Pot bearings are often called the “invisible bodyguards” of modern bridges. Though compact and inconspicuous, they play a vital role in ensuring bridge stability, load transfer, and seismic resilience. With their high load-bearing capacity, large displacement range, and strong damping performance, pot bearings are indispensable components in today’s bridge engineering.

Core Functions of Pot Bearings

1. Heavy Load Capacity

Pot bearings can withstand vertical loads up to 50 MN, equivalent to the weight of 5,000 elephants. Such immense strength makes them ideal for long-span structures like the Yangtze River Bridge, where they support the daily impact of thousands of heavy trucks.

2. Displacement Adjustment

The dual-direction sliding design allows a movement range of ±200 mm, accommodating bridge expansion and contraction caused by temperature changes while maintaining smooth displacement even under extreme conditions.

3. Seismic Performance

Equipped with energy-dissipating plates and damping rings, pot bearings can achieve a 60% vibration reduction rate. In a real-world case from southwest China, a highway bridge equipped with this type of bearing remained stable during a magnitude 5.8 earthquake, keeping deck acceleration below 0.15 g, far below the danger threshold.

4. Rotational Adaptability

The steel pot and elastomeric pad enable 0.02 radians of rotation—smooth and controlled—effectively distributing bending stress and maintaining structural integrity.

Types and Application Scenarios

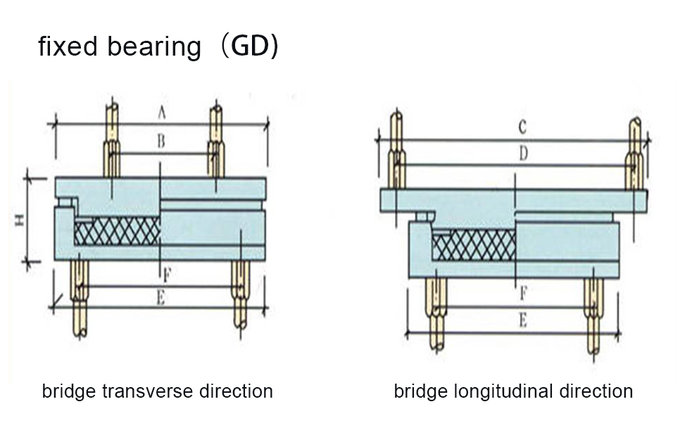

GD Fixed Type

Resists horizontal forces up to 20% of its vertical load, doubling the strength of standard bearings. Perfect for bridges in seismic zones where stability is critical.

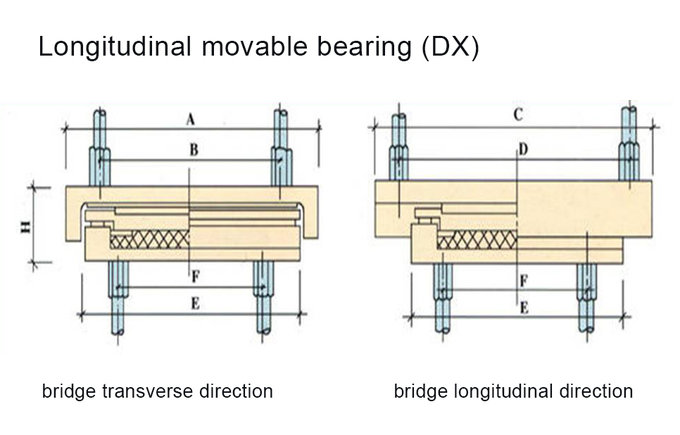

DX Single-Directional Type

Allows longitudinal sliding while restricting lateral movement—ideal for curved bridges or ramp structures that experience asymmetric stress patterns.

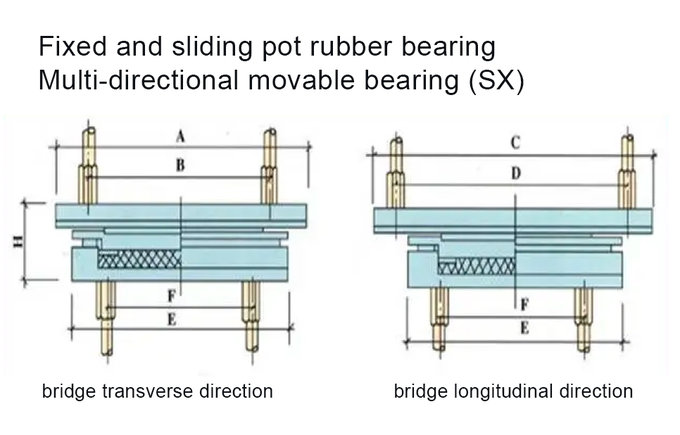

SX Multi-Directional Type

Supports all-directional movement for complex bridge geometries such as skew or special-shaped bridges. This type is used in iconic projects like the Hong Kong–Zhuhai–Macao Bridge.

