In today’s rapid development of oblique photogrammetry technology, the optical performance of lenses often draws the most attention. However, the true core that supports precise modeling—synchronization control technology—often exists as a “hidden parameter.” This technology directly determines the accuracy and efficiency of UAV photogrammetric data, and its importance in large-scale mapping such as 1:500 or 1:1000 is no less than that of the optical resolution of the lenses.

This article uses Riebo’s flagship product DG4pros as a core case, analyzing synchronization technology in oblique cameras from the aspects of technical needs, problem origins, breakthroughs in R&D, and real-world applications, to fully explain its underlying logic and development path.

Why Synchronization Matters in Oblique Cameras

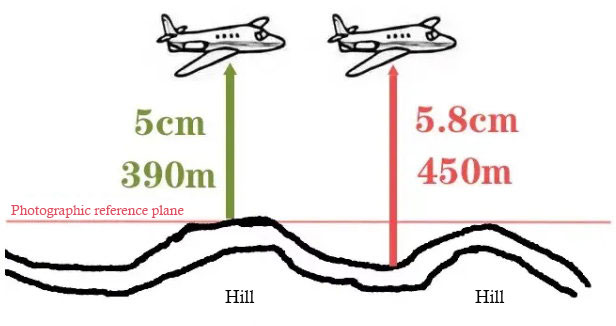

An oblique camera uses five lenses (one nadir + four oblique) to capture ground data from multiple angles. Ideally, when the UAV sends a trigger signal, all five lenses should expose at exactly the same time. In reality, even a few milliseconds of delay can translate into tens of centimeters of error in positioning data.

Riebo’s DG4pros sets a new benchmark. Even at high-speed operations with a 0.6s exposure interval, it keeps inter-lens sync error within 2 ms. At a UAV speed of 10 m/s, this means positional offsets of less than 1 cm—crucial for urban 3D modeling, cadastral surveys, and fine-scale topographic mapping.

Without proper synchronization, older cameras showed position errors of 60–100 cm in aerial missions, making them unsuitable for precision mapping.

The Hidden Cause of Synchronization Errors

Why does desynchronization occur among five lenses? The core issue lies in the mismatch between camera processing speed and scene complexity.

When triggered, each camera must complete:

- Image sensing

- Bayer demosaicing (color reconstruction)

- Data compression & storage

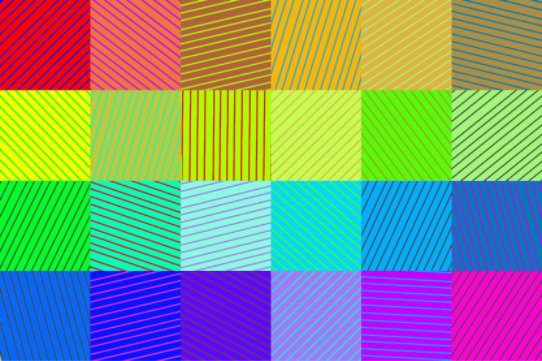

The time consumption of these steps is not fixed—it is heavily influenced by scene texture complexity:

- The more complex the texture (urban clusters, dense vegetation), the greater the amount of high-frequency detail, exponentially increasing compression workloads.

- The richer the colors (farmlands, commercial districts), the heavier the Bayer demosaicing load.

- When data processing time exceeds trigger intervals, the camera fails to respond in time, causing exposure delays—or worse, frame drops (skipping shots).

To quantify this, Riebo added a “feedback timer” during DG4pros development, testing across four scene complexities and five exposure frequencies.

A: Consistent color and texture, low-frequency data image

B: Inconsistent colors, consistent textures, low-frequency data images

C: Consistent colors, inconsistent textures, high-frequency data images

D: Inconsistent colors and textures, high-frequency data images

Results showed:

| Scene Texture | 3s Interval | 2s | 1s | 0.7s | 0.6s |

|---|---|---|---|---|---|

| A: Uniform color/texture | 5–10 ms | 5–10 ms | 5–10 ms | 5–10 ms | 5–10 ms |

| B: Color varied / texture uniform | 5–10 ms | 8–12 ms | 8–12 ms | 15–25 ms | 20–30 ms |

| C: Color uniform / texture complex | 15–25 ms | 15–25 ms | 15–25 ms | 25–35 ms | 30–50 ms |

| D: Color & texture both complex | 25–35 ms | 25–35 ms | 30–35 ms | 30–35 ms | 40–60 ms (frame drops after 500×1000 photos) |

Findings: the higher the exposure frequency and the more complex the texture, the greater the synchronization delay, with risks of frame loss. In the most complex case (D, at 0.6s intervals), sync delays hit 60 ms, which at 10 m/s UAV speed means a 60 cm position error—unacceptable for precision mapping.

