Half-through and deck arch bridges are ribbed arch structures whose arch ribs are typically constructed from reinforced concrete in rectangular, I-shaped, or box-shaped sections—the latter being more common. Steel tubes, concrete-filled steel tubes, or hybrid combinations are also widely used.

Structurally, these bridges can be categorized into thrust arches and tied arches (i.e., arches without horizontal thrust). Compared with through arch bridges, their distinguishing components include hangers, hanger crossbeams (sometimes accompanied by longitudinal beams), and tie rods. Hangers may be rigid or flexible, with flexible types being more frequently applied.

Tie rods may also be either rigid or flexible. Medium-through (seagull-type) tied arch bridges often utilize flexible high-strength steel wire as tie rods. Deck-type tied arches can be grouped into flexible-tie rigid-arch systems, rigid-tie rigid-arch systems, and rigid-tie flexible-arch systems, with the first two being more common.

In addition to defects that are also found in through arch bridges, half-through and deck arch bridges may experience the following issues:

(1) Hanger Anchorage Defects

Hanger anchor heads may loosen or corrode; hanger wires may also corrode or fracture. Anchor heads located beneath the deck and at short hanger ends are especially prone to such deterioration.

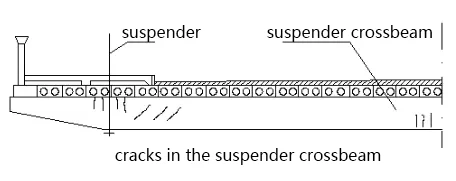

(2) Hanger Crossbeam Cracking

The hanger crossbeam—typically a simply supported beam or double-cantilever simply supported beam made of reinforced or prestressed concrete—may develop:

- Vertical flexural cracks at the midspan underside

- Diagonal web cracks near the hanger attachment points

- Longitudinal cracks on the top surface at hanger positions

In beam-grid deck systems containing both crossbeams and longitudinal beams, cracking may also occur near:

- The joints between longitudinal and transverse beams

- The joints between the arch rib and rigid tie rod

(3) Tie Rod Deterioration

Tie rod anchor heads may loosen or corrode, and steel wires may corrode or fracture.

Rigid tie rods, which bear axial force and local bending (similar to continuous beams on elastic supports), are prone to common flexural component defects.

Common Strengthening Methods

(1) Repairing Hanger or Tie Rod Anchorage Issues

Where conditions allow, loosened anchor heads or slipped wires should be retensioned to restore internal forces or elevation:

- Flexible hangers with saddle-type anchorages can be retensioned by adding steel shims.

- Tie rods with wedge anchorages should undergo supplementary tensioning and re-anchoring.

Where corrosion or wire fracture is severe, or where retensioning is not feasible, cables should be replaced through pre-reserved ducts; if ducts were not pre-installed, temporary unloading measures must be implemented prior to replacement.

(2) Strengthening Cracked Crossbeams, Longitudinal Beams, and Rigid Tie Rods

Cracking in hanger crossbeams, longitudinal beams, or rigid tie rods may be strengthened using methods similar to those for reinforced or prestressed concrete beams, including:

- External prestressing

- Bonded steel plate reinforcement

- Fiber-reinforced polymer (FRP) strengthening

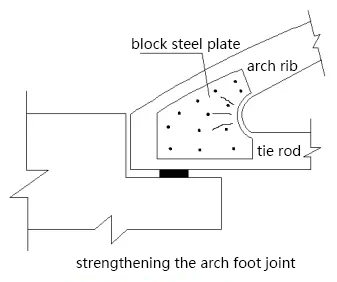

(3) Strengthening Cracked Beam Joints and Arch Foot Joints

Simple reinforcement may be achieved by bonding block-type steel plates or fiber composite materials at the cracking locations.

RIEBO UAV Bridge Inspection Solution

RIEBO Tech provides a full suite of intelligent inspection and structural strengthening advices tailored for different bridges:

- Drone + AI Visual Inspection – High-resolution UAVs automatically identify cracks, spalling, and corrosion on the beam soffit, webs, and anchorage zones.

- Digital Twin Modeling – Converts inspection data into a 3D structural model for visualization, analysis, and defect progression prediction.

- Customized Strengthening Design – Provides detailed reinforcement plans such as CFRP strengthening, external prestressing, or beam replacement based on inspection data.

- Lifecycle Health Management – From inspection to post-reinforcement monitoring, RIEBO builds a comprehensive digital health record for each bridge, optimizing long-term maintenance and safety.

Looking to assess or strengthen your bridge structures?

Contact RIEBO today for a professional UAV inspection and customized reinforcement plan — empowering safer, longer-lasting bridges with intelligent technology.