Bridge corrosion inspection plays a critical role in ensuring the durability and safety of reinforced concrete bridges. Over time, environmental exposure—especially to moisture, chloride ions, and air pollutants—can lead to steel reinforcement corrosion, one of the most common and destructive bridge deterioration problems. Corrosion not only reduces structural capacity but also causes cracks, delamination, and spalling of the concrete cover, threatening long-term bridge integrity.

1. Causes and Mechanism of Steel Reinforcement Corrosion

Corrosion in reinforced concrete is essentially an electrochemical process. Under normal alkaline conditions, steel bars are protected by a thin passive oxide film. However, this protective layer can be destroyed when:

-

Carbonation lowers concrete alkalinity;

-

Chloride ions penetrate from de-icing salts, seawater, or contaminated aggregates;

-

Or cracks and porous concrete allow oxygen and moisture to reach the rebar.

Once the passive film is broken, rust (iron oxide) forms and expands—its volume can be up to 6–10 times that of the original steel. This expansion creates internal pressure, leading to cracking and flaking of the concrete surface, accelerating further corrosion.

2. Bridge Corrosion Inspection Methods

2.1 Visual Inspection

Visual inspection remains the first line of bridge corrosion assessment. Inspectors observe surface rust stains, cracks, water leakage, or delamination that often indicate rebar corrosion beneath the surface. For high-clearance bridges, drones and telephoto lenses can be used to capture detailed imagery for analysis.

While quick and cost-effective, this method relies heavily on inspector experience and is best used for preliminary screening before applying advanced non-destructive testing (NDT).

2.2 Non-Destructive Testing (NDT) Techniques

Ultrasonic Testing (UT)

Ultrasonic pulse velocity (UPV) inspection evaluates the internal condition of concrete. By measuring wave speed and attenuation, inspectors can detect voids, delamination, and corrosion-induced cracks within the structure. Changes in wave propagation characteristics help identify the severity and location of corrosion damage.

Electrochemical Testing

Half-cell potential measurement is a widely used method for corrosion assessment. It measures the electrical potential difference between a reference electrode and the embedded steel.

-

A more negative potential indicates higher corrosion activity.

-

Combined with resistivity measurements, it helps determine corrosion risk zones.

This technique is fast, non-invasive, and provides quantitative corrosion data.

2.3 Indirect and Chemical Analysis

Chloride Ion Content Test

Determining chloride concentration is essential for evaluating corrosion risk. The silver nitrate titration method is commonly used to measure chloride levels in concrete samples. When chloride content exceeds 1% of cement weight, steel corrosion activation becomes highly probable.

Concrete Resistivity Measurement

This method measures the electrical resistance of concrete, which reflects its ability to transmit ions and moisture.

-

Low resistivity = high corrosion probability.

-

High resistivity = better durability.

It complements electrochemical testing and helps map corrosion-prone areas.

3. Corrosion Prevention and Maintenance Strategies

3.1 Design Stage Prevention

-

Select durable materials: Use high-density concrete and corrosion-resistant steel.

-

Optimize mix design: Add silica fume, fly ash, or slag to improve chloride resistance and reduce permeability.

-

Ensure proper cover thickness: Adequate concrete cover provides physical protection and maintains alkalinity.

3.2 Construction Quality Control

-

Maintain proper curing and compaction to avoid voids and cracks.

-

Prevent contamination of rebar with oil, rust, or chloride.

-

Implement strict supervision to ensure compliance with design and durability requirements.

3.3 Maintenance and Protection

-

Conduct regular corrosion inspections using drones, NDT, and potential mapping.

-

Apply protective coatings (e.g., epoxy or polyurethane) to isolate steel from corrosive agents.

-

Use cathodic protection systems to maintain a stable potential on steel surfaces.

-

Control traffic loads and prevent overloading to reduce stress-induced cracking and corrosion risk.

3.4 Advanced Technologies

To enhance bridge corrosion detection and maintenance, integrating intelligent inspection systems with new materials has become essential.

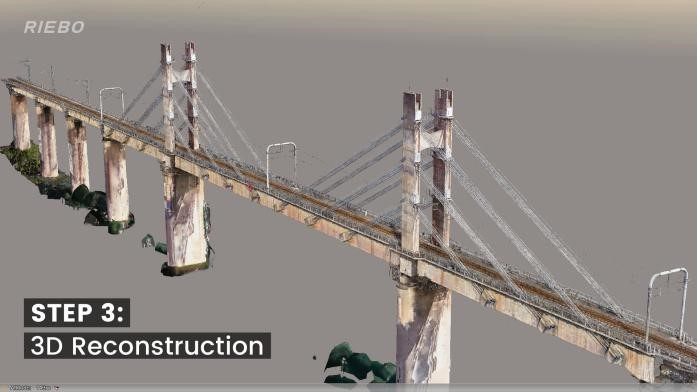

The Riebo UAV Bridge Inspection Solution enables high-efficiency corrosion monitoring by combining specialized inspection cameras, AI-based image analysis, and multi-platform UAV compatibility. During bridge inspections, it captures high-resolution visual and infrared data to identify corrosion stains, rust layers, and surface cracking—especially in areas difficult for manual access.

When integrated with Digital Twin platforms, inspection data can be visualized in 3D for corrosion mapping and lifecycle management. This helps engineers track deterioration trends, quantify corrosion severity, and plan maintenance more scientifically.

Together with innovations such as smart anti-corrosion coatings, electrochemical protection, and durable concrete materials, Riebo’s system supports a proactive, data-driven approach to bridge corrosion prevention and structural health management.

Conclusion

Bridge corrosion inspection is a key component of structural health monitoring and asset management. By combining visual inspection, NDT technologies, and electrochemical assessment, engineers can accurately identify corrosion layers and deterioration patterns before major damage occurs.

Through preventive design, strict construction control, and intelligent maintenance, the service life of reinforced concrete bridges can be significantly extended—ensuring safer, more resilient infrastructure for decades to come.