Synchronization Control Principle: Feedback Compensation Against Time Lag

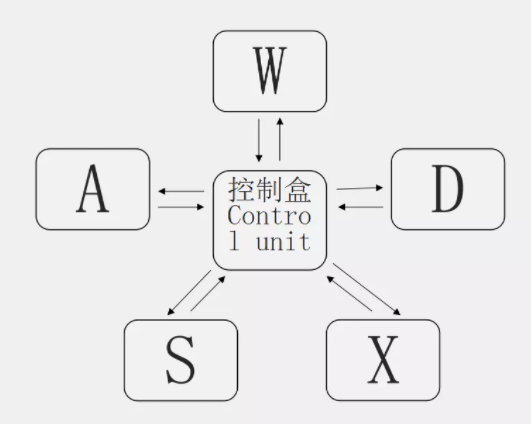

To solve this, Riebo developed a feedback-controlled synchronization system, based on “real-time monitoring & dynamic compensation”:

- Time-lag monitoring: a timing module records the difference between trigger signal and actual exposure time (T-value).

- Sync judgment: if all T-values ≤ threshold (e.g. 2 ms), exposure is synchronous; otherwise, flagged as deviation.

- Dynamic compensation: in the next trigger, the control module pre-shifts the lagging lens shutter by its T-value (e.g. if 3 ms late, next trigger fires 3 ms earlier).

This reduces but does not eliminate desynchronization. Why? Because processing times vary with texture complexity, and fixed compensation parameters could cause worse disruptions. Thus, current technology remains passive compensation—only correcting after deviation occurs—but it already meets most high-precision mapping needs.

In real projects, DG4pros’ maximum positional offset after aerial triangulation was 4.37 cm (at 9.8 m/s flight speed, 4.45 ms sync error)—far below the 60–100 cm of early products, meeting 1:500 mapping accuracy.

Synchronization Technology + PPK: Boosting Field Efficiency

In photogrammetry, PPK (Post-Processed Kinematic) enhances positioning accuracy. But its effectiveness depends on camera synchronization—if lenses are asynchronous, PPK’s high-frequency differential data lose meaning.

Main integration schemes:

| Scheme | Logic | Advantage | Disadvantage |

|---|---|---|---|

| Single-lens trigger PPK | PPK tied to one lens trigger | Simple, low-cost | Only accurate for one lens; others desynchronized |

| Multi-lens PPK tagging | Separate PPK signals for each lens | Accurate | Limited compatibility, higher cost |

| Average sync feedback | Uses averaged T-values from sync controller | Precise, universal | Complex logic, higher R&D cost |

Thus, claims like “100Hz PPK boards enable GCP-free mapping” are misleading—without sync control, position offsets (20+ cm) still degrade triangulation accuracy, requiring GCPs.

High-synchronization cameras like DG4pros maximize PPK’s value, reducing 30–50% of GCPs in 1:500 and 1:1000 projects—significantly boosting efficiency.

Key Takeaway

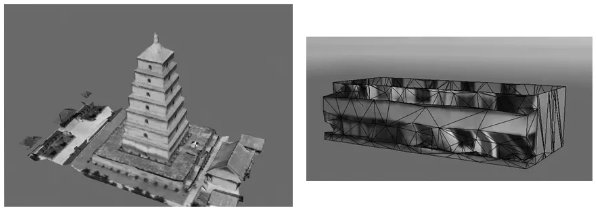

Synchronization is no longer a “hidden parameter.” Alongside optical resolution and endurance, it is now a core metric of oblique mapping camera performance. With innovations like Riebo’s DG4pros and Pro series, the industry is moving toward a new era of:

- Faster data collection

- Higher mapping accuracy

- Smarter, AI-driven 3D modeling

If your projects demand high-precision aerial mapping and 3D reconstruction, choosing a mapping camera with advanced synchronization technology is the key to success.