Among all operating bridge types worldwide, reinforced concrete (RC) and prestressed concrete (PC) simply supported beam bridges account for the largest proportion.

These structures are widely used for their mature design, high reliability, and short construction periods. Typical cross-sections include T-beams, I-beams, box girders, and composite sections.

However, as service life extends and traffic loads increase, various structural defects gradually appear, threatening the bridge’s safety and durability.

This article outlines the most common structural defects, their causes, and practical reinforcement methods, along with RIEBO’s advanced inspection and strengthening solutions for effective bridge health management.

Common Defects in Reinforced Concrete Simply Supported Beam Bridges

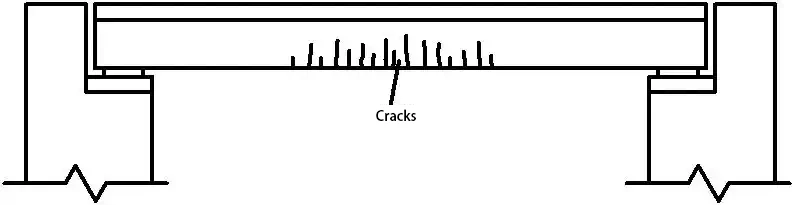

(1) Vertical Flexural Cracks at Midspan

These cracks appear on the bottom of beams near the midspan, caused by excessive bending stress from dead and live loads. Their number and width increase with span length, and in severe cases, excessive midspan deflection may occur.

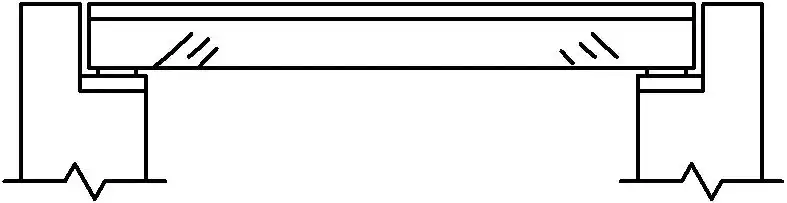

(2) Diagonal Cracks on the Web

Typically found near the supports, these shear-induced diagonal cracks form at about 45° to the beam axis due to insufficient shear capacity or excessive principal tensile stress.

(3) Vertical Shrinkage Cracks on the Web

These fine cracks usually occur in the thin web region, with a wider middle and narrow ends. They result from poor curing, temperature variation, or insufficient horizontal reinforcement, and mainly affect long-term durability by accelerating carbonation and corrosion.

(4) Longitudinal Cracks on the Deck

Often found along the flange joints of precast T-beam bridges, they tend to worsen if transverse connections deteriorate, leading to uneven load distribution and progressive damage.

Common Defects in Prestressed Concrete Simply Supported Beam Bridges

Partially prestressed (Class B) beams may share similar issues with RC beams, though usually to a lesser extent.

However, for fully or partially prestressed Class A members, cracks are not allowed under normal service conditions. Any crack, regardless of width, indicates a structural issue requiring immediate inspection and treatment.

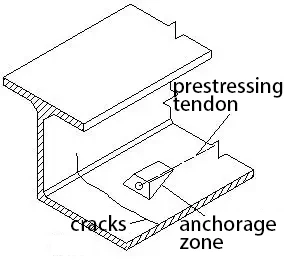

(1) Longitudinal Cracks Behind Anchorage Zone

Caused by local stress concentration at the anchorage zone, these cracks typically extend vertically along the beam height.

(2) Longitudinal Cracks along Prestressing Tendons

These occur due to insufficient cover thickness, localized stress near tendons, or corrosion after concrete carbonation, resulting in splitting along the tendon path.

(3) Excessive Midspan Deflection

While not always accompanied by cracking, this issue is commonly caused by insufficient prestressing force or excessive long-term prestress loss, reducing structural stiffness and serviceability.

Reinforcement and Repair Methods

(1) Steel Plate or Fiber Reinforced Polymer (FRP) Bonding

For flexural or longitudinal cracks, bonding steel plates or CFRP sheets to the beam soffit significantly increases bending capacity and stiffness without adding much dead weight.

(2) Section Enlargement Method

Increasing the thickness of the deck or bottom flange enhances the compression zone and overall stiffness. However, this method must carefully control additional self-weight to avoid secondary stresses.

(3) Shear Crack Strengthening

For diagonal cracks, apply FRP sheets or steel plates at approximately 45° opposite to the crack direction. When anchorage length is limited, U-shaped wrapping or strip confinement can be adopted.

(4) Crack Sealing and Epoxy Injection

Shrinkage and anchorage zone cracks should be sealed or injected with epoxy resin to prevent moisture ingress and corrosion propagation.

(5) Deck and Transverse Reinforcement Improvement

For longitudinal deck cracks, modify the deck overlay, add transverse reinforcement, or install additional diaphragms to redistribute stresses.

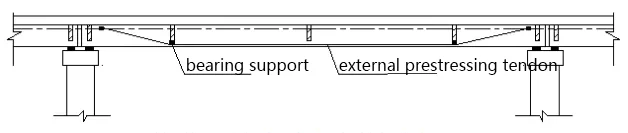

(6) External Prestressing

Installing external tendons or CFRP cables can effectively restore stiffness and bearing capacity. Though technically complex, it’s one of the most efficient methods for severely deteriorated beams.

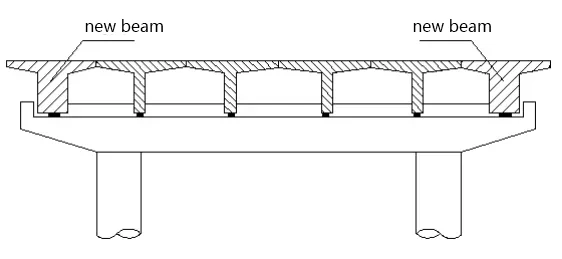

(7) Beam Replacement

If a beam suffers extensive damage or deformation, it can be replaced with a higher-stiffness beam to restore load-bearing capacity and balance load distribution.

RIEBO’s Intelligent Bridge Inspection and Reinforcement Solutions

RIEBO Tech provides a full suite of intelligent inspection and structural strengthening advices tailored for different bridges:

- Drone + AI Visual Inspection – High-resolution UAVs automatically identify cracks, spalling, and corrosion on the beam soffit, webs, and anchorage zones.

- Digital Twin Modeling – Converts inspection data into a 3D structural model for visualization, analysis, and defect progression prediction.

- Customized Strengthening Design – Provides detailed reinforcement plans such as CFRP strengthening, external prestressing, or beam replacement based on inspection data.

- Lifecycle Health Management – From inspection to post-reinforcement monitoring, RIEBO builds a comprehensive digital health record for each bridge, optimizing long-term maintenance and safety.

Conclusion

Reinforced and prestressed concrete simply supported beam bridges, though mature in design, remain vulnerable to fatigue and environmental degradation over time.

Through scientific inspection and targeted strengthening, their service life can be significantly extended and maintenance costs reduced.

With RIEBO’s intelligent UAV inspection, AI analysis, and advanced reinforcement technologies, bridge owners can shift from reactive repairs to proactive maintenance, ensuring long-term structural safety and sustainability.

Looking to assess or strengthen your bridge structures?

Contact RIEBO today for a professional UAV inspection and customized reinforcement plan — empowering safer, longer-lasting bridges with intelligent technology.