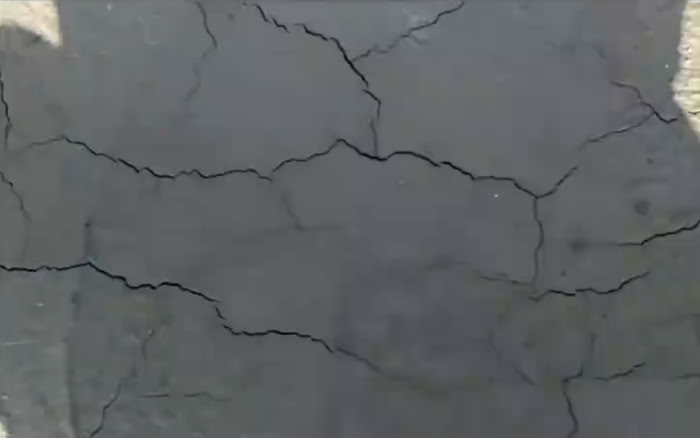

Bridge deck pavement plays a vital role in protecting the bridge deck slab, distributing vehicle loads, and extending the service life of the structure. However, in recent years, cracks on concrete bridge deck surfaces have become increasingly common — even in newly built bridges. These cracks not only affect the bridge’s appearance but can also allow water ingress, accelerate corrosion, and compromise long-term durability.

This article explores the main causes of bridge deck pavement cracking, preventive measures, and effective repair techniques, combining structural engineering knowledge with modern bridge inspection insights.

1. What Is Bridge Deck Pavement?

Bridge deck pavement refers to the protective layer applied on top of the bridge deck. It serves several key purposes:

- Protects the deck slab from vehicle wear and environmental exposure

- Distributes wheel loads evenly

- Improves surface smoothness and driving comfort

- Prevents water infiltration and corrosion of reinforcing steel

Common types of bridge deck pavement include cement concrete, asphalt concrete, and polymer-modified overlays. The selection depends on bridge type, climate conditions, and traffic load.

2. Common Causes of Bridge Deck Pavement Cracking

Bridge deck cracks generally originate from three main categories: design issues, construction problems, and environmental influences.

(1) Design-related Issues

Improper structural design is one of the most common root causes of cracking.

- Inadequate reinforcement spacing or bar diameter – large gaps or oversized rebar can cause uneven stress distribution.

- Improper concrete thickness or mix ratio – insufficient strength or poor bonding between layers increases cracking potential.

- Temperature and shrinkage constraints – concrete tends to shrink and expand; if movement is restricted, tensile stress causes micro-cracks.

- Poor transition details – sharp geometric changes or weak bonding between the deck and approach slab promote cracking.

(2) Construction-related Issues

Cracks often form due to poor workmanship and uncontrolled material behavior during construction.

- Substandard raw materials – aggregates with high mud or moisture content reduce concrete strength.

- Improper concrete curing – inadequate temperature or moisture control during curing causes shrinkage cracks.

- Insufficient vibration or layering errors – poor compaction leads to voids and weak interfaces between layers.

- Premature traffic loading – allowing vehicles before the pavement reaches design strength accelerates microcrack formation.

(3) Environmental and Service Factors

Even well-designed decks face environmental stresses over time.

- Temperature fluctuation and drying cycles cause expansion and contraction fatigue.

- Heavy traffic loading introduces repetitive dynamic stress.

- Water infiltration through aged waterproof layers leads to corrosion and freeze–thaw cracking.

- Deicing chemicals and UV radiation further accelerate pavement deterioration.

3. Crack Repair and Maintenance Solutions

Crack repair must address both surface appearance and structural integrity. Depending on crack severity, different repair methods can be applied.

(1) Surface Sealing

For shallow or early-stage cracks, sealing with epoxy resin or acrylic sealants prevents water intrusion and protects steel reinforcement from corrosion.

(2) Injection Repair

For deep or structural cracks, low-pressure grouting with polymer resin restores the bond between cracked sections and strengthens the deck.

(3) Overlay Replacement

When the pavement is extensively cracked or delaminated, the damaged layer should be milled and resurfaced with high-performance materials such as polymer-modified concrete.

(4) Preventive Maintenance

- Perform regular UAV bridge inspections to identify early cracking.

- Monitor deck surface conditions with AI-based image analysis.

- Improve drainage and waterproofing layers to prevent moisture-related cracks.

- Apply anti-cracking admixtures during deck resurfacing projects.

4. Case Example: Bridge Deck Crack Repair in Practice

During a recent bridge pavement maintenance project, inspectors discovered extensive microcracks across the concrete surface. After evaluation, the following repair sequence was implemented:

- Crack mapping and classification

- Surface cleaning and moisture control

- Epoxy injection and surface sealing

- Final resurfacing and curing under controlled conditions

Post-repair inspections confirmed significant improvements in waterproofing, surface strength, and driving comfort.

5. Conclusion

Bridge deck pavement cracking is one of the most common yet preventable issues in bridge maintenance. By addressing design precision, construction quality, and routine inspections, engineers can minimize long-term structural deterioration.

With AI-powered UAV inspection and 3D bridge modeling, RIEBO provides integrated solutions for bridge deck crack detection, maintenance, and lifecycle management, ensuring safer and longer-lasting bridge infrastructure worldwide.