the other hand, has optimized battery technology, extending flight time to over 40 minutes, suitable for long-distance continuous inspection tasks of large bridges. However, their high-end configurations result in expensive prices (e.g., the Skydio X10 starts at around $15,000 USD), limiting their application primarily to large engineering teams with ample budgets. Additionally, some intelligent functions rely on cloud data processing, which might affect device performance in remote areas with poor network signals.

Customized Drones: Tailored Solutions for Special Requirements

For bridges with special structures, such as large-span arch bridges or complex steel truss bridges, customized drones demonstrate unique advantages through modular design. They can be flexibly equipped with various sensors according to inspection needs, such as magnetometers to detect stress concentration in bridge steel structures or integrated acoustic sensors to assess concrete compactness. Moreover, customized software supports integration with BIM (Building Information Modeling) systems, enabling automated integration and analysis of inspection data. However, customized drones have longer research and development cycles, typically taking 3-6 months, and higher maintenance costs due to the specialized components and calibration required. Thus, they are only suitable for projects with special and clearly defined inspection needs.

Technical Process and Key Stages of Drone Bridge Inspection

Data Acquisition: Multi-Source Perception for Comprehensive Bridge Information

Data acquisition is the fundamental stage of drone bridge inspection, requiring the comprehensive application of various technical means to obtain complete and precise bridge data. For basic data acquisition, the M300 RTK paired with a visible light camera and LiDAR is often selected as the operational equipment, capable of simultaneously collecting LiDAR point cloud data and visible light image data. Coupled with professional inspection flight planning software, such as AeroMapPro, it can precisely fit the external contours of the structure to be measured, collecting high-definition images up to millimeter-level accuracy, thereby accurately restoring the coordinates and fine shape structure of the object.

Simultaneously, oblique photography technology, leveraging multi-rotor UAVs (like DJI M300 RTK) equipped with five-lens cameras, captures images of the bridge from different angles, ensuring comprehensive coverage of critical components like bridge decks, piers, and cable stays. LiDAR scanning is suitable for complex structural bridges, capable of penetrating vegetation to obtain millimeter-level accurate point cloud data, providing a high-precision foundation for subsequent analysis. Infrared thermal imaging technology assists in detecting internal bridge defects, such as concrete voids and rebar corrosion. Close-range photogrammetry targets bridge details like cracks and bolts for close-up shooting, further improving model accuracy. During data acquisition, strict control of heading overlap (≥70%) and side overlap (≥65%) is necessary to ensure image stitching quality. Concurrently, RTK/PPK positioning technology is utilized to improve image georeferencing accuracy, reducing post-model stitching errors.

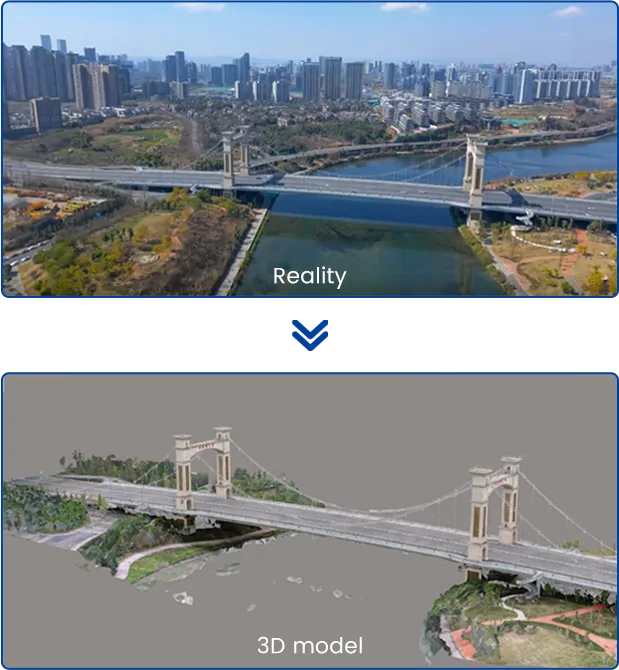

3D Modeling: Building a Bridge Digital Twin for Visual Analysis

The collected data needs to be processed by professional software to generate 3D models usable for flight planning and defect analysis. Real-scene 3D reconstruction often uses software like ContextCapture, Pix4D, or DJI SmartMap for point cloud generation and Mesh modeling, combined with BIM (Building Information Modeling) software like CATIA or Revit to further enhance structural details. The generated model must include key structural points, such as bridge piers, and cable stay anchorage zones, to facilitate subsequent flight planning. The model format should support OBJ, FBX, or LAS, to be compatible with mainstream flight planning software. Through LiDAR point clouds + digital twin 3D modeling, defects like cracks can be intuitively displayed on the model, enabling visualization of inspection results and providing an intuitive basis for subsequent analysis.

