With their advantages in long-span adaptability, structural stability, and cost efficiency, suspension bridges have become the core bridge type for crossing rivers, seas, and mountainous valleys worldwide. As of 2025, more than 30 suspension bridges with main spans over 1,000 meters have been completed globally. China leads the world with more than 15 such bridges, while iconic kilometer-class suspension bridges also exist in the United States (San Francisco–Oakland Bay Bridge East Span), the United Kingdom (Humber Bridge), and Japan (Akashi Kaikyō Bridge).

However, due to differences in regional climates (such as high humidity, strong salt spray, or extreme temperature fluctuations), changes in traffic loads (increasing prevalence of heavy trucks), and extended service life, suspension bridges across the globe face common risks of structural deterioration. Establishing inspection and maintenance systems adapted to regional conditions has become essential to ensure the safety of the global transportation network.

Commonalities and Regional Characteristics of Global Suspension Bridge Defects

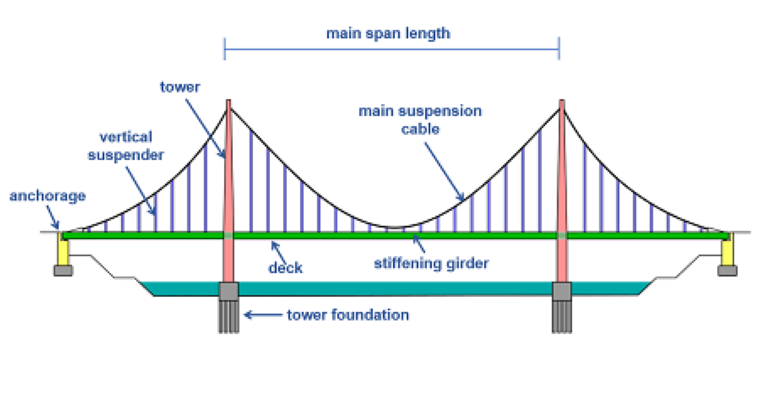

The key structural components of suspension bridges include the main cable, hangers, anchorages, towers, and stiffening girders. Their defects exhibit both structural commonality and regional individuality, with significant differences in occurrence and progression rates depending on climate and operating conditions.

Common Defects of Core Components

1. Main Cable Corrosion as the “Invisible Killer”

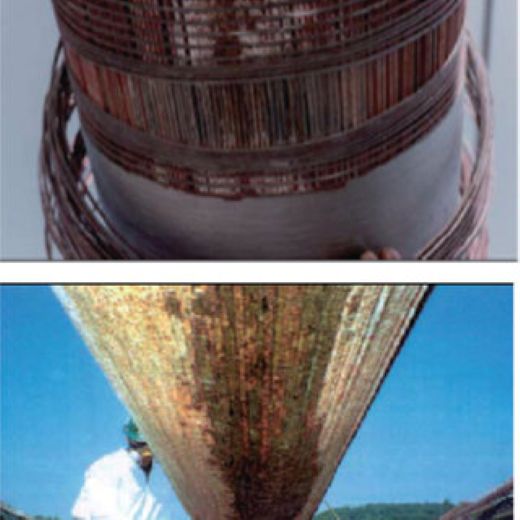

The main cable, often described as the “backbone” of a suspension bridge, is made up of multiple strands of galvanized steel wires (a typical design includes 110 strands per cable, each strand containing 127 wires of 5.2 mm diameter). With an inherent void ratio of 15–20%, these cables are prone to moisture retention, making corrosion the most universal threat to suspension bridges.

- Moisture pathways: rainwater intrusion during cable spinning, later sealed by anticorrosion wrapping; coating cracks and clamp slippage during service allowing ongoing water ingress.

- Global examples: The Akashi Kaikyō Bridge in Japan, exposed to marine salt spray, experiences corrosion rates 30% higher than inland bridges. The George Washington Bridge in the U.S., in service for over 80 years, shows internal wire fracture rates of 5–8% due to outdated early corrosion protection, requiring routine dehumidification and wire repairs.

2. Hanger Fatigue Fracture as the “Weak Link” of Structural Safety

Connecting the main cable to the stiffening girder, hangers bear concentrated loads and are subject to both cyclic traffic vibrations and environmental degradation. Fracture risk persists throughout the lifecycle. Failure of a single hanger redistributes stresses among remaining hangers, potentially triggering chain reactions. In 2019, a European river-crossing suspension bridge suffered a partial deck collapse after hanger fracture from corrosion, underscoring the global importance of hanger maintenance.

