Reinforced concrete rigid frame arch bridges are widely used in urban and highway construction due to their aesthetic appearance and structural efficiency.

However, under long-term overloading, temperature variation, and foundation settlement, these bridges often exhibit cracking at the arch ribs, beam joints, and deck slab, which affects structural integrity and durability.

While some owners are reluctant to build new rigid frame arches due to historical performance issues, proper diagnosis and reinforcement demonstrate that these structures can still provide excellent service when well maintained.

Today, UAV-based bridge inspection offers engineers a faster and safer way to assess such defects with precision.

1. Common Structural Defects

(1) Bridge Deck Slab Cracking

Most rigid frame arches use lightly reinforced ribbed or shallow-curved slabs. These lightweight deck systems are efficient but prone to cracking when subjected to sustained overloads. Typical issues include:

- Irregular cracks at the slab bottom of ribbed panels, sometimes exposing rebar and causing water leakage;

- Vertical cracks in the stiffening ribs of shallow-curved slabs, which may extend upward to the top surface, leading to longitudinal cracks on the deck.

Inspection Focus: UAV visual imaging and AI crack mapping can efficiently identify bottom-surface cracks and moisture seepage areas.

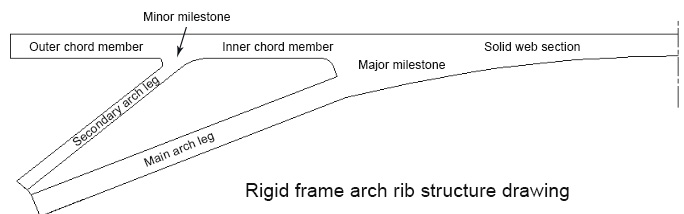

(2) Outer and Inner Chord Members, and Solid Web Segments

Cracks often appear on the outer chord, especially near major and minor joints. Outer chord members act as flexural components, while the inner chord and solid webs are mainly under eccentric compression. Common issues include:

- Vertical cracks at midspan;

- Diagonal cracks around joints;

- Transverse cracks across the tension zone of the web.

Critical defects show wide diagonal cracks penetrating the full depth of the section.

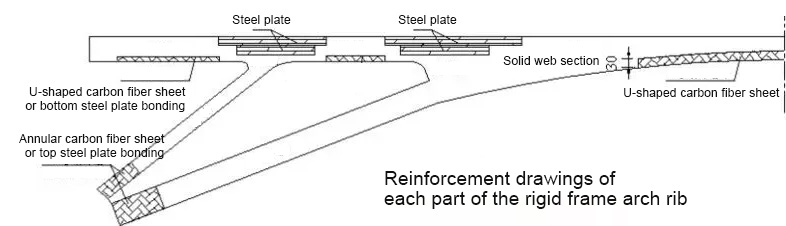

Strengthening options:

- Bonded U-shaped CFRP laminates or steel plates on the tension side;

- Section enlargement with added reinforcement and concrete overlay;

- For eccentric compression members (inner chords), similar reinforcement techniques apply;

- Diagonal crack zones near joints can be reinforced by bonded CFRP strips to resist shear and principal tensile stresses.

(3) Transverse Connections and Crossbeams

Transverse diaphragms typically appear every 3 meters, ensuring lateral stability. However, in damaged bridges, vertical cracks through diaphragms—especially hollow types—are common, indicating compromised integrity.

Strengthening methods:

- When traffic can be closed, strengthen diaphragms by thickening with cast-in-place concrete and rebar anchoring;

- If traffic must remain open, use steel reinforcement frames: attach steel angles to diaphragm corners, clamp them with steel trusses, and weld them into place quickly.

(4) Main Arch Legs and Inclined Struts

Main arch legs and struts are slightly eccentric compression members. Under uneven pier settlement or temperature change, negative bending moments may arise at the strut base, leading to ring-shaped cracks or partial tensile failure.

Reinforcement options:

- Wrap the strut base with fiber sheets or apply steel/CFRP plates on the top surface;

- Alternatively, increase the cross-section for enhanced stability.

(5) Bridge Deck Pavement Layer

The cast-in-place deck layer is an essential part of the structural system, carrying tensile stress in negative-moment regions (near major joints). When these areas are overloaded, transverse deck cracks or longitudinal cracks above arch joints may occur — both are structural cracks requiring reinforcement.

Rehabilitation measures:

- Remove and recast the pavement layer using higher-strength concrete;

- Reinforce with a raised and properly supported rebar mesh;

- Increase deck thickness and improve longitudinal reinforcement in negative moment regions.

2. UAV and AI-Based Inspection Advantages

Traditional inspection of rigid frame arches is difficult and risky due to complex geometry and hard-to-reach underdeck areas.

RIEBO’s UAV bridge inspection solution revolutionizes this process through high-resolution imaging and AI-based defect recognition.

- Aerial Crack Detection: UAVs capture detailed images of soffits, joints, and crossbeams without scaffolding.

- AI Analysis: Automatically identifies crack width, length, and propagation patterns with millimeter precision.

- 3D Modeling & Digital Twin: Converts UAV data into a digital twin for real-time deformation and load analysis.

- Intelligent Maintenance Planning: Integrates inspection results with RIEBO’s bridge management system to recommend targeted reinforcement options like CFRP bonding or external prestressing.

By combining UAV data and AI analytics, RIEBO helps engineers transition from reactive repair to predictive maintenance, enhancing both efficiency and safety.

3. Conclusion

Rigid frame arch bridges, though complex in structure, can achieve long-lasting performance through accurate diagnosis and proper reinforcement. With UAV inspection, AI defect analysis, and intelligent rehabilitation design, RIEBO provides an integrated, data-driven solution for bridge owners worldwide.

Looking to assess or strengthen a concrete arch bridge?

Contact RIEBO today for a customized UAV inspection and digital analysis plan — empowering engineers to detect defects early, optimize repair strategies, and extend bridge service life efficiently.