Among highway bridges widely used around the world, simply supported girder bridges and concrete box girder bridges have become mainstream types due to their mature structural design and convenient construction process. However, under the combined influence of load effects, environmental erosion, and construction deviations, cracking has become one of the most common structural defects in both types. Understanding the common crack patterns and their causes is of great significance for bridge maintenance and safety assurance.

Common Cracks in Reinforced Concrete Simply Supported Beam (Slab) Bridges

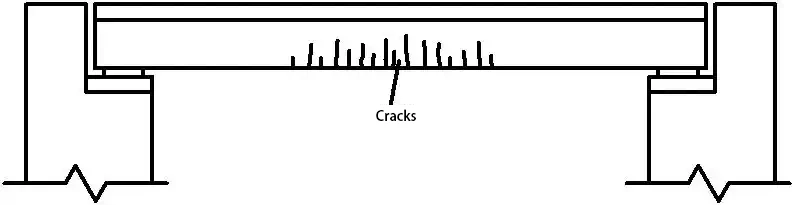

Vertical cracks in the tension zone at the lower edge

Caused by excessive bending stress, these vertical cracks typically appear at mid-span and in tension zones, directly reflecting flexural stress effects.

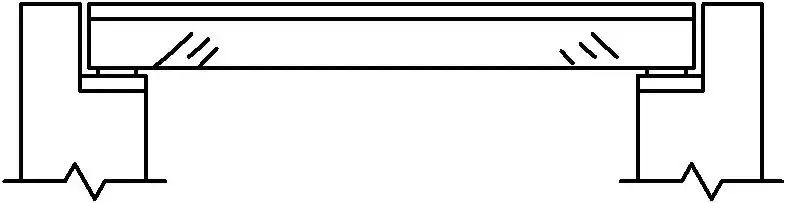

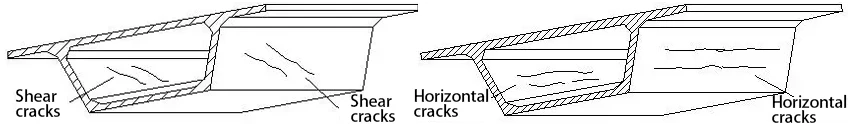

Diagonal cracks on the web

Resulting from excessive principal tensile stress caused by shear, bending, or torsion. These inclined cracks appear on the web and reduce shear resistance.

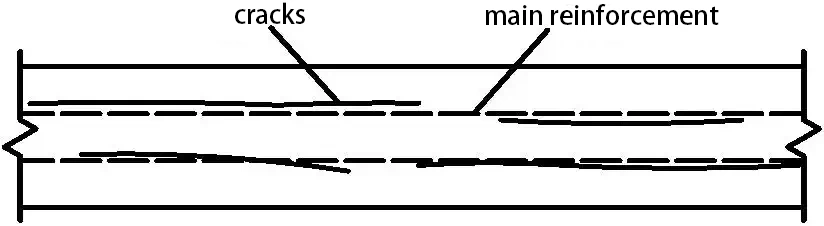

Longitudinal cracks along main reinforcement

Moisture penetration leads to steel corrosion and expansion, cracking the concrete along the rebar, which accelerates corrosion.

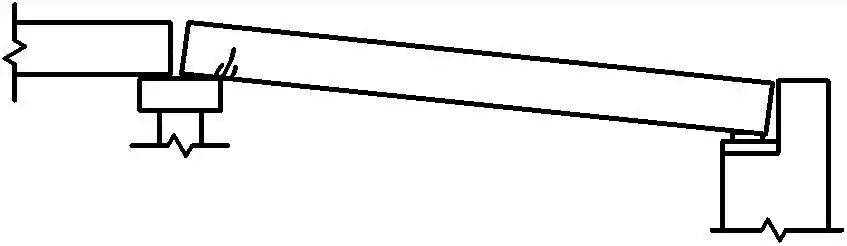

Top cracks at beam ends

Uneven settlement of piers or abutments increases local stress at beam ends, forming cracks near the upper surface and affecting load transfer.

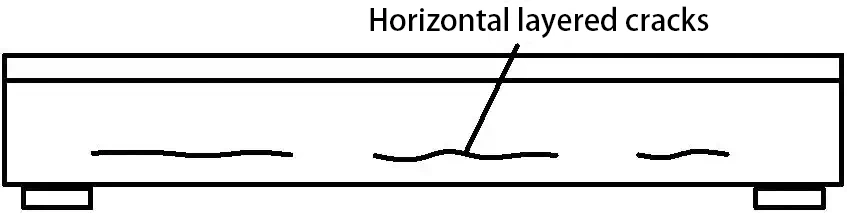

Horizontal layered cracks

Caused by improper pouring with long intervals between layers, leading to poor bonding and weakened integrity.

