Simply supported slab bridges are widely used in small- and medium-span urban and highway projects because of their low structural height, ease of construction, safety in transportation and installation, stability, short construction periods, and low cost. To reduce self-weight and save materials, most bridges of this type adopt hollow slab structures.

However, due to structural characteristics and environmental influences, many of these bridges develop various types of damage during service, such as:

- Uneven load distribution between slabs,

- Water leakage through hinge joints,

- Water accumulation inside hollow slabs,

- Longitudinal cracks at the slab bottom, and

- Efflorescence or leakage on side wings.

These issues directly threaten bridge safety and shorten service life.

This article analyzes the main causes of these damages based on extensive inspection and reinforcement experience and proposes corresponding preventive and treatment measures, providing useful guidance for maintenance of hollow slab bridges.

1. Causes of Bridge Deterioration

1.1 Uneven Load Distribution

This is one of the most typical issues in simply supported slab bridges.

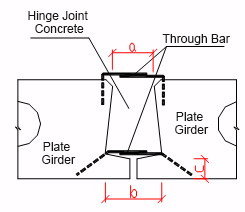

Normally, slabs are connected with hinge joints using interlocking concrete and embedded rebar to form an integrated structure.

Schematic diagram of the slab and beam hinge joint structure

However, when hinge joint concrete quality is poor, load transfer between slabs weakens, and a single slab may bear excessive stress — a condition known as single-slab loading.

Longitudinal grooves have appeared on the bridge deck

The deflection of a single beam under force is obvious

Causes include:

- Poor hinge concrete quality – Inadequate strength, improper bonding between old and new concrete, insufficient vibration leading to honeycombing, and rebar misalignment. These defects make the hinge joint the weak point in the entire structure.

- Template displacement during construction – Inaccurate formwork installation or size deviations cause the hinge connection to misalign, preventing proper load transfer.

- Weak bridge deck pavement – Differences in concrete curing age between the deck and the slabs cause shrinkage cracks, leading to leakage and deterioration.

- Vehicle overloading – Excessive load increases shear stress at hinge joints, eventually causing shear failure.

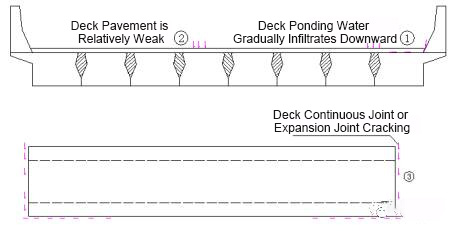

1.2 Hinge Joint Water Leakage

More than 50% of slab bridges experience water leakage at hinge joints. Rainwater seeps through gaps between the hinge concrete and slab walls, gradually dissolving calcium hydroxide and other compounds, leading to concrete corrosion and rebar rusting. Over time, this weakens the hinge joint’s shear resistance, causing single-slab loading failures.

The seepage path of the hinge joint of the slab and beam

Main leakage sources include:

- From curbs (deck edges): Water trapped by cross slopes seeps down to the hinge joint.

- From pavement joints: Cracks in the concrete or insufficient waterproofing allow rainwater to penetrate through the deck into hinge gaps.

- From beam ends: Poor expansion joint waterproofing allows water infiltration that spreads inward along the hinge.

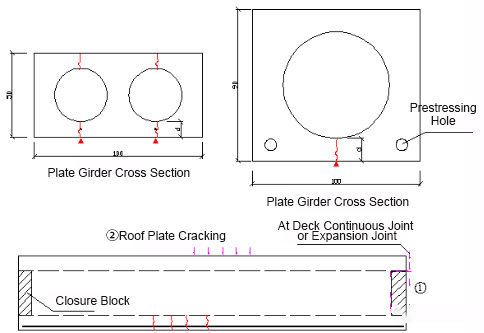

1.3 Internal Water Leakage

Internal leakage occurs when rainwater enters the hollow cavities of slabs and seeps out through cracks at the bottom. This accelerates steel corrosion and concrete degradation, significantly shortening bridge lifespan.

Water seepage pathways within the board

Causes include:

- Cracks at the slab top or end caused by poor vibration, uneven concrete thickness, or improper curing.

- Shrinkage cracks in the mortar blocks used to seal the ends.

- Poor waterproofing at the deck surface allowing water to penetrate.

