Simply supported slab bridges are widely used in small- and medium-span bridge projects due to their simple structure, convenient construction, and cost efficiency. They are commonly found in urban branch roads, rural highways, and industrial park roads. However, as service years increase, vehicle loads intensify (especially with the rise of heavy traffic), and natural deterioration (rain erosion, freeze-thaw cycles, carbonation, etc.) progresses — combined with construction and design deficiencies — many slab bridges show signs of structural degradation and frequent defects, posing safety and durability risks.

Compared with rebuilding, bridge reinforcement offers significant advantages: it reduces initial investment (avoiding demolition and reconstruction costs), shortens construction time, and minimizes traffic disruptions — delivering both economic and social benefits. However, research on specialized design and precise calculation for slab bridge reinforcement remains limited. The lack of standardized analytical methods for defect causes and reinforcement effect prediction increases design difficulty. Therefore, reinforcement designers must not only master structural mechanics and material science but also possess rich engineering experience to propose practical, economical, and reliable solutions that ensure both efficiency and long-term performance.

If a reinforcement plan is based only on construction experience without sufficient structural analysis, it may misidentify key problem areas — strengthening unnecessary zones while neglecting critical ones — resulting in wasted materials and unsatisfactory performance. Furthermore, some designers rely on empirical material estimations without precise calculations, making it difficult to assess material sufficiency or post-reinforcement performance compliance. In reality, most slab bridge defects appear during normal service, and simply calculating load-bearing capacity before and after reinforcement is not enough. Structural safety requires a deeper understanding of internal stress distribution and defect progression through detailed stress analysis — providing the scientific foundation for targeted reinforcement design.

I. Common Defects in Simply Supported Slab Bridges

Defects mainly relate to structural stress behavior, material aging, construction deficiencies, and environmental conditions, commonly manifesting as deck cracks, bearing failures, joint deterioration, and mid-span deflection:

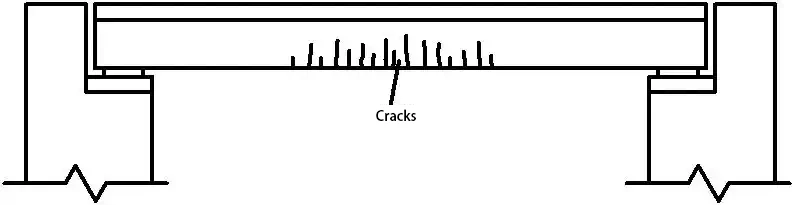

Slab Cracks (Most Typical Issue)

- Vertical cracks near mid-span: Usually multiple vertical cracks at the slab’s tension zone, exceeding standard width limits (≤0.3 mm), often accompanied by mid-span sagging — indicating insufficient bending capacity.

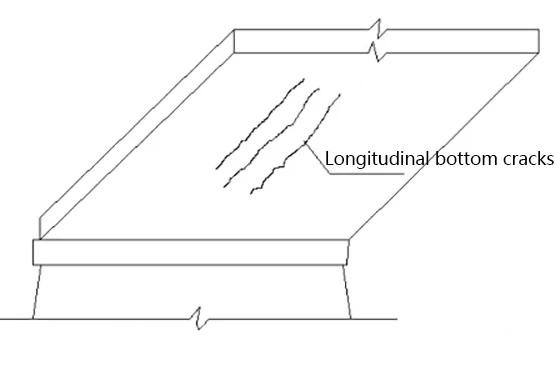

- Longitudinal bottom cracks: May result from improper reinforcement layout, concrete carbonation, chloride-induced corrosion, or inadequate bottom slab thickness — typically following reinforcement direction.

- Inclined web cracks: Common in large hollow slabs (>1.5 m width), caused by high shear stress near supports, reducing shear resistance.

Hinge Joint Deterioration

Prefabricated slabs often develop longitudinal cracks along hinge joints due to poor concrete compaction or insufficient reinforcement continuity, weakening slab integrity and causing uneven load transfer.

Bearing System Issues

Due to numerous supports per span, slab bridges often experience bearing voids from elevation errors, installation warping, or pier settlement — leading to uneven load distribution and accelerated damage.

Mid-Span Deflection

Long-term load exposure, creep, and corrosion can cause excessive sagging, reducing stiffness and accelerating cracking.

II. Practical Strengthening Methods for Simply Supported Slab Bridges

The strengthening of simply supported slab bridges should be based on the type and severity of damage, structural condition, and service requirements. The chosen reinforcement method should be targeted, economical, and efficient. Below are several mature and commonly used strengthening techniques:

Bonding Reinforcement Method (for slab cracks and insufficient flexural capacity)

The steel plate bonding and fiber-reinforced polymer (FRP) bonding methods (using carbon fiber or glass fiber fabrics) are suitable for cases where longitudinal or transverse cracks exceed allowable widths and flexural strength is insufficient, but the overall structural stiffness remains acceptable.

The process involves sealing and grouting the cracks at the slab bottom, then bonding steel plates or FRP sheets to the tension zone using special adhesives. These materials share the tensile stress of the reinforcing bars, enhancing the slab’s flexural and crack resistance.

This method offers simple construction, short duration, minimal traffic disruption, and no alteration to the original structural form. FRP materials, in particular, are lightweight, corrosion-resistant, and durable, ideal for humid environments or weight-sensitive structures.

