Reinforced concrete (RC) and prestressed concrete (PC) continuous slab bridges are widely used in urban overpasses, pedestrian bridges, and short- to medium-span highway structures.

They typically feature solid or hollow slab sections constructed by cast-in-place methods, with spans under 20 meters for RC slabs and slightly longer for prestressed concrete slabs—often designed with post-tensioning systems in either constant or variable-depth configurations.

Although structurally simple and efficient, continuous slab bridges are prone to several types of cracking and deformation over time due to long-term loading, material aging, or environmental effects. This article analyzes their common structural problems, reinforcement techniques, and how RIEBO provides intelligent inspection and strengthening solutions to improve bridge safety and longevity.

Common Structural Problems

(1) Vertical Flexural Cracks at Midspan

At the bottom of the slab near midspan, multiple vertical cracks may appear and sometimes extend transversely across the width. These are typical bending cracks, indicating insufficient flexural capacity under dead and live loads.

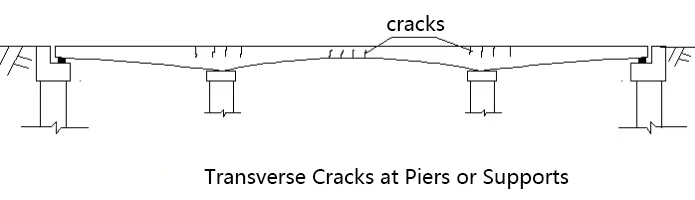

(2) Transverse Cracks at Piers or Supports

At the top surface of the slab above piers, cracks often appear across the deck, accompanied by water leakage through the slab.

These cracks are caused by excessive negative bending moments or uneven settlement of supports, suggesting that the section’s tensile capacity is insufficient in the negative moment region.

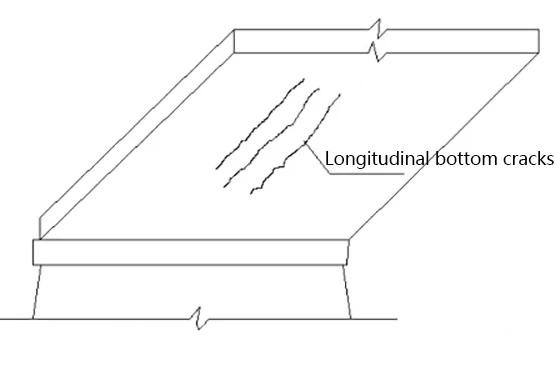

(3) Longitudinal Cracks at Midspan

Longitudinal cracks appearing at the bottom of the slab are often caused by inadequate transverse reinforcement, insufficient cover over steel or tendons, or localized tensile stress around prestressing ducts. In some cases, additives or corrosion in reinforcement accelerate crack propagation along the steel direction.

(4) Excessive Midspan Deflection

When the slab exhibits noticeable downward sagging, it usually indicates insufficient prestress or reduced stiffness due to excessive cracking in the tension zone.

Reinforcement and Strengthening Methods

(1) Steel Plate or FRP Strengthening

For flexural or longitudinal cracks exceeding code limits, bonded steel plate or CFRP (Carbon Fiber Reinforced Polymer) strengthening can effectively restore flexural stiffness and bearing capacity.

This method is lightweight, fast to apply, and widely used for the underside of slabs.

(2) Reinforcement of Negative Moment Zones

For cracks at pier tops, additional tensile reinforcement (ordinary or prestressed steel) can be embedded within the overlay of the deck at negative moment zones to increase flexural resistance at supports.

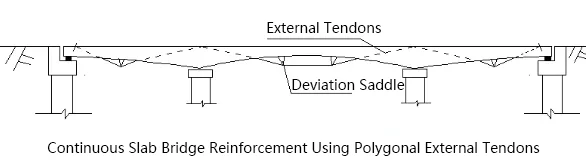

(3) Prestressing Retrofit

External or additional prestressing can be applied using deflection pulleys and deviator brackets beneath the slab, creating a polygonal tendon profile.

This approach is highly effective for multiple damage types, including flexural cracking, excessive deflection, and insufficient original prestress.

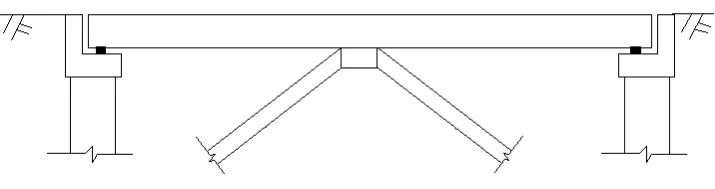

(4) Structural System Modification

In cases of large deflection or insufficient stiffness, adding inclined struts or supports near the midspan can help redistribute internal forces and reduce sagging.

However, reinforcement in the negative moment region above supports must be strengthened accordingly to ensure the system’s new equilibrium.

RIEBO’s Intelligent Bridge Inspection and Reinforcement Solutions

RIEBO Tech provides a full suite of intelligent inspection and structural strengthening advices tailored for different bridges:

- Drone + AI Visual Inspection – High-resolution UAVs automatically identify cracks, spalling, and corrosion on the beam soffit, webs, and anchorage zones.

- Digital Twin Modeling – Converts inspection data into a 3D structural model for visualization, analysis, and defect progression prediction.

- Customized Strengthening Design – Provides detailed reinforcement plans such as CFRP strengthening, external prestressing, or beam replacement based on inspection data.

- Lifecycle Health Management – From inspection to post-reinforcement monitoring, RIEBO builds a comprehensive digital health record for each bridge, optimizing long-term maintenance and safety.

Conclusion

Continuous slab bridges are efficient and widely adopted in urban infrastructure, but over time, they face challenges such as cracking, deflection, and stiffness degradation.

Through precise inspection, structural assessment, and modern reinforcement methods, their service performance can be effectively restored and extended.

With RIEBO’s intelligent UAV inspection, AI analysis, and professional strengthening technologies, bridge managers can ensure early detection of defects, implement targeted reinforcement, and achieve safer, longer-lasting, and more resilient bridge assets.