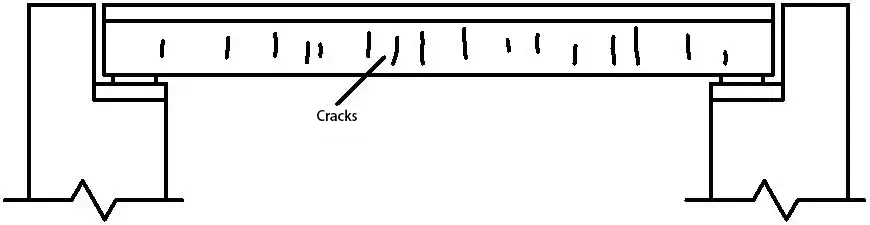

Irregular vertical cracks on webs

A combined result of structural configuration, concrete shrinkage, and external forces, showing irregular distribution.

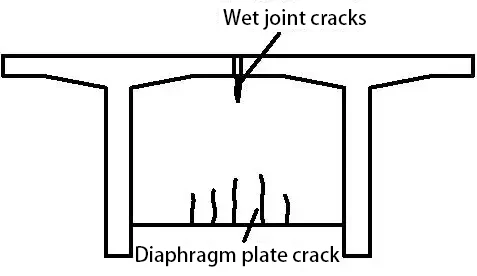

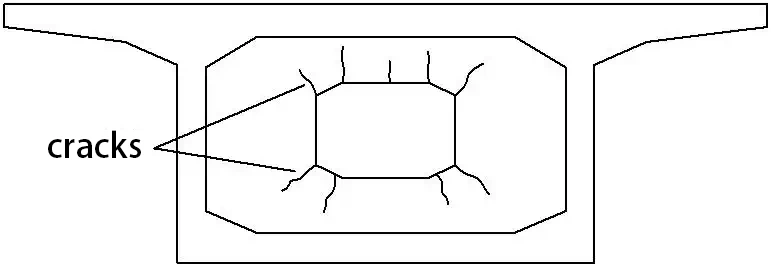

Cracks around diaphragms

Wet joint cracks due to poor construction or design; vertical cracks at diaphragm bottoms arise from insufficient transverse stiffness.

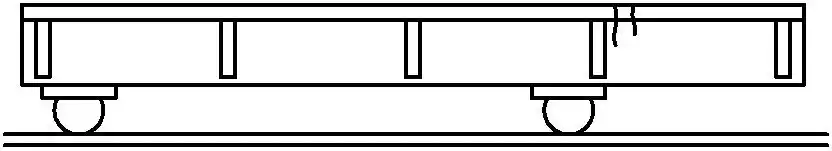

Cracks from improper beam transportation

Abnormal stress during transport may cause random-position cracks, directly compromising integrity.

Common Cracks in Prestressed Concrete Continuous (Box) Girder Bridges

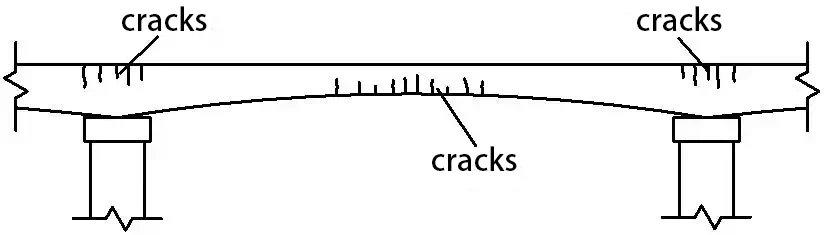

Vertical cracks from bending

Found at mid-span bottoms or near supports, caused by insufficient flexural stiffness or low concrete strength.

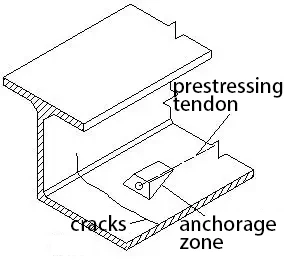

Cracks near anchorage zones

Transverse cracks appear behind anchor plates due to local tensile stress concentration; minor horizontal cracks may form at prestressing ends.

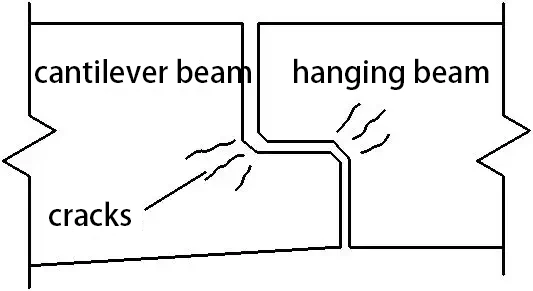

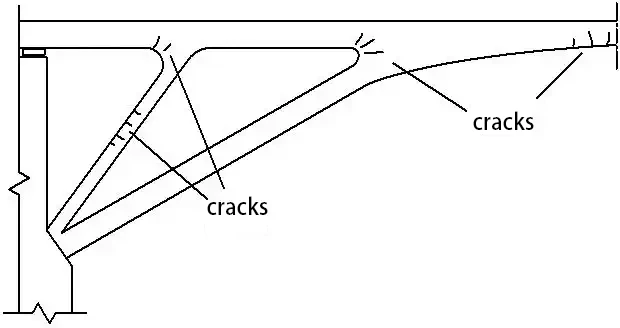

Cracks in corbels or hanging beams

Caused by inadequate reinforcement, low height, or impact from hanging beams, leading to local cracking and instability.