However, before bonding, the concrete surface must be smooth, dry, and clean, and the adhesive should meet strength and durability requirements. Post-bonding curing is also essential to ensure adhesion quality.

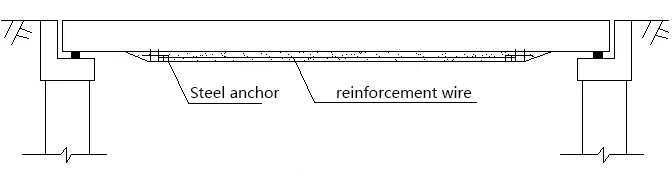

Prestressing Reinforcement Method (for mid-span deflection and flexural deficiencies)

This technique is suitable for bridges with significant mid-span deflection or serious flexural capacity deficiencies. By applying prestress, it enhances stiffness, improves load-bearing capacity, and suppresses crack development.

Two common approaches are:

- Linear prestressing at the slab bottom, where multiple parallel prestressing wires are anchored and tensioned, followed by protective concrete casting. This counteracts part of the mid-span bending moment, reducing deflection and crack width.

- External deviated prestressing, where prestressing tendons are arranged in a polygonal layout using deviator brackets and anchored under the deck pavement. This not only improves flexural performance but also optimizes load distribution.

The method is highly effective in reducing mid-span deflection and improving durability without significantly increasing self-weight. However, tension control is crucial — overstressing may damage the slab, and anchorage reliability must be ensured to prevent prestress loss.

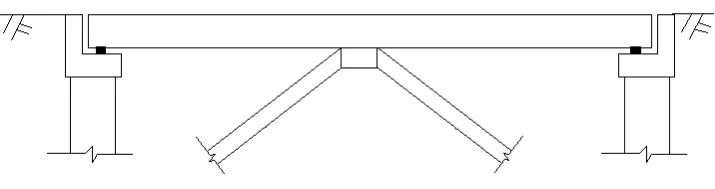

Structural System Modification Method (for long spans and insufficient stiffness)

This method enhances overall load-bearing capacity by altering the structural system to reduce mid-span bending moments. The two common approaches are “simply supported to continuous conversion” and “adding mid-span supports.”

- Simply supported to continuous conversion involves removing deck pavement at intermediate supports, adding negative moment reinforcement, and pouring new concrete to form a continuous beam system. The negative moment at supports counteracts mid-span moments, reducing deflection and cracking.

- Adding mid-span supports applies to short-span slab bridges by adding piers, braces, or steel props at or near the mid-span, transforming single-span simply supported structures into multi-span systems, effectively shortening the span and reducing peak bending stress.

This approach optimizes the internal force distribution and offers durable strengthening results, significantly improving stiffness and reducing mid-span deflection. However, for “simply supported to continuous” conversion, reinforcement detailing and bonding between old and new concrete are critical, while for added supports, foundation bearing capacity must be sufficient to prevent uneven settlement.

Anchored Sprayed Concrete Method (for insufficient reinforcement and dense cracking)

This method enhances the effective cross-section and reinforcement at the slab bottom, improving flexural and crack resistance. It is suitable for slabs with dense cracking, spalling concrete, or insufficient rebar.

After roughening the concrete surface, a reinforcing steel mesh is anchored and securely connected to the existing reinforcement. Then, shotcrete is applied to form a new composite tension layer, effectively increasing section thickness and reinforcement area.

Advantages include fast construction, strong adaptability, good repair of damaged concrete surfaces, and cost-effectiveness due to readily available materials. However, it is important to control the mix ratio and spraying pressure to ensure concrete compactness and firm bonding between the new and old layers to prevent delamination.

Deck Reconstruction Method (for hinge joint deterioration)

This method specifically addresses cracking at the hinge joints of precast slab bridges by improving deck integrity to ensure coordinated load sharing among slabs.

Common measures include:

- Thickening the deck pavement layer with high-strength or steel-fiber concrete to increase stiffness.

- Adding transverse reinforcement and connecting it firmly with the pre-embedded bars of adjacent slabs to improve load transfer.

- Thoroughly cleaning and recasting cracked hinge joints with high-grade micro-expansive concrete to restore compactness.

This method can be implemented concurrently with deck maintenance, requiring no additional closure time, and effectively restores load transfer, improves deck smoothness, and extends structural service life.

Bearing Repair and Replacement Method (for voided or deteriorated bearings)

This method deals with bearing voids, aging, or damage to restore uniform load transfer between the superstructure and substructure.

The main approaches include:

- Bearing replacement, where damaged bearings are removed and replaced using jacking equipment. New bearings may be rubber or pot bearings.

- Bearing pad adjustment, where shims or pressure grouting are used to restore uniform contact and proper elevation.

- Bearing reinforcement, involving cleaning, derusting, and sealing of slightly damaged bearings to extend service life.

During construction, synchronous jacking control is essential to prevent uneven stresses or new cracking. The new bearing type and installation accuracy must comply with structural design and relevant standards.

Conclusion

Simply supported slab bridge reinforcement should follow the principle of “inspect first, design precisely, construct scientifically.” By diagnosing root causes, accurately analyzing stresses, and selecting the optimal strengthening method, engineers can achieve safe, economical, and durable results. With advancements in materials and construction technologies, future bridge reinforcement will emphasize green, low-carbon, and intelligent monitoring solutions to further improve performance and longevity.

For tailored reinforcement design, it is recommended to consult a qualified professional bridge design institute.