The rapid development of drone technology has brought a revolutionary change to bridge inspection and maintenance. Traditional bridge inspection requires extensive time, manpower, and cost — often involving dangerous high-altitude operations. In contrast, drones enable engineers to complete inspections more efficiently, safely, and with higher accuracy, providing high-resolution imagery and comprehensive structural data in a fraction of the time.

This article introduces Riebo’s drone-based bridge inspection solution, highlighting its working principles, workflow, advantages, and practical applications in modern bridge management.

1. Principles and Workflow of Drone Bridge Inspection

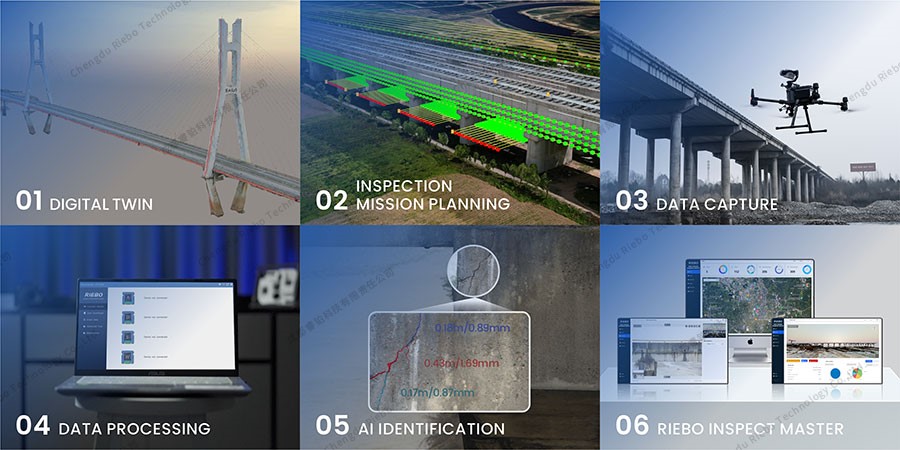

Drone bridge inspection relies on unmanned aerial vehicles equipped with high-resolution cameras, LiDAR scanners, or other sensors. By combining these payloads with RTK high-precision positioning systems, drones can capture full-view, high-definition imagery and 3D data of bridge structures.

1.1 Mission Planning

Before the flight, engineers define the inspection scope, flight altitude, and path planning. Safety procedures and risk control strategies are also established to ensure smooth and secure operations.

1.2 Pre-Flight Preparation

Before the mission, drones undergo equipment checks, battery inspection, and system calibration. RTK positioning is verified to guarantee accurate image georeferencing during flight.

1.3 Flight Execution

During operation, the drone follows the pre-set flight route to inspect bridge components such as decks, girders, piers, and cables. Onboard cameras capture high-resolution photos and videos, while LiDAR or optical sensors collect precise 3D point cloud data for structural analysis.

1.4 Data Processing and AI-Powered Analysis

After flight completion, all captured data is processed and analyzed.

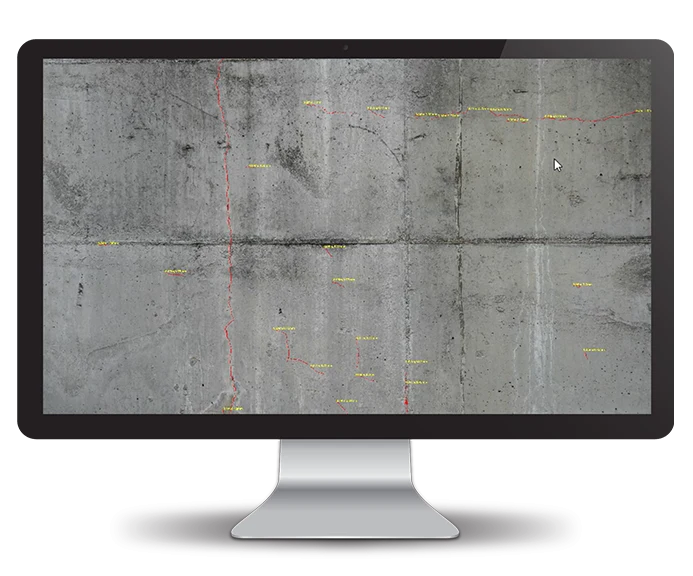

Riebo’s drone bridge inspection solution integrates AI-powered image processing to automatically detect defects such as cracks, corrosion, deformation, or spalling. The system helps engineers assess structural integrity and safety in real time.

Additionally, Riebo’s digital bridge management platform supports advanced features such as:

- Defect visualization directly on the 3D bridge model

- Historical data comparison and defect tracing

- Automated inspection reporting and cloud-based storage

This digital workflow enables more intelligent and efficient bridge lifecycle management.

2. Advantages of Drone-Based Bridge Inspection

2.1 High Efficiency

Compared with traditional manual inspection, drone-based inspection significantly reduces time and labor costs. With fast flight speeds and high-resolution imaging, engineers can quickly identify structural issues across large spans and hard-to-reach areas.

2.2 Enhanced Safety

By replacing manual climbing and scaffolding operations, drones minimize the need for personnel to work at dangerous heights, reducing potential safety risks and accidents.

2.3 Comprehensive Coverage

Drones provide a complete aerial and side-view perspective of the entire bridge. High-definition photos and 3D data help detect subtle cracks, corrosion, or internal defects that might be missed in traditional inspections.

2.4 Cost-Effectiveness

Drone-based bridge inspection reduces the need for heavy equipment, scaffolding, and manpower. The overall inspection cost is significantly lower while maintaining higher precision and reliability.

3. Applications of Drone Bridge Inspection

3.1 Bridge Condition Assessment

Drone inspection provides detailed structural imagery and 3D data to assess the bridge’s health condition. Engineers can accurately evaluate damage, deformation, or material aging, providing scientific data for repair and maintenance planning.

3.2 Disaster Damage Evaluation

After natural disasters or accidents (such as earthquakes, floods, or vehicle impacts), drones can rapidly fly over damaged bridges, capturing images and 3D models for damage assessment. This supports emergency decision-making and timely restoration.

3.3 Routine Maintenance and Monitoring

Riebo’s drone inspection system supports periodic monitoring of bridges to identify early-stage deterioration or fatigue. Continuous monitoring helps extend service life and maintain long-term operational safety.

4. Conclusion

Drone-based bridge inspection represents the future of intelligent infrastructure monitoring. With advantages in efficiency, safety, comprehensiveness, and cost, drones can replace or complement traditional inspection methods, offering engineers a more precise and data-driven approach.

Riebo’s Drone Bridge Inspection Solution integrates UAV photogrammetry, AI defect recognition, and digital twin management to achieve full-cycle bridge monitoring — from inspection to analysis and maintenance.

As drone, AI, and data processing technologies continue to evolve, UAV-based bridge inspection will become a core part of modern bridge engineering and asset management, promoting safer, smarter, and more sustainable infrastructure worldwide.