Masonry arch bridges—constructed with stone, brick, or precast concrete blocks—are among the oldest and most durable bridge types. They can be solid-web or spandrel-open arches and remain widely used in mountainous, rural, and heritage regions due to their aesthetic appearance and long service life.

However, over decades of exposure to weathering, heavy traffic, and differential settlement, these bridges often develop serious issues such as cracking, stone dislocation, mortar loss, and deformation of spandrel walls.

Modern inspection and maintenance technologies, including UAVs (drones) and AI-based visual analytics, now make it possible to diagnose these problems safely, quickly, and accurately—without the need for scaffolding or lane closure.

1. Common Structural Defects

(1) Weathering, Scaling, and Mortar Void

Extensive surface weathering, stone spalling, and voids in mortar joints are common issues. They are usually caused by:

- Poor stone or mortar quality;

- Chemical corrosion from water and air pollutants;

- Long-term freeze-thaw cycles.

If left untreated, these defects can lead to loss of section strength and water penetration into the arch barrel.

(2) Transverse Cracks at the Arch Crown

One or two transverse cracks along the intrados (bottom surface) of the main arch ring are often observed. Different deformation patterns reveal specific causes:

- Noticeable level difference on both sides of the crack → uneven pier settlement;

- No level difference but slight sagging at the crown → piers sliding or rotating outward;

- Crown uplift with crushing cracks → piers moving inward or rotating toward the arch span.

UAV photogrammetry combined with RIEBO’s AI deformation recognition can accurately measure vertical displacement and classify the underlying cause.

(3) Cracked or Crushed Voussoirs

Individual stones in the arch ring may crack, bulge, or crush, often due to concentrated loads, insufficient material strength, or reinforcement corrosion within repaired sections.

(4) Circumferential Cracks Along Construction Joints

When the arch was built in layers, circumferential cracks along the joint plane may form due to construction sequence issues, scaffold deformation, or low mortar strength.

(5) Random Cracks Along Mortar Joints

These surface cracks usually result from poor mortar compaction or low-grade mortar, allowing moisture ingress and accelerating deterioration.

(6) Outward Tilting of Spandrel Walls

Outward tilting or diagonal zigzag cracking along vertical joints—especially in solid-spandrel arches—is a serious issue. It is mainly caused by high lateral earth pressure from backfill under traffic loads.

(7) Separation Between Spandrel Wall and Arch Barrel

Cracks or detachment along the extrados (upper surface of the arch ring) indicate differential deformation between the main arch and the upper spandrel structure. Common causes include pier settlement, temperature stress, or poor mortar bonding.

2. Strengthening and Rehabilitation Methods

(1) Surface Repair and Repointing

For weathered or delaminated surfaces and void mortar joints:

- Remove all loose materials to expose sound substrate;

- Refill joints with high-grade cement mortar or epoxy grout;

- Apply surface mortar coating or shotcrete with fiber additives to improve crack resistance.

(2) Crown Cracks and Settlement-Induced Damage

If cracks result from ongoing pier settlement, the foundation must be stabilized first.

Subsequent arch strengthening may include:

Subsequent arch strengthening may include:

- Epoxy or cement grout injection to seal cracks;

- Steel reinforcement and shotcrete lining along the intrados to increase the arch section;

- Section enlargement from the extrados if the crown capacity is insufficient;

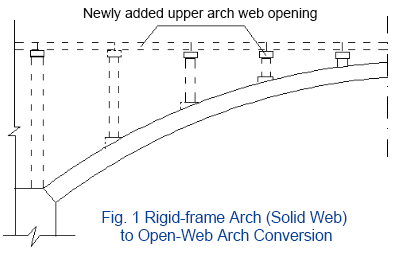

- Load reduction by replacing heavy backfill with lightweight materials or converting a solid spandrel to an open-spandrel form.