3. Common Concrete Deterioration of Anchorages and Towers

As reinforced concrete structures, anchorages (fixing the main cables) and towers commonly face honeycombing, surface scaling, cover spalling, and reinforcement corrosion. Severe cases may lead to settlement or deformation. For example, a suspension bridge in India experienced 12 mm uneven settlement of its anchorage foundation during monsoon flooding, forcing traffic restrictions. In Northern Europe, freeze–thaw cycles increase tower cracking rates by 40% compared with temperate regions.

4. Structural-Type-Specific Defects of Stiffening Girders

| Girder Type | Common Defects | Regional Characteristics |

| Steel Truss | Coating failure, joint corrosion | Common in early European bridges (e.g., Forth Road Bridge, UK); complex joints make maintenance challenging |

| Steel Box | Fatigue cracking, wind-induced vibration | Widely used in Asian sea-crossing bridges (e.g., Hong Kong–Zhuhai–Macao Bridge); vulnerable to marine corrosion and typhoon loads |

| Concrete Box | Carbonation, cracking | Favored in inland low-humidity areas (e.g., Germany); lower maintenance cost compared to steel |

Regional Factors Driving Suspension Bridge Defects

- Marine climates (Southeast Asia, Northern Europe, U.S. West Coast): high salt and humidity accelerate cable and hanger corrosion; anchorage carbonation rates more than double.

- Arid desert regions (Middle East, Sahara): sand abrasion damages cable coatings, while large diurnal temperature swings (>25°C) cause thermal cracking in towers.

- Heavy freight corridors (Europe, China): truck loads exceeding design expectations shorten hanger fatigue life and loosen girder connections, reducing durability by 30–50%.

Building a Global Suspension Bridge Inspection and Maintenance System

To address both commonalities and regional variations, a standardized inspection framework combined with localized adaptation is essential for lifecycle risk management.

Global Framework for Inspection

- Initial inspections: record baseline conditions (e.g., coating integrity, anchorage settlement) per ISO and local standards.

- Routine inspections: monthly in marine climates, quarterly in arid inland regions, focused on visible defects.

- Periodic inspections: every 2–3 years with combined manual and equipment-based methods, following AASHTO and regional codes.

- Special inspections: triggered by earthquakes, floods, or ship collisions, using UAVs, load testing, and safety evaluations.

Levels of Inspection Depth

Five standardized levels, from remote visual checks (Level I) to advanced equipment-based diagnostics (Level V), including drones, fiber-optic sensors, cable-climbing robots, and load testing.

Regional Adaptation in Practices

- Manual checks: climate-specific protective tools and equipment.

- Surveying: GPS and leveling with unified data standards (e.g., WGS84).

- Health monitoring systems: regionally adapted sensors (salt-resistant, dust-proof, or seismic).

Key Maintenance Points for Critical Components

- Anchorages: check water ingress, salt monitoring in marine climates, frost-proofing in cold regions, settlement tracking with GNSS.

- Main Cables: monitor coatings, shape, and internal humidity; dehumidification in Europe, wrapping + coatings in China, biannual external protection renewal in Southeast Asia.

- Hangers: regular torque checks of clamps, anti-corrosion layer inspections, robotic wire fracture detection, and preventive replacement cycles (20 years in coastal regions vs. 25 inland).

Global Trends in Suspension Bridge Maintenance

- Integration of Technical Systems: combining regular inspections, preventive maintenance, and intelligent monitoring. Joint EU–China material research has yielded new anticorrosion coatings extending cable life by 50%. U.S.–Japan collaboration developed fatigue models predicting hanger fracture risks.

- Smart Technologies: BIM and digital twin systems support lifecycle management and climate-response simulations. China’s suspension bridge digital twin system has been exported to Malaysia. UAV inspections are standardized under ISO/TS 19159-8 for cross-border comparability.

- Standardization and Knowledge Sharing: ISO, AASHTO, and CEN are harmonizing defect classification and evaluation. Global databases share defect cases and repair solutions to lower technical barriers.

Conclusion

As critical nodes in global transportation, suspension bridges require inspection and maintenance strategies that balance structural commonality with regional specificity. With initiatives such as the Belt and Road and Europe’s Connecting Europe Facility, the future of global suspension bridge maintenance will move toward technical cooperation, unified standards, and shared resources. Through adaptive inspection frameworks and intelligent technologies, lifecycle safety can be ensured, providing more reliable infrastructure for global connectivity.