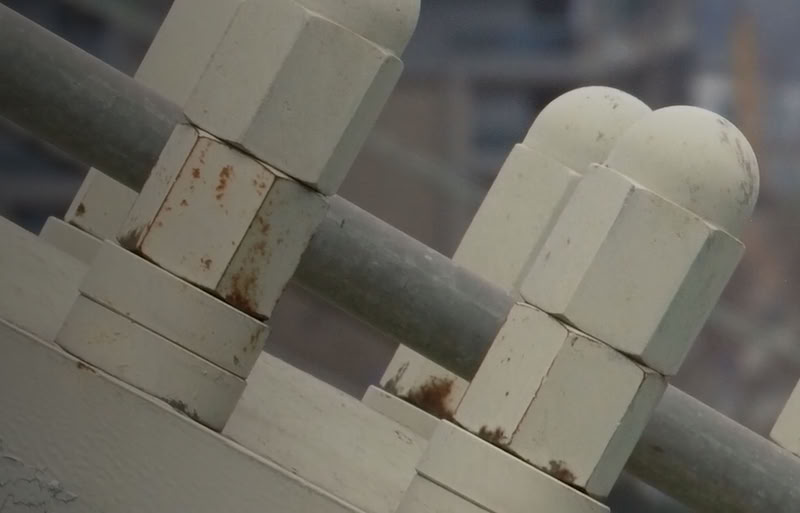

Why Coastal Bridges Face Serious Corrosion Challenges

Coastal and sea-crossing bridges face one of the toughest environmental challenges in civil engineering. Constant exposure to salt spray, humidity, ultraviolet radiation, and wind load accelerates corrosion on steel components and damages concrete surfaces. Over time, this can weaken the structure, shorten its service life, and increase maintenance costs.

Traditional inspection methods rely heavily on manual labor — rope access, scaffolding, or hanging platforms. These approaches are not only time-consuming and expensive but also pose significant safety risks to inspectors. Moreover, they often fail to capture small, early-stage corrosion spots that can develop into major structural problems.

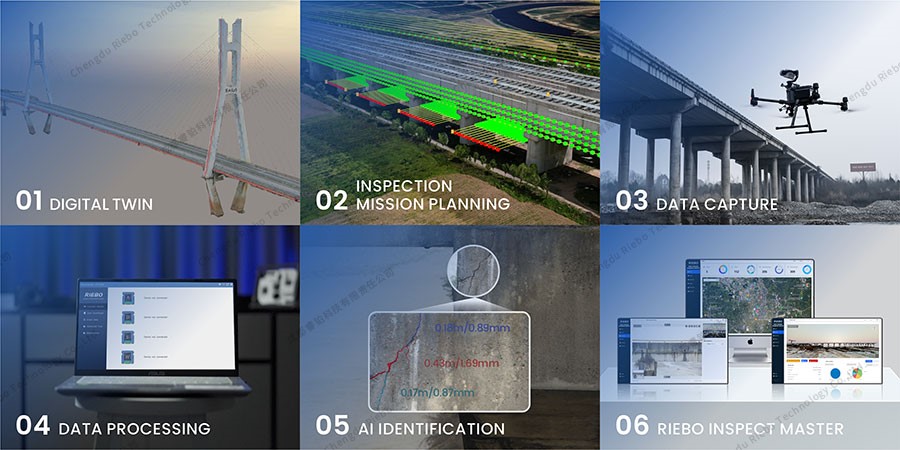

How Drones Simplify Corrosion Inspection on Coastal Bridges

1. Accessing Hard-to-Reach Areas

Drones can fly close to cables, towers, beams, and undersides of sea-crossing bridges where manual inspection is difficult or impossible. Even in strong coastal winds, the drones maintain stable flight and capture precise visual data.

2. High-Resolution Imaging for Surface Corrosion Detection

Equipped with 4K/8K cameras and zoom lenses, Riebo’s drone bridge inspection solution provides detailed close-up images of the bridge surface. These images reveal early-stage rust, coating peeling, and minor cracks, allowing maintenance teams to plan timely repairs.

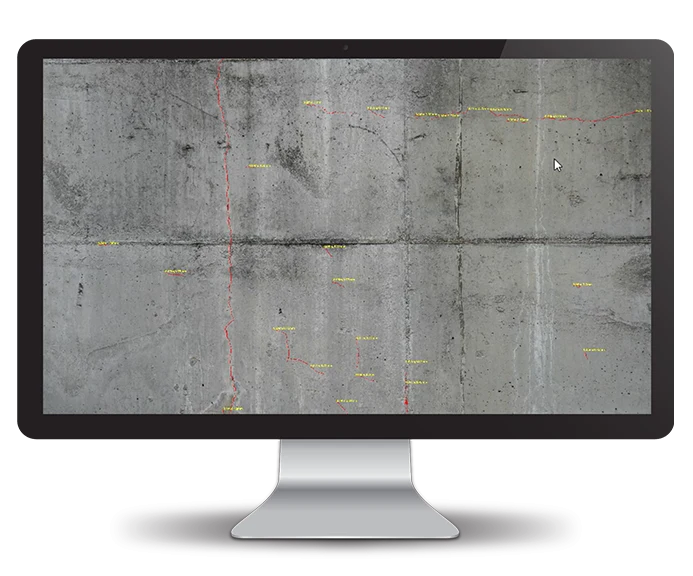

3. AI-Powered Damage Recognition

The system integrates AI image recognition algorithms that automatically detect corrosion, classify damage types, and highlight risk zones. This reduces the workload of engineers and ensures consistent, objective inspection results.

4. Safe and Cost-Effective Operation

By replacing manual inspection with drone-based observation, Riebo significantly reduces inspection time and labor costs. The process minimizes the need for scaffolding or temporary closures, and most importantly, eliminates high-altitude working risks for personnel.

5. Data Visualization and Reporting

All inspection data can be automatically compiled into digital 3D models, heat maps, and condition reports. Engineers can review corrosion distribution, compare changes over time, and integrate results into a Bridge Management System (BMS) for predictive maintenance planning.

Case Example — Drone Inspection on a Sea-Crossing Bridge

In a recent project on a coastal bridge in Southeast China, Riebo’s drone system conducted a full corrosion inspection of the steel box girder and cable areas.

Within two hours, the drones collected over 5,000 high-resolution images, identifying several corrosion spots and coating defects along the cable connections and anchor points.

Compared with traditional rope-access inspection, the efficiency improved by over 70%, and the corrosion detection accuracy increased significantly. The inspection report provided actionable data for maintenance teams to prioritize coating repair and anti-corrosion reinforcement.

Why Choose Riebo’s Drone Bridge Inspection Solution

- Stable Flight Performance in Marine Environments — Optimized propulsion and wind-resistance design ensure reliable operation near coastal bridges.

- AI-Driven Corrosion Analytics — Automated corrosion identification powered by deep learning algorithms.

- Compatible with BIM and Digital Twin Systems — Supports integration into existing infrastructure asset management workflows.

- Comprehensive Service Support — From flight planning to post-processing and data interpretation, Riebo provides end-to-end inspection solutions for global clients.

The Future of Drone-Based Corrosion Inspection

As corrosion continues to threaten marine infrastructure, drone-based inspection is rapidly becoming the preferred approach for bridge owners and maintenance teams worldwide. With advancements in AI, cloud computing, and 3D modeling, future inspections will evolve from visual observation to predictive, data-driven maintenance.

Riebo is committed to advancing this transformation by combining intelligent drones, high-resolution sensors, and AI analytics to ensure safer and more efficient bridge management.

Conclusion

Riebo’s Drone Bridge Inspection Solution provides a smarter and safer way to monitor corrosion on coastal and sea-crossing bridges.

By integrating high-resolution imaging, AI-based analysis, and digital reporting, Riebo enables engineers to detect corrosion early, reduce maintenance costs, and extend the service life of critical marine infrastructure.

With Riebo, corrosion inspection becomes faster, safer, and smarter.