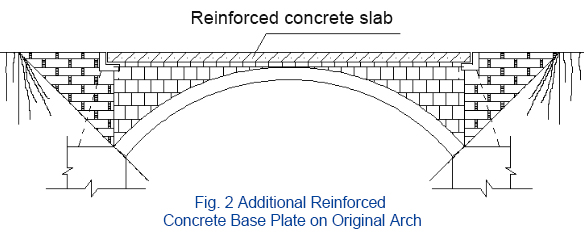

For small-span arches, a reinforced concrete overlay slab can be added atop the crown to create a composite arch-beam system, improving live load capacity.

(3) Individual Voussoir Repair

For cracked or crushed stones:

- Remove the damaged part and repair using epoxy resin or high-strength mortar;

- Severely broken stones should be replaced entirely with new concrete infill or stone blocks.

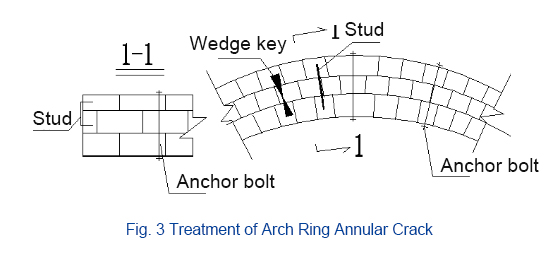

(4) Circumferential Joint Cracks

For cracks along construction joints:

- Embed wedge-shaped steel shear keys or anchor bolts across the joint;

- Seal cracks with cement grout;

- For severe delamination, drill radial anchor rods through the arch ring and prestress them for re-consolidation.

(5) Mortar Joint Cracks

Repoint and grout mortar joints using cement or polymer-modified mortar to restore integrity and prevent water ingress.

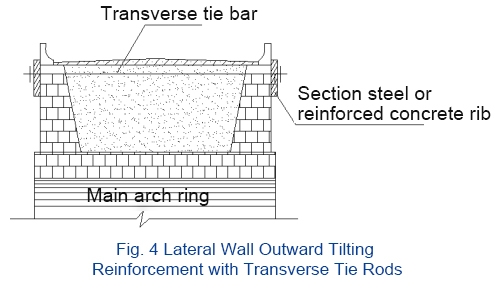

(6) Spandrel Wall Tilting

Depending on the degree of displacement:

- Replace inner backfill with gravel or low-pressure materials;

- For open-spandrel arches, use lean concrete or stone masonry with improved drainage;

- Install transverse tie rods connecting both spandrel walls to restrain outward movement.

(7) Spandrel Wall Separation

If caused by foundation settlement, stabilize the foundation before sealing cracks with high-strength grout. Check expansion joints above the pier for damage to ensure consistent deformation between the superstructure and the main arch.

3. RIEBO’s UAV + AI Bridge Inspection Solution

Conventional inspection of masonry arch bridges—especially over rivers or valleys—is time-consuming and dangerous. RIEBO’s UAV bridge inspection system transforms this process through non-contact imaging and AI-driven analysis.

RIEBO Advantages:

- Aerial Crack Detection: UAVs capture detailed images of arch soffits, spandrel walls, and joints without scaffolding.

- AI-Powered Damage Recognition: Automatically identifies cracks, mortar loss, deformation, and efflorescence patterns.

- 3D Modeling and Digital Twin Integration: Converts UAV data into accurate 3D models for deformation tracking and maintenance planning.

- Intelligent Maintenance Decision-Making: Links inspection results with digital management platforms to recommend targeted reinforcement or repointing strategies.

Through this integration of UAV inspection + AI analytics + digital twin modeling, RIEBO provides a reliable, data-driven approach for diagnosing and maintaining masonry arch bridges.

4. Conclusion

Though masonry arch bridges are historic and robust, they are not immune to deterioration.

By combining traditional repair methods with modern UAV-based inspection and AI evaluation, engineers can ensure structural safety, prolong service life, and preserve cultural heritage.

RIEBO enables bridge owners and engineers to transition from reactive repairs to predictive maintenance—making bridge management smarter, safer, and more cost-efficient.

Need a precise inspection for your masonry arch bridge? Contact RIEBO today for a customized UAV and AI inspection plan — enabling accurate defect detection, efficient rehabilitation, and intelligent bridge lifecycle management.