Once water accumulates inside the slab, it corrodes rebar and causes swelling, leading to bottom cracking and further deterioration.

1.4 Bottom Slab Cracking

Cracks often develop along the longitudinal or transverse direction of hollow slabs. In prestressed concrete structures, such cracks indicate insufficient bearing capacity and can accelerate steel corrosion once water penetrates.

Typical causes include:

- Excessive tensile stress – Premature tensioning, uneven slab thickness, or high prestressing forces.

- Lack of positioning rebar – Thin bottom concrete and poor compaction lead to shrinkage cracks.

- Water ingress inside ducts – Causes rebar corrosion and regular longitudinal cracking.

- Load-induced bending stress – Normal concrete slabs under positive bending moments may exceed tensile strength limits.

2. Preventive and Remedial Measures

2.1 Preventing Single-Slab Loading

To prevent single-slab loading, strict control is required at design, construction, and maintenance stages:

- Design:

Ensure hinge concrete thickness ≥ 12 cm, with additional reinforcement and minimum deck thickness ≥ 10 cm.

Increase hinge concrete strength and rebar density if necessary. - Construction:

Follow dimensional tolerances strictly and ensure full compaction and bonding quality. - Management:

Enforce vehicle load limits to prevent overstressing.

2.2 Preventing Hinge Joint Leakage

Key preventive actions include:

- Applying reliable waterproof layers, especially around curb areas.

- Ensuring deck concrete is placed continuously to avoid longitudinal joints.

- Reinforcing deck steel mesh to minimize cracking.

- Maintaining and sealing expansion joints properly.

2.3 Preventing Internal Water Leakage

- Strengthen early curing of precast slabs to prevent top cracking.

- Increase deck concrete thickness and improve waterproofing to block water ingress.

- For slabs with internal water accumulation, install drainage holes to discharge trapped moisture.

2.4 Repairing Bottom Cracks

- Assess the severity of cracking.

- For minor, non-leaking cracks — apply sealing treatments.

- For cracks with water leakage — fix waterproofing first, drain internal water, then reseal the crack thoroughly.

3. Conclusion

The analysis leads to the following conclusions:

- Strictly follow design requirements to ensure construction quality.

- Strengthen curing of precast slabs to prevent shrinkage cracking.

- Improve post-construction maintenance and repair work for early detection and mitigation of damage.

- Strictly control overloading and enhance traffic management.

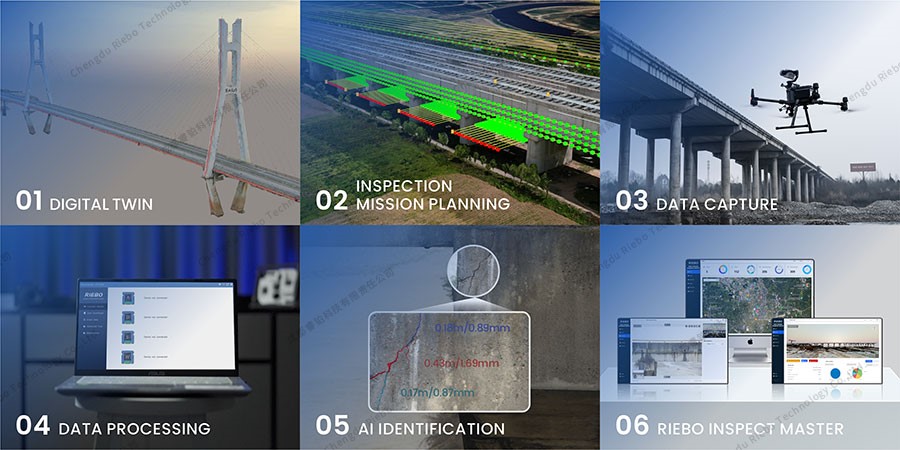

Integrating Drone Inspection for Smarter Bridge Maintenance

In addition to traditional inspection methods, Riebo’s Drone Bridge Inspection Solution offers an innovative way to monitor and assess simply supported slab bridges. Equipped with high-resolution cameras, AI-based defect recognition, and 3D modeling capabilities, Riebo’s solution can quickly identify cracks, water leakage zones, and structural deterioration from multiple angles.

By combining these aerial inspection results with engineering analysis, bridge management teams can perform faster, safer, and more precise evaluations, enabling proactive maintenance and extending the bridge’s service life.