Selection Guide:

| Bridge Type | Recommended Bearing Type |

| Regular bridges | GD Fixed Type |

| Bridges with large temperature deformation | DX Single Sliding Type |

| Seismic regions | GD Type + Damping device |

| Skew/Complex bridges | SX Multi-directional Type |

| Cold regions (−40°C) | F-Series cold-resistant model |

Performance Under Extreme Environments

Pot bearings are engineered to perform between −40°C to +60°C, ensuring stability from the freezing northeast to tropical climates.

The F-series cold-resistant bearings use a specialized silicone lubricant with a friction coefficient ≤ 0.04, ensuring smooth movement even under icy conditions.

Key Technical Highlights

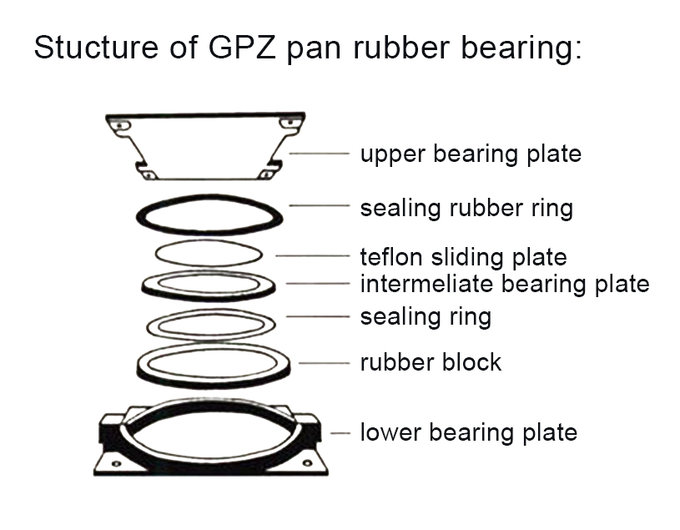

- Extended Service Life — Triple-sealing design prevents leakage and extends lifespan from the usual 30 years to over 50 years.

- Ultra-Low Friction Loss — Uses PTFE and stainless-steel plates for minimal wear, reducing friction below that of a smartphone screen protector.

- High Installation Precision — Installation tolerance ≤ 0.1 mm, finer than a human hair; deviation beyond this may cause structural stress concentration.

Installation Guidelines

- Horizontal deviation ≤ 0.1 mm/m, vertical deviation ≤ 0.3% for uniform force distribution.

- Anchor bolts must be torque-calibrated to prevent loosening and instability.

- Record ambient temperature during installation as a reference for future inspections.

Selection & Maintenance Notes

- For regions below −25°C, use cold-resistant bearings to prevent rubber cracking.

- Sea-crossing bridges require an extra stainless-steel anti-corrosion layer.

- Accurately calculate bridge displacement and match with expansion joint design to prevent operational failure.

Case Studies

Case 1: Yangtze River Bridge

Used GPZ (II) 15.0SX bearings with 2000 mm expansion joints, operating steadily for over 15 years. The installation used steel fiber concrete leveling and temperature-adjusted gaps for long-term precision.

Case 2: Yunnan High-Speed Rail Bridge

Installed GPZ seismic bearings, which kept acceleration below 0.15 g during a magnitude 5.8 earthquake, ensuring bridge safety and continuous operation.

(Image ALT examples: “Pot bearing installation on long-span bridge”, “Seismic performance of bridge bearing under vibration test”)

Inspection and Maintenance Guidelines

- Regular Inspection:

- Every 2 years for regular bridges, annually for long-span bridges.

- Use laser displacement sensors to measure eight perimeter points following GB/T7759 standards.

- Component Maintenance:

- Inspect sealing rings before each rainy season; replace if aging exceeds 2 mm.

- Apply silicone grease regularly to maintain low-friction performance.

- Professional Assessment:

- If deformation exceeds 0.5‰ of outer diameter, contact qualified inspectors for testing or replacement.

Future Trend — Smart Bearings and AI Inspection

The future of bridge bearings lies in intelligent monitoring. Integrated sensors within pot bearings will continuously track deformation, temperature, and vibration—sending real-time alerts when anomalies occur.

Riebo’s AI Bridge Inspection Solution complements this vision by enabling:

- Drone-based data acquisition of bearing seats and bridge joints.

- AI defect recognition for cracks, corrosion, or displacement.

- Digital twin integration for predictive maintenance and lifecycle management.

Together, these technologies transform bridge bearings from passive components into active guardians of structural safety.

Conclusion

Pot bearings may be hidden beneath the bridge deck, but their importance to structural safety is undeniable. When combined with AI-powered inspection and intelligent monitoring, they become part of a smarter, safer, and more resilient bridge ecosystem.