Route Planning: Ensuring Efficient and Safe Inspections Based on Structural Characteristics

Drone flight path planning must be closely integrated with the bridge's structural characteristics to ensure full coverage, high efficiency, and obstacle avoidance safety. Intelligent route generation methods can use Poisson disk sampling + viewpoint optimization to sample the 3D model surface to generate observation points and optimize shooting angles based on reconstructability rules (intersection angle, resolution). Simultaneously, the bridge is divided into different areas, such as deck, piers, cable stays, etc., with separate flight paths planned for each. Layered clustering is used to adjust flight strategies for different heights, such as close-range circling for suspension bridge main cables. In terms of flight planning software, RIEBO AeroMapPro is suitable for various bridge inspection types, as it generates flight paths that conform to the bridge's 3D model. During flight planning, no-fly zones, such as high-voltage lines and bridge towers, must be avoided, and adaptive flight speed should be employed, reducing speed in complex areas to improve imaging quality. Different types of bridges require differentiated flight planning schemes, such as helical ascent routes for cable-stayed bridges to cover cable stays, parallel tracking routes for suspension bridge main cable inspection, and serpentine routes for box girder bridge bottoms.

Defect Identification and Analysis: Intelligent Algorithms Aid in Precise Bridge Condition Assessment

By utilizing edge computing AI intelligent recognition algorithms for cloud computing and artificial intelligence analysis of inspection data, real-time qualitative analysis of various types of bridge surface defects can be achieved. By establishing a defect feature database, algorithms can quickly and accurately identify defects such as concrete spalling, rebar corrosion, and crack propagation, and quantitatively mark the size and location of various defects. For example, analysis of thermal imaging data can quickly identify areas with abnormal temperatures due to rebar corrosion; processing of visible light images can precisely measure crack width and length. Simultaneously, the data cloud platform can establish a bridge defect database, supporting comparison of multiple inspection results and tracking the evolution trend of bridge defects, providing scientific basis for bridge maintenance decisions.

Practical Application Effects and Case Studies of Drone Bridge Inspection

In the inspection work of the Xijiang Grand Bridge in Guangdong, China, the introduced drone bridge maintenance inspection system demonstrated significant advantages. This grand bridge, with a total length of approximately 2.7 kilometers and a main bridge length of 886 meters, has a towering structure where some defects are prone to occur in high or hidden areas. Traditional inspection methods were inefficient, high-risk, and had many blind spots. However, drones equipped with high-definition cameras, infrared thermal imagers, and LiDAR, combined with the Beidou GMDSS system, can precisely cover high-altitude and high-risk areas such as submerged bridge piers, main towers, and cable stays. Inspection tasks that previously took 2 to 3 days can now be completed in just 6-7 hours, greatly reducing manual workload. The system can clearly capture hidden defects like surface cracks, rebar corrosion, and concrete spalling, with data transmitted in real-time. Each flight is equivalent to a precise full-body "CT scan" of the bridge's main structure, capable of accurately identifying even 2-millimeter fine cracks, achieving a full-chain closed loop of "detection - analysis - maintenance."

RIEBO's developed drone intelligent bridge inspection system has been widely applied in bridge inspections across Sichuan, Guangdong, Anhui, and other regions. This system integrates various advanced technologies such as flight control, sensors, information science, and artificial intelligence, featuring functions like flight positioning, automatic identification, and intelligent data processing. In mountainous regions, it solves the challenge mainstream drones face—unstable flight in GPS-denied environments—and enables fully intelligent detection, analysis, and response to bridge defects. Through this system, not only has inspection efficiency been improved and safety risks reduced, but also the human and material costs associated with manual inspection have been cut, providing a leading integrated solution for bridge inspection: "intelligent control flight for fieldwork + intelligent data acquisition + intelligent scientific analysis" using drones.

Summary and Outlook

Different types of drones have their unique strengths in bridge inspection. In practical applications, the appropriate drone model and supporting technical solution should be comprehensively considered based on factors such as bridge type (e.g., beam bridge, arch bridge, cable-stayed bridge), inspection requirements (e.g., surface visual inspection, internal defects, high-precision surveying), and operational environment (wind speed, space size, weather conditions) to maximize the efficiency and quality of bridge inspection.

Looking ahead, with innovations in battery technology, drone endurance will be further enhanced; sensor accuracy and functionality will continue to be optimized, enabling more precise and comprehensive defect detection; AI algorithms will become even smarter, capable of automatically processing and analyzing vast amounts of inspection data, providing more scientific and timely decision-making advice for bridge maintenance. Drone bridge inspection technology will continue to advance towards intelligence, automation, and integration, playing an increasingly important role in ensuring bridge structural safety, extending bridge service life, and elevating bridge maintenance management to new heights.