Concrete truss arch bridges and composite truss arch bridges are widely used for medium- to large-span crossings due to their efficient force transfer and prefabricated construction.

Reinforced concrete truss arches are generally used for shorter spans, while prestressed concrete truss arches are preferred for longer spans.

These structures combine compression arch behavior with truss action, consisting of upper and lower chords, diagonal and vertical members, and solid midspan segments.

The upper chord and solid section resist both axial force and bending, the lower chord works under eccentric compression, and the diagonals and verticals form a tied load path.

Because of complex internal stresses, prestressing is often applied to the upper chord, diagonal members, and solid segments to improve stiffness and crack resistance.

However, long-term overloading, material aging, and construction defects often lead to cracking and deformation. Below are the common defects and strengthening methods, along with how RIEBO’s UAV inspection and AI analysis help detect and manage these issues efficiently.

1. Common Structural Defects

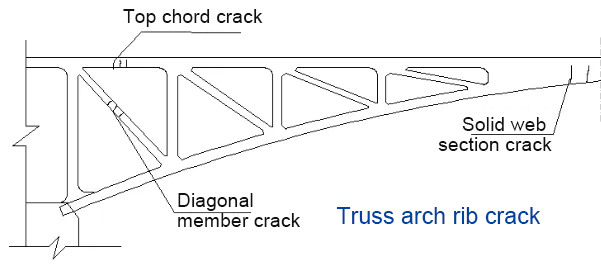

(1) Cracks in the Upper Chord and Solid Web Segments

Transverse cracks at the bottom and sides of the upper chord or solid midspan section are common, sometimes accompanied by excessive midspan deflection.

These defects typically indicate insufficient prestressing, undersized section depth, or inadequate reinforcement.

RIEBO UAV inspection enables high-resolution imaging under the bridge, detecting such cracks and deflection trends accurately without scaffolding.

(2) Cracking in Diagonal Members

Diagonal tension members may develop longitudinal cracks, indicating excessive tension or loss of prestress.

In severe cases, cracking can spread toward the joint, reducing stiffness and altering load paths.

AI-assisted image analysis from RIEBO automatically classifies crack severity and helps engineers determine whether the issue is prestress loss or tension overload.

(3) Cracks or Crushing in Lower Chord and Vertical Members

The lower chord and vertical members are eccentric compression components.

When section size is insufficient, multiple cracks or local crushing can occur along the member length.

If cracks run perpendicular to the member axis, it suggests high slenderness or excessive truss deformation causing secondary bending.

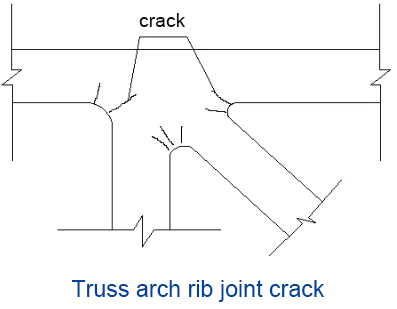

(4) Cracking Around Joints

Joints are common stress concentration zones because member axes rarely intersect perfectly.

Under repeated loads, temperature stress, or fatigue, local cracking occurs around these nodes, especially near welded or concrete joints.

UAV inspection can capture high-resolution joint imagery, enabling detailed defect mapping and change tracking over time.

(5) Transverse Connection Cracks

Transverse members (such as diaphragms, cross girders, or bracing) may exhibit vertical or inclined cracks, especially when the truss plane lacks transverse rigidity.

These defects are more pronounced when cross-beam dimensions are small or when transverse bracing is weak.

(6) Joint and Assembly Defects

Since truss arch bridges are mostly prefabricated and assembled, joints are weak points:

- Dry joints may loosen or fatigue due to poor welding quality;

- Wet joints may crack when the interface strength is inadequate.

(7) Deck Slab Cracks

Deck slabs in truss arch bridges are typically reinforced or prestressed concrete panels, such as micro-curved slabs or hollow slabs.

In composite truss arches, unidirectional or bidirectional slabs are common. Their deterioration—cracking, delamination, or leakage—is similar to that in rigid frame arch bridges.

2. Strengthening and Rehabilitation Methods

(1) Upper Chord, Diagonal Members, and Solid Segments

- For mild cracks, apply bonded CFRP sheets or steel plates.

- For severe damage, use external prestressing or section enlargement with reinforced concrete encasement.

- A combined method—tensioning external tendons and then wrapping with reinforced concrete—provides the best long-term stiffness recovery.

(2) Lower Chord and Vertical Members

- Prefer section enlargement to increase compressive capacity.

- For moderate cracks, apply steel banding or CFRP wrapping for confinement and crack control.

(3) Joint Cracks

- Reinforce with bonded steel plates or block-type CFRP laminates to improve local shear and tensile strength.

- For severely damaged welded joints, use re-welding or anchor bar reinforcement.

(4) Transverse Connection Cracks

- Strengthen by increasing crossbeam size, adding new transverse members, or applying transverse prestress.

- For minor cracking, local reinforcement with CFRP or steel plates is sufficient.

(5) Assembly Joint Defects

- Strengthen using grouting, welding repair, anchor bar installation, or steel plate bonding.

- For wet joints, re-grouting with epoxy or cement slurry restores shear continuity.

3. RIEBO’s UAV + AI Bridge Inspection and Analysis Solution

Traditional bridge inspection methods rely heavily on manual visual checks, which are inefficient and limited in coverage. RIEBO provides an intelligent, data-driven alternative using UAVs and AI-powered analytics.

Key Capabilities:

- High-Resolution UAV Imaging: Captures full truss geometry, including joints, diagonal rods, and deck undersides.

- AI Crack Detection: Automatically identifies crack length, width, and pattern, distinguishing between structural and surface defects.

- 3D Digital Twin Modeling: Converts UAV data into a full digital model for stress visualization and defect tracking.

- Predictive Maintenance: Integrates inspection data with RIEBO’s digital bridge management platform, supporting targeted reinforcement plans like CFRP bonding or external prestressing.

By combining UAV inspection, AI analysis, and digital twin modeling, RIEBO enables accurate, non-contact, and cost-effective condition assessment for complex concrete truss arch bridges.

4. Conclusion

Concrete truss arch and composite truss arch bridges combine elegance and strength but are highly sensitive to stress concentration, prestress loss, and joint deterioration.

Through advanced inspection technologies and modern strengthening methods such as CFRP reinforcement, external prestressing, and digital analysis, these structures can be effectively rehabilitated and maintained.

RIEBO’s UAV + AI bridge inspection solution provides engineers with the data accuracy and insight needed for smarter, faster, and safer decision-making—extending the service life of critical bridge assets.

Looking to inspect or strengthen your concrete truss arch bridge? Contact RIEBO today for a customized UAV inspection and AI analysis plan — enabling intelligent diagnosis, precise reinforcement, and sustainable bridge management.