What Is AI Bridge Inspection?

AI bridge inspection is no longer a future concept—it is already being widely applied in the field of smart infrastructure management. Many engineering teams and solution providers, including Riebo’s AI bridge inspection system, are leveraging deep learning and computer vision to conduct automated crack detection, defect analysis, and structural monitoring.

AI Bridge Inspection is an automated detection technology based on artificial intelligence (AI) and computer vision, designed to identify structural defects such as cracks, spalling, and corrosion on bridges. Compared with manual inspection, AI-based inspection offers higher efficiency and accuracy while enabling quantitative analysis and long-term health monitoring of bridge structures.

At the core of AI bridge inspection systems lie deep learning (DL) and convolutional neural networks (CNNs). These models “learn” the visual and geometric features of cracks, honeycombing, surface pitting etc…, enabling precise detection of subtle defects directly from bridge images.

Technical Principles of AI Bridge Crack Detection

(1) Data Collection and Annotation

High-resolution cameras or UAVs (drones) are used to capture surface images of bridges. Crack areas in these images are manually annotated pixel by pixel.

Next, techniques such as crack seed-point segmentation and data augmentation are applied to divide the original images into smaller sample blocks, producing a large and diverse dataset. This process enhances the model’s ability to recognize cracks of varying scales and improves generalization. The size of these image blocks is not fixed—different research teams define block dimensions based on image resolution, computing power, and project requirements.

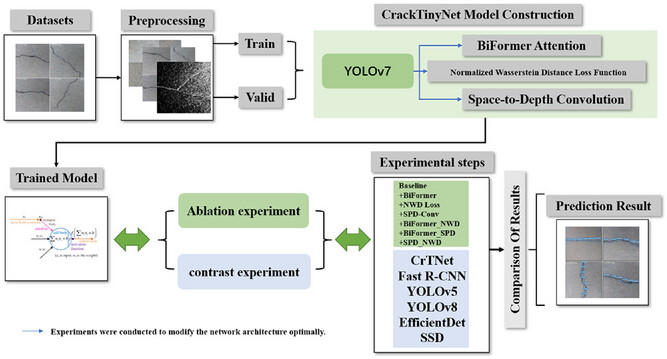

(2) Deep Learning Models: U-Net and YOLOX Applications

In the field of AI bridge inspection, two deep learning architectures—U-Net and YOLO series models (e.g., YOLOX)—are widely adopted, each serving different purposes in crack detection.

- U-Net Model (Semantic Segmentation)

U-Net is ideal for pixel-level segmentation tasks, capable of delineating fine crack contours and estimating crack width. Its skip connectionstructure combines shallow and deep feature maps, preserving critical texture and edge details. This makes U-Net particularly suitable for high-precision crack mapping in engineering applications. - YOLOX Model (Object Detection)

YOLOX is an end-to-end real-time detectionalgorithm known for its speed and inference efficiency. It is highly effective for large-scale bridge surface inspections, such as decks, pylons, and girders, where rapid crack or defect localization is required. When combined with segmentation algorithms, YOLOX performs the “detection + segmentation” two-stage AI inspection process, first identifying potential defect areas and then refining them through models like U-Net.

(3) Post-Processing for Accuracy

AI detection results often require post-processing to eliminate false positives and improve continuity. Common techniques include:

- Length threshold filtering– Removes short and noisy pseudo-cracks;

- Minimum spanning tree (MST) connection algorithm– Restores continuity between crack segments;

- Morphological dilation and smoothing– Refines edges to align with real structural characteristics.

After refinement, metrics such as mean Average Precision (mAP) and mean Intersection over Union (mIoU) significantly improve, delivering more consistent crack detection performance.

(4) Large-Image Optimization and Detection Speed

For high-resolution bridge images, AI systems use a mirror–overlap–segmentation strategy to ensure complete and continuous detection. In addition, a background subtraction algorithm is employed to pre-filter non-crack regions, substantially accelerating the overall inspection process and system response time.

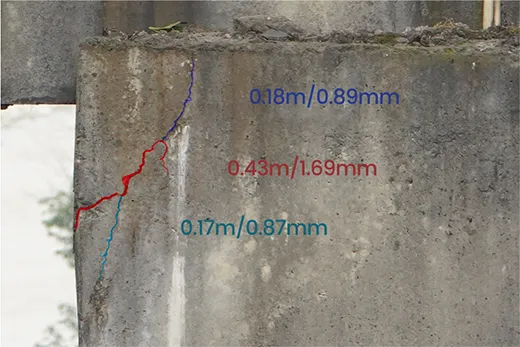

(5) Intelligent Crack Width Measurement

The AI system can automatically measure crack width using a multi-directional search algorithm.

By scanning outward from the crack’s centerline in multiple directions and calculating pixel-to-physical scale ratios, it determines the actual crack width. Experimental results show a measurement error below 0.05 mm, meeting stringent engineering accuracy requirements.

Advantages of AI Bridge Inspection

| Advantage | Description |

| High precision | Detects micro-level cracks beyond manual visibility |

| Automation & Intelligence | Fully automated process, ideal for UAV inspection |

| High efficiency | Up to 10–50× faster than manual inspection |

| Data visualization | Generates crack distribution maps and width statistics |

| Multi-scenario adaptability | Applicable to concrete, steel structures, tunnels, and more |

Conclusion

Using advanced deep learning models such as U-Net and YOLOX, AI bridge inspection achieves both intelligent defect recognition and quantitative analysis. It automates the entire process—from crack detection to fine segmentation—while greatly improving accuracy and operational efficiency. As algorithms evolve and computing hardware advances, AI-based bridge inspection will become the mainstream solution for bridge maintenance and safety assessment worldwide.