Longitudinal cracks at lower flange

Resulting from excessive prestress, thin cover, or poor workmanship, reducing prestress efficiency.

Shear and horizontal cracks on webs

Inclined cracks due to shear stress and horizontal cracks from transverse bending; both reduce web capacity.

Longitudinal cracks at haunches

Concentrated at junctions of deck/bottom slabs and webs due to local prestress concentration.

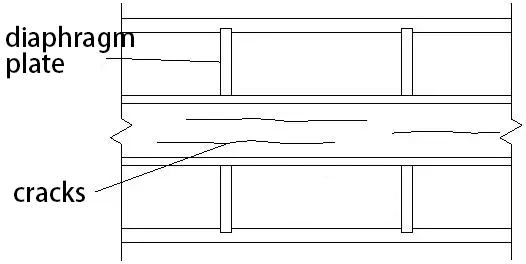

Cracks at diaphragms or segment joints

Caused by insufficient transverse prestress, torsional weakness, or poor joint casting.

Cracks from eccentric loads and torsion

Uneven loads, torsional effects, or poor workmanship can cause irregular cracking, disturbing load balance.

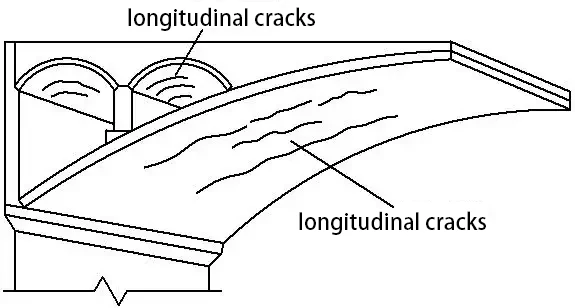

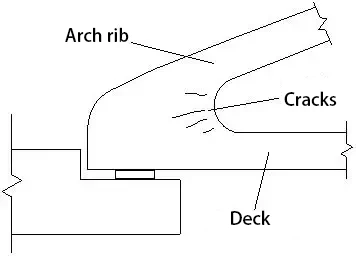

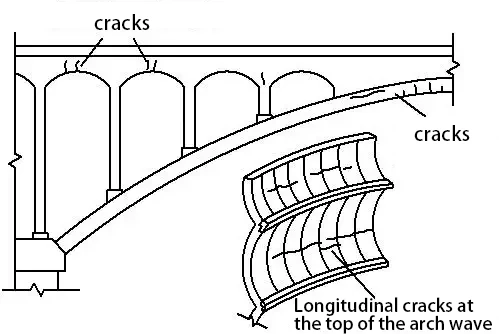

Cracks in Arch Bridges (Including Box Girder-Arch Combinations)

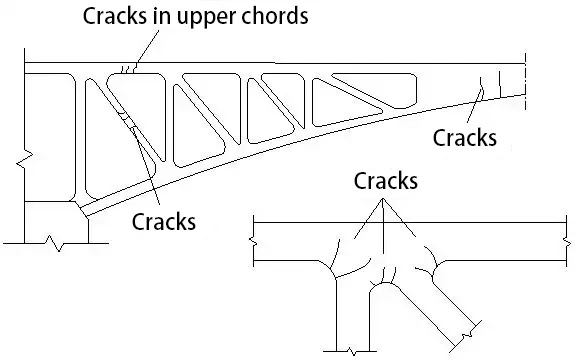

Cracks in arch ribs and rings

Caused by undersized sections, design defects, or overloads, often leading to longitudinal cracks in masonry arch rings.

Cracks in upper chords and solid sections

Transverse cracks near mid-span suggest inadequate prestress; cracks in diagonal rods indicate tensile overstress.

Cracks from pier/abutment settlement

Uneven foundation settlement causes longitudinal cracks in arches, especially under eccentric loads.

Deck and hanger-related cracks

Deck cracking due to insufficient prestress, excessive tensile stress, or poor joint detailing; hanger cracks relate to fatigue or poor force transfer.

Cracks in double-curved arch bridges

Weak transverse connections and uneven pier settlement lead to irregular cracking, affecting stability.

Conclusion

Bridge cracking typically results from a combination of mechanical, material, and environmental factors. Early detection and targeted repair measures can effectively slow deterioration and extend service life. Routine inspections should focus on crack width, length, and propagation rate to provide accurate data for structural safety assessment.

If you are looking for a professional drone bridge inspection solution, RieboTech can provide an integrated service covering everything from flight platform selection and data acquisition to AI defect detection and digital twin management. Contact us today to make your bridge maintenance safer and more efficient.