Suspension bridges, with their long spans and high cables, are engineering marvels—but inspecting them has always been a challenge. Cables, anchorages, and high-altitude sections are difficult and risky to access. To ensure safety and reliability, engineers increasingly rely on advanced technologies such as cable-climbing robots and drones.

Both methods bring innovation to bridge maintenance, yet they serve different purposes. Let’s explore what each can do, their advantages and limitations, and why drones are becoming a vital tool for modern suspension bridge inspection.

Cable-Climbing Robots: Precise but Limited in Flexibility

Cable-climbing robots are designed to move along suspension bridge cables, equipped with cameras, laser scanners, or ultrasonic sensors. They offer high-precision, close-contact inspection of critical components such as:

- Main cables and stay cables

- Anchorage zones

- Cable clamps and sockets

- Corrosion and surface damage detection

Advantages:

- Extremely stable data collection due to fixed contact with cables

- High-resolution close-up imaging and sensor measurements

- Suitable for long-term monitoring of the same cable section

Limitations:

- Deployment is complex and time-consuming

- Heavy equipment requires additional setup structures

- Limited coverage (only cables, not decks or towers)

- High maintenance cost and safety risk during installation

Drones: Flexible, Efficient, and Intelligent

Modern UAVs, equipped with high-resolution cameras, LiDAR, and AI analysis, have redefined how engineers inspect large suspension bridges. Drones can quickly scan the entire bridge structure—from towers and decks to suspension cables—without interrupting traffic.

What drones can inspect:

- Bridge towers and pylons

- Deck surfaces and expansion joints

- Cable clamps, suspenders, and tower anchorage zones

- Cable corrosion and crack detection through AI image recognition

Advantages:

- Non-contact, safe operation even in high-altitude environments

- Rapid data collection and large coverage area

- Cost-effective and easily repeatable inspections

- Integrated with AI defect recognition and digital twin modeling

Limitations:

- Harder to capture extremely fine surface data (e.g., microscopic corrosion)

- Weather and wind conditions can affect flight performance

Can Drones Replace Cable-Climbing Robots?

In most cases, drones cannot completely replace cable-climbing robots, especially when microscopic or tactile measurements are required (e.g., ultrasonic testing or contact-based corrosion analysis).

However, drones can perform 80–90% of routine visual inspections, making them ideal for:

- Early-stage defect detection

- Regular visual surveys

- Follow-up comparison with digital twins

In many bridge management systems, drones are used as the first inspection layer, identifying suspicious areas for more detailed follow-up by robots or manual inspection teams.

Riebo’s Drone Bridge Inspection Solution for Suspension Bridges

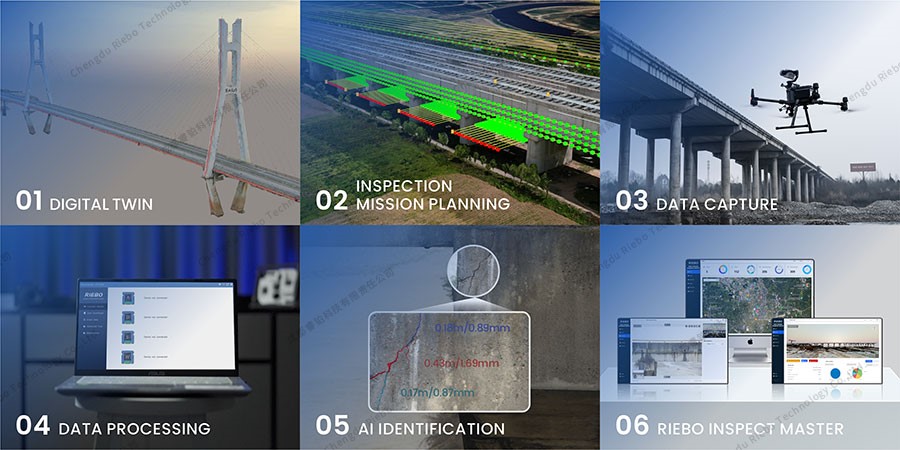

Riebo’s Drone Bridge Inspection Solution combines UAVs, AI image analysis, and digital twin technology to create a complete, data-driven inspection workflow for suspension bridges.

Key features include:

- Autonomous flight planning for complex bridge structures

- High-resolution imaging for cables, towers, and decks

- AI-powered defect detection of cracks, rust, and surface wear

- 3D digital twin management platform for visual comparison and report generation

By integrating all inspection data into an intelligent management system, Riebo’s solution helps engineers monitor changes over time, improve maintenance planning, and reduce overall inspection costs.

Conclusion

Both cable-climbing robots and drones play vital roles in suspension bridge inspection. Robots excel in precision and contact-based sensing, while drones lead in efficiency, safety, and data integration.

As inspection technology evolves, the combination of AI-driven drones and robotic sensors will enable more comprehensive and intelligent bridge management. With Riebo’s Drone Bridge Inspection Solution, engineers can achieve safer, faster, and smarter inspection for every type of